Novel automatic feed delivery device

An automatic conveying device and feed technology, applied in animal feeding devices, applications, animal husbandry, etc., can solve the problems of unfavorable pig growth, low efficiency, large workload, etc., to reduce hunger stress, provide production benefits, The effect of preventing feed loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

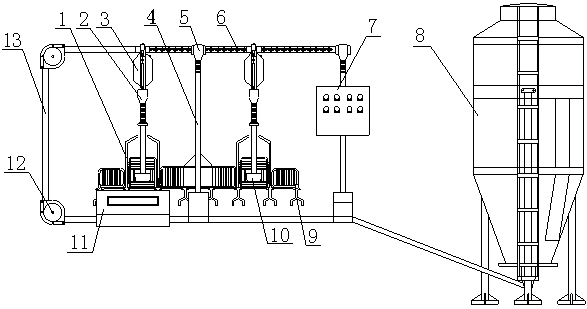

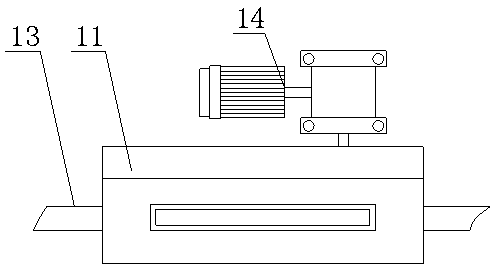

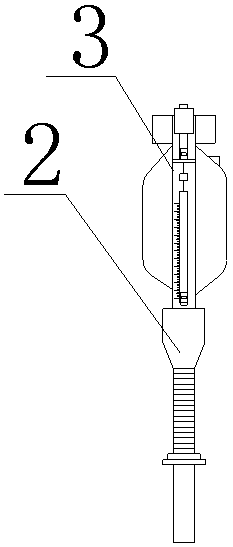

[0013] Such as figure 1 , 2 , 3, and 4 shown, a new type of feed automatic delivery device, including sow positioning column 1, metering cylinder 3, support pipe 4, control box 7, material tower 8, main driver 11, feed delivery pipe 13, described Several sow positioning pens 1 are connected in turn, the bottom is supported by feet 9, a food trough 10 is hung on the sow positioning pen 1, and a support tube 4 is installed on the sow positioning pen 1, and a control box 7 and a support tube 4 are installed on the support tube 4 The top is inserted into the feeding tee 5 to communicate with the feed delivery pipe 13, the feed delivery pipe 13 is covered with the measuring cylinder 3, one end of the feeding pipe 2 is connected to the measuring cylinder 3, and the other end is placed above the trough 10, and the feed delivery pipe 13 is installed There is a main driver 11 with a motor 14, and the main driver 11 is connected to the material tower 8 through a feed delivery pipe 13. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com