Milling method and gear milling device for super-long connecting shaft end face gear

A shaft end face and super-long technology, which is applied in the field of ultra-long shaft end face gear milling and ultra-long shaft end face gear milling devices, can solve the problem of increasing the cost of end face milling and the inability to realize ultra-long shaft end face milling, Low work efficiency and other problems, to achieve the effect of improving production efficiency, shortening the replacement time of spare parts, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

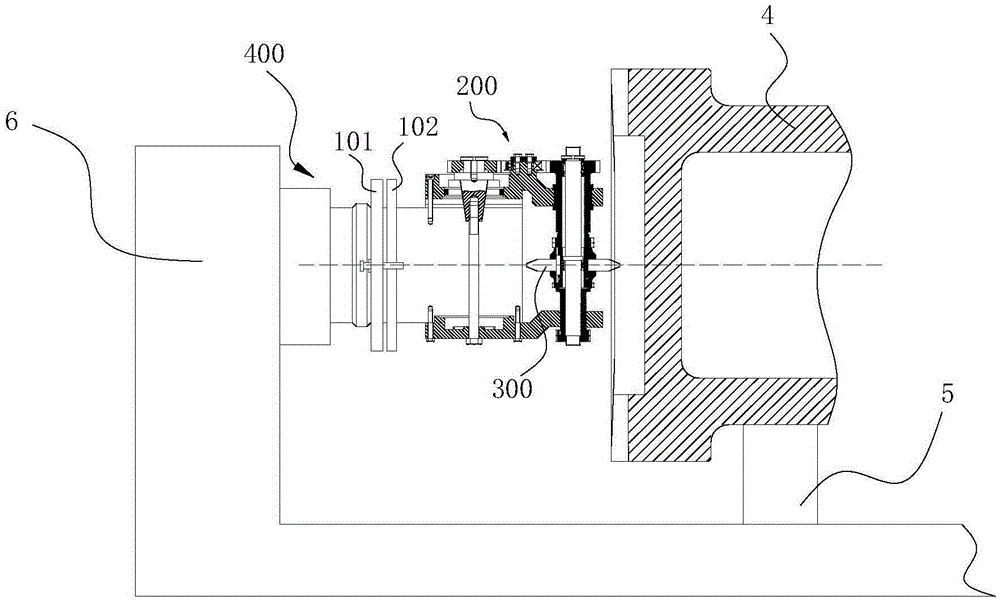

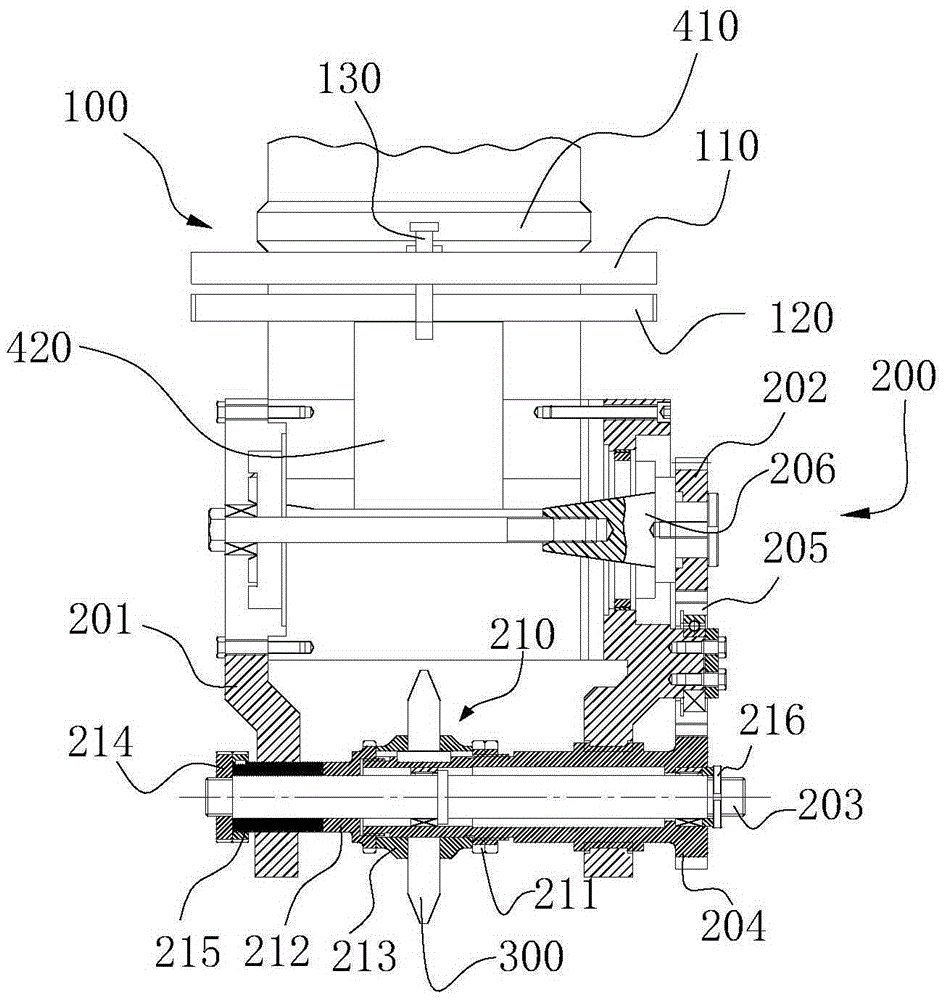

[0052] Such as Figure 1 to Figure 4 As shown in the figure, the milling device for the end face gear of the ultra-long connecting shaft includes a gear dividing mechanism 100, a transmission mechanism 200, a support frame 201, a milling cutter 300 and a right-angle milling head 400;

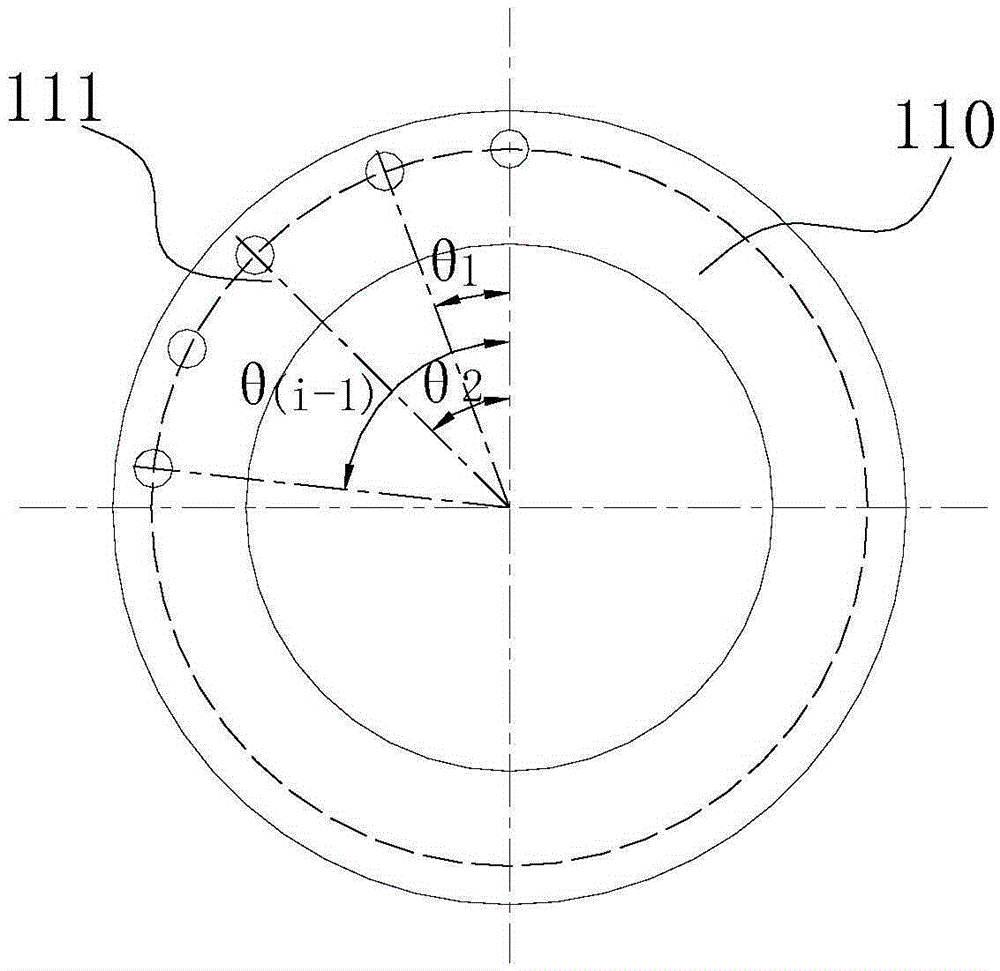

[0053] The tooth dividing mechanism 100 includes a latch 130, a fixed end index plate 110 and a movable end index plate 120, and the fixed end index plate 110 is provided with A index holes 111; Above, the distance from the center of each indexing hole 111 to the center of the fixed-end indexing plate 110 is the same, and the line connecting the center of the i-th indexing hole 111 and the center of the fixed-end indexing plate 110 is connected with the first indexing hole 111 The included angle between the line with the center of the fixed end index plate 110 Wherein i is an integer, and 2≤i≤A; the circumferential surface of the movable end index plate 120 is provided with B indexing grooves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com