An external loop reactor with simultaneous reaction, heat exchange and separation functions

An external loop, reactor technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as difficulty in ensuring the separation efficiency of small particles, affecting the normal operation of the reactor, large footprint or space, etc. Excellent heat transfer characteristics, preventing the interference of asymmetrical bubble flow, and reducing the effect of possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

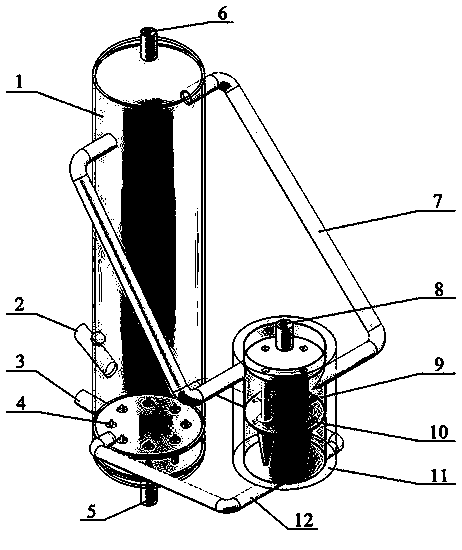

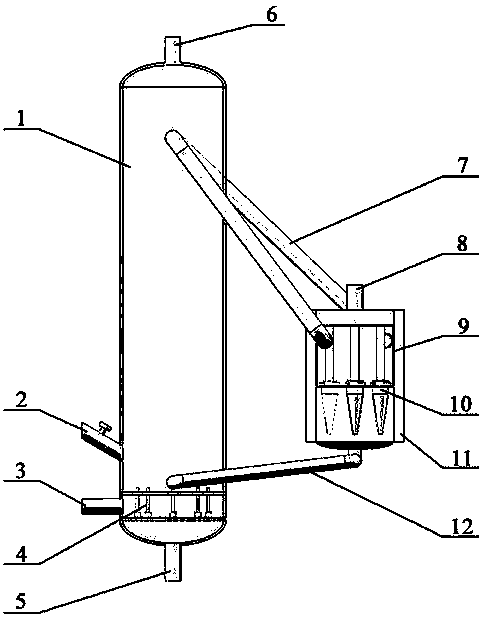

[0018] The present invention is an outer circulation reactor with functions of reaction, heat exchange and separation at the same time, which is an organic combined structure of an outer circulation reactor and a hydrocyclone, consisting of a main reactor (1), a solid feeding port (2 ), liquid inlet (3), gas-liquid integrated distributor (4), gas inlet (5), gas outlet (6), upper downcomer (7), liquid outlet (8), auxiliary separation tank (9), It consists of a hydrocyclone (10), a heat exchanger (11), and a lower downcomer (12).

[0019] like figure 1 As shown, the gas enters the main reactor (1) through the gas-liquid integrated distributor (4), and the solid catalyst particles are added through the solid feeding port (2). After the catalyst is added, the solid feeding port (2) remains closed, and the gas will drive The liquid makes an upward movement, while the solid is fully dispersed under the turbulent action of the liquid. The reacted material enters the auxiliary separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com