Container mouth inspection method and device

An inspection method and inspection device technology, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as failure to find defects at the beginning of the thread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

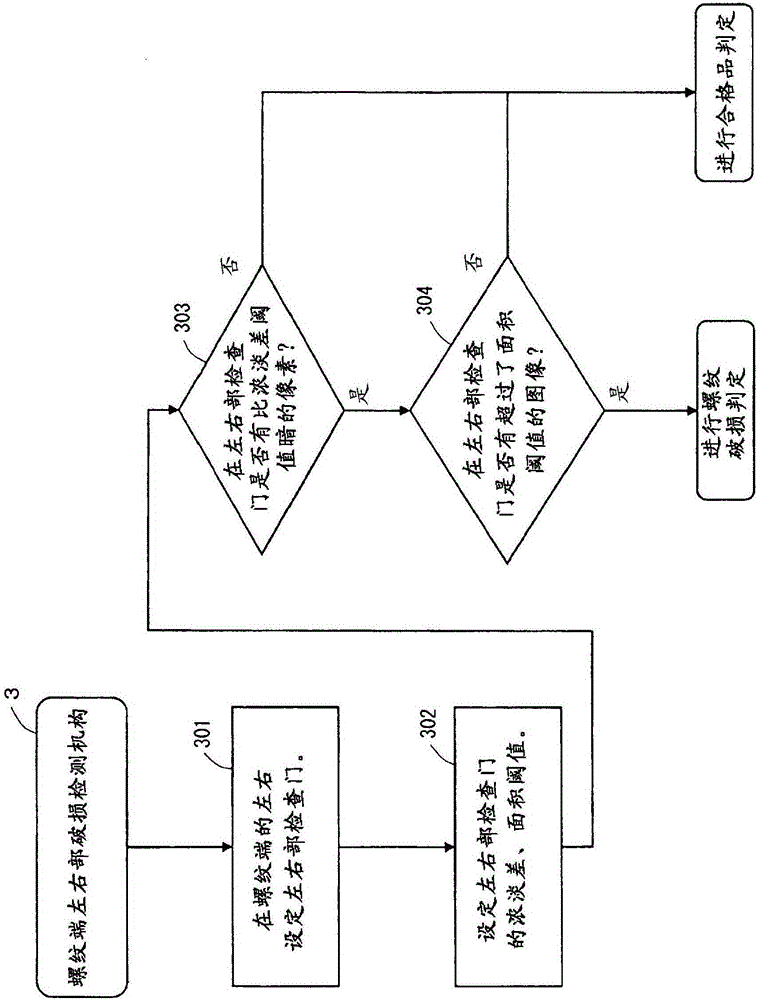

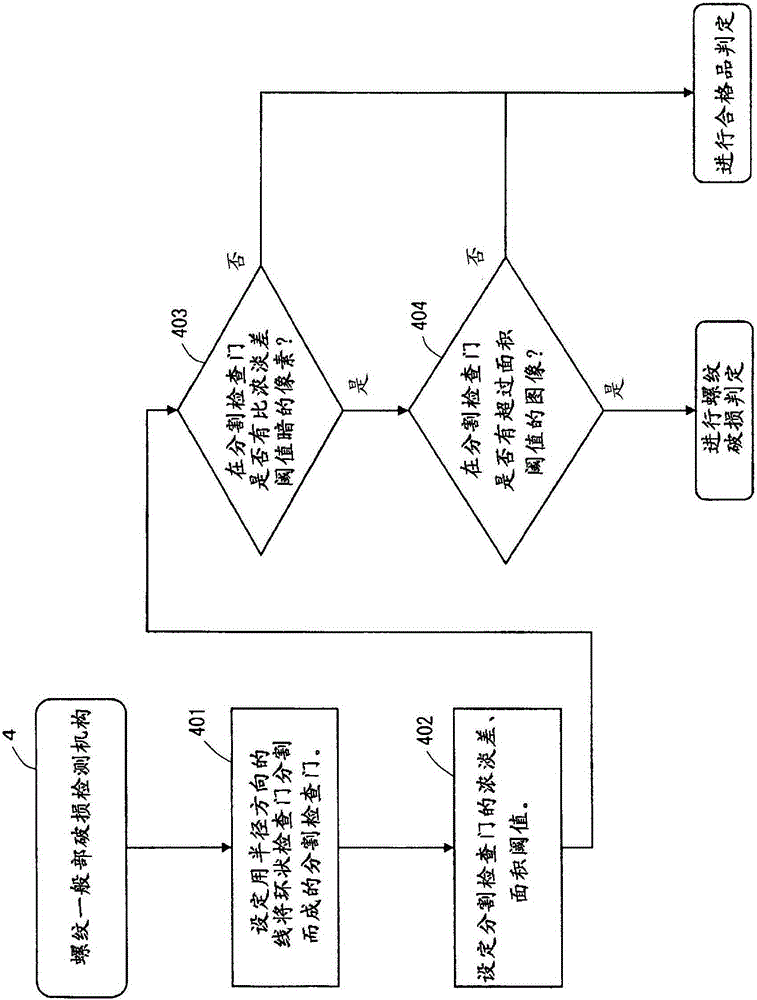

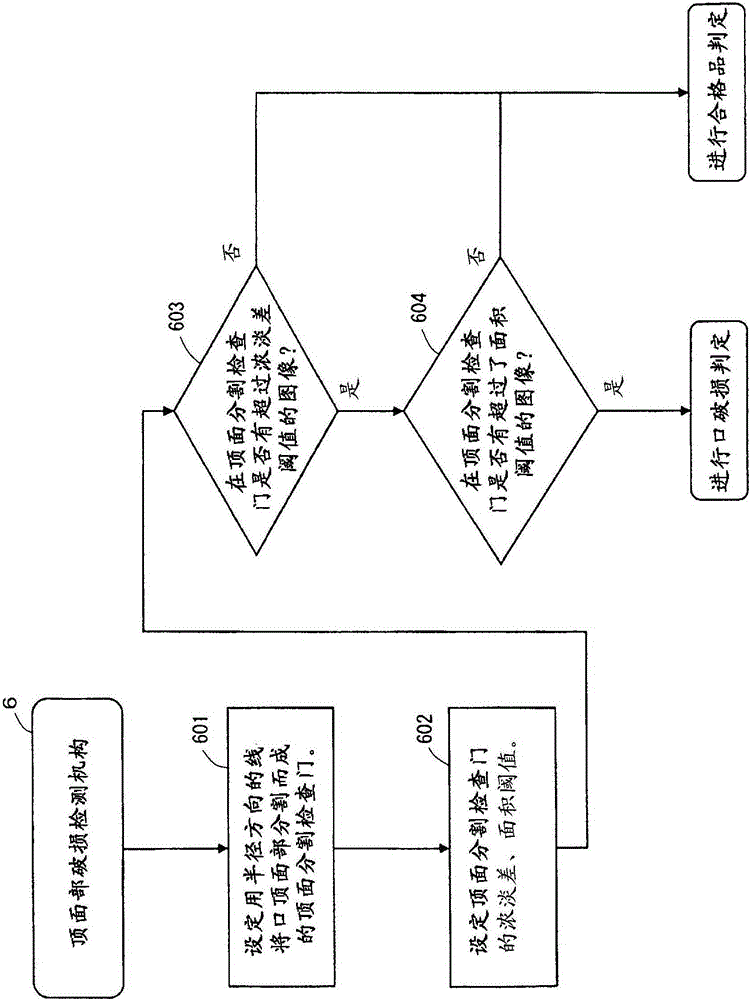

[0050] Such as figure 1As shown, the container mouth inspection device 1 of the embodiment has a camera 11, an illumination 12, a memory 10a, an inspection door detection mechanism 2, a thread end damage detection mechanism 3, a thread general portion damage detection mechanism 4, and a thread outer peripheral portion damage detection mechanism. Mechanism 5, top face damage detection mechanism 6. The inspection door detection mechanism 2 is composed of an annular inspection door detection mechanism 2a and a thread end position detection device 2b. The light from the illumination 12 is reflected by the top surface of the mouth of the container, the thread, etc., and the reflected light is photographed by the camera 11 . The captured images are stored in the memory 10a. The image data read from the memory 10 a is used for the generation of an annular inspection door and the detection of the thread end position by the inspection door detection mechanism 2 . In addition, the im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com