Camera module automatic function test machine

A camera module and functional testing technology, applied in image communication, television, electrical components, etc., can solve the problems of inability to place camera modules, impact on test accuracy, waste, etc., to improve test work efficiency, save manpower and hardware cost, and the effect of improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

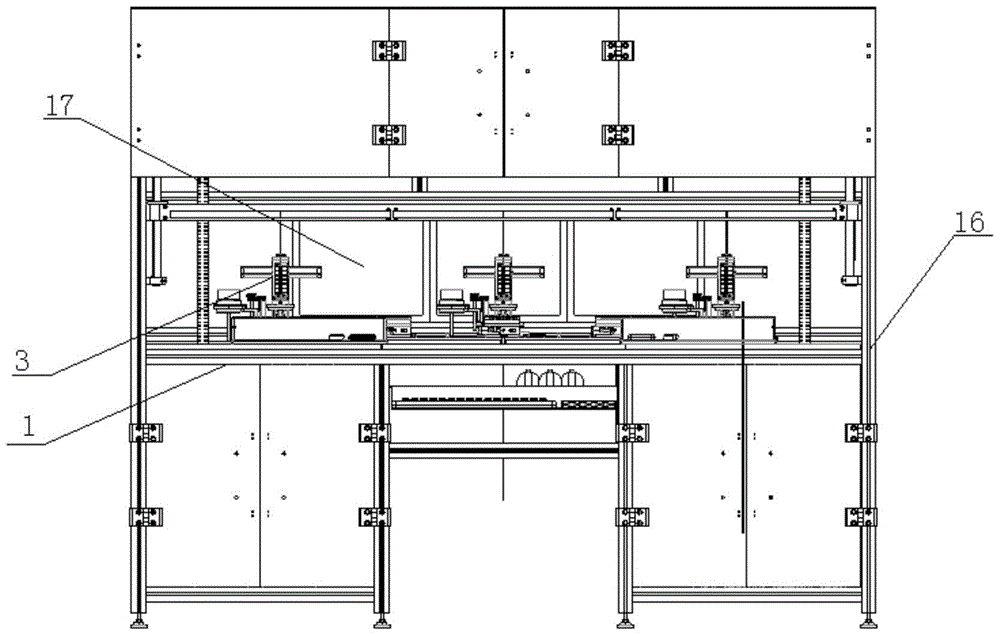

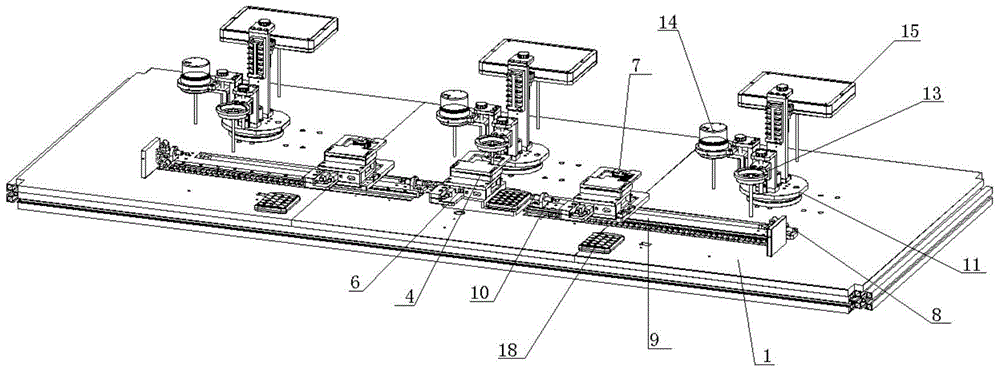

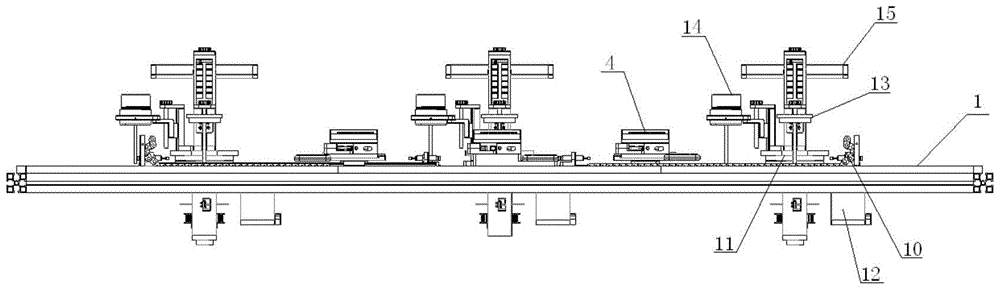

[0030] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a camera module automatic functional testing machine includes a working platform 1 and a controller 2, and at least one rotating testing device 3 is fixed at intervals on the working platform, corresponding to each rotating testing device, on the working platform A positioning fixture 4 and a PC 5 equipped with test control software for carrying and positioning the camera module are provided; the positioning fixture is provided with an image acquisition card 6, and the image acquisition card and the camera module 7 Electrically connected, and the image acquisition card is electromechanically connected with the PC, and the PC is electrically connected with the controller; the rotating test device is positioned with several testers for functional testing of the camera module Unit; the corresponding part of the positioning fixture, the working platform is provided with a corresponding mobile posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com