A cable testing device with standard design of lines

A testing device and cable technology, applied in the direction of measuring device, test manufacturing object, fault location, etc., can solve the problems of surface insulation damage, application damage, cable accident and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be described in further detail below in conjunction with the accompanying drawings.

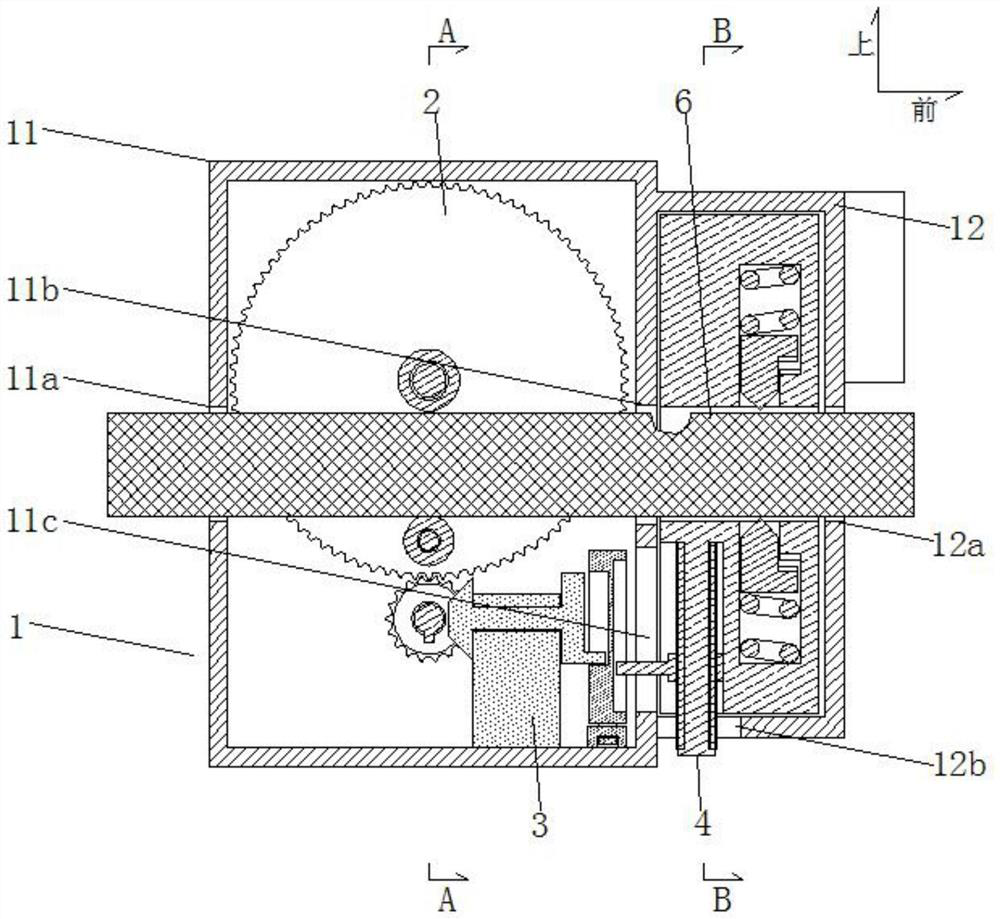

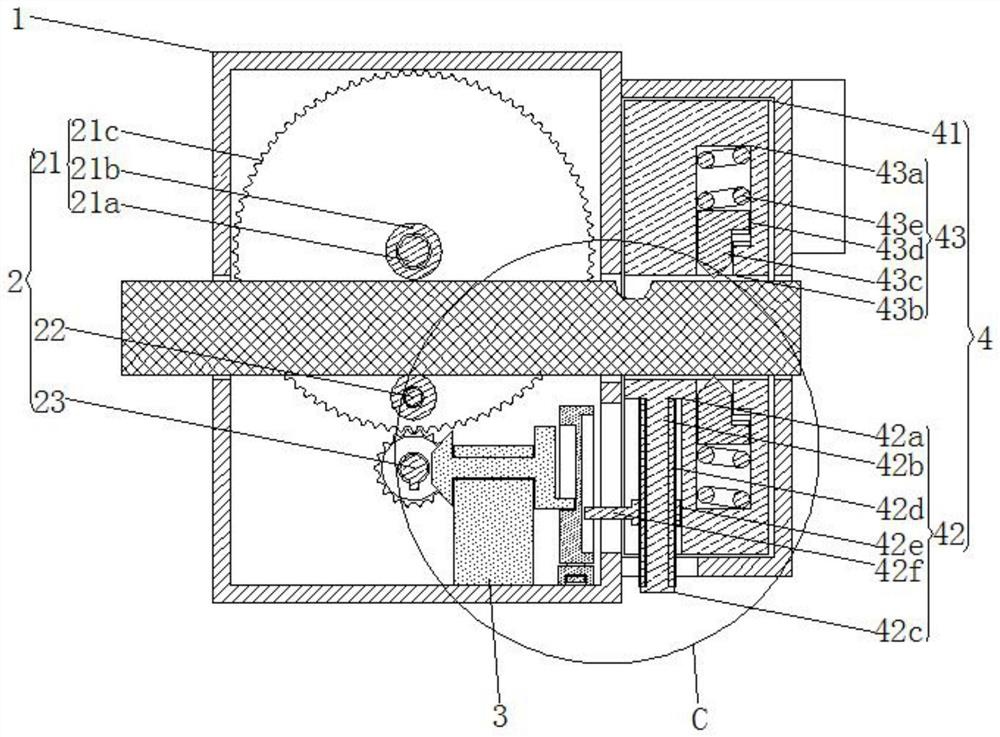

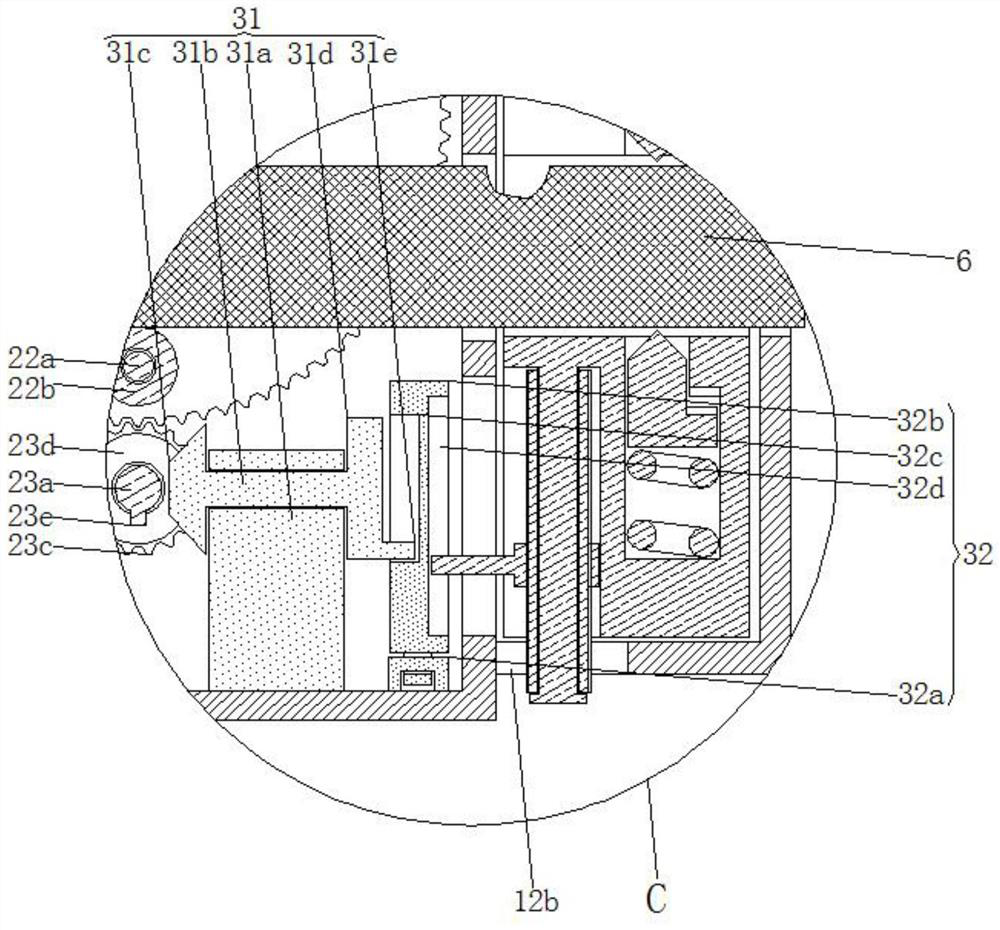

[0063] A cable testing device with standardized circuit design, comprising a device housing 1, an input device 2, a transmission device 3, a trigger device 4, and an alarm device 5;

[0064] The device housing 1 includes a hollow rectangular rear housing 11, the middle of the rear end of the rear housing 11 is provided with a first middle hole 11a, and the middle of the front end of the rear housing 11 is provided with a second middle hole. hole 11b, a swing jack 11c is provided below the front end of the rear housing 11, and a front housing 12 with a circular section is formed on the front end of the rear housing 11, and the front end of the front housing 12 is The middle part is provided with a third middle hole 12a, and the lower end of the front housing 12 is formed with a hand jack 12b, through which the first middle hole 11a, the second middle hole 11b,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com