Automatic sandblasting mechanism of cooling roller and sandblasting method

A technology of cooling roller and moving mechanism, applied in abrasive jet machine tools, abrasives, metal processing equipment, etc., to achieve the effect of good appearance quality and uniform sandblasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below in conjunction with accompanying drawing:

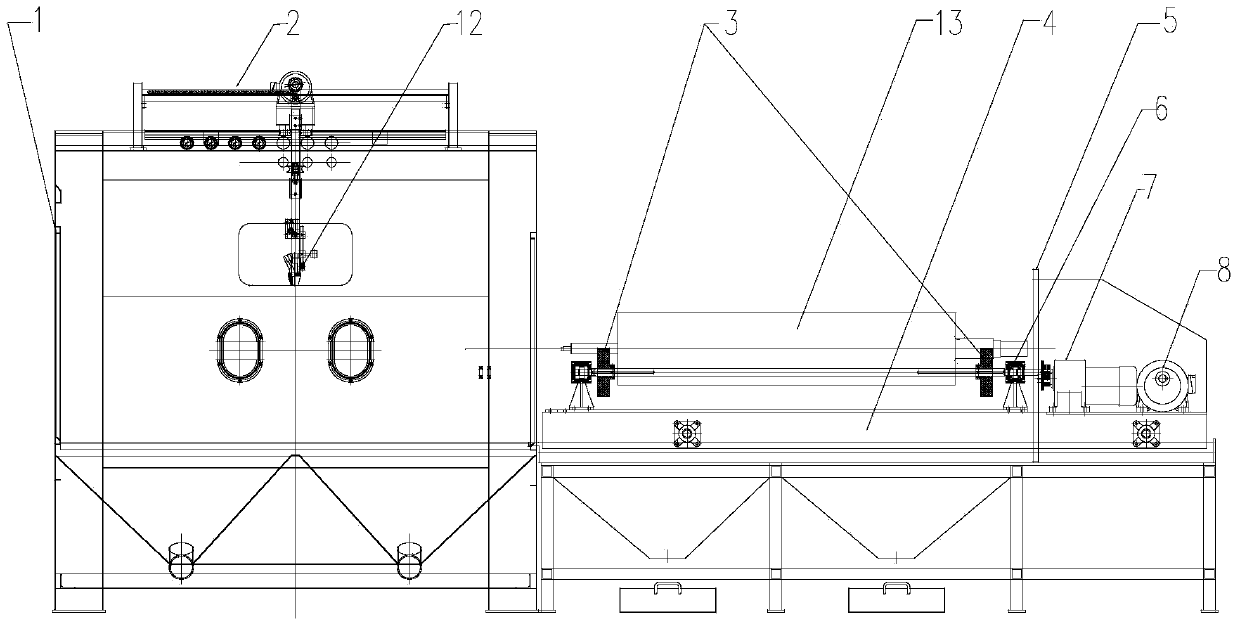

[0021] see figure 1 An automatic sandblasting mechanism for cooling rollers, including a main machine, a spray gun moving mechanism, a spray gun group, rollers, a trolley, a trolley moving motor, a sealed door, a roller mechanism, a roller rotating motor, a trolley bracket, an inspection door and auxiliary machines composition.

[0022] The spray gun group is connected and fixed with the spray gun moving mechanism, the spray gun moving mechanism is installed on the upper part of the main machine, the roller is installed on the roller mechanism, the roller mechanism is installed on the trolley and connected with the roller rotating motor, and the trolley moving motor is installed on the On the trolley, the airtight door is installed on the trolley, and the trolley is placed on the trolley support.

[0023] The mechanism includes: 1. Inspection door 2. Mobile spray gun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com