Single silicon rod transportation trolley for polycrystalline silicon smashing production line

A production line, polysilicon technology, applied in the direction of transportation of passenger cars, transportation and packaging, railway car body parts, etc., can solve the problems of inconvenient removal of polysilicon rods, easy collision of polysilicon rods with baffles, etc., and achieve the effect of avoiding impact and breaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

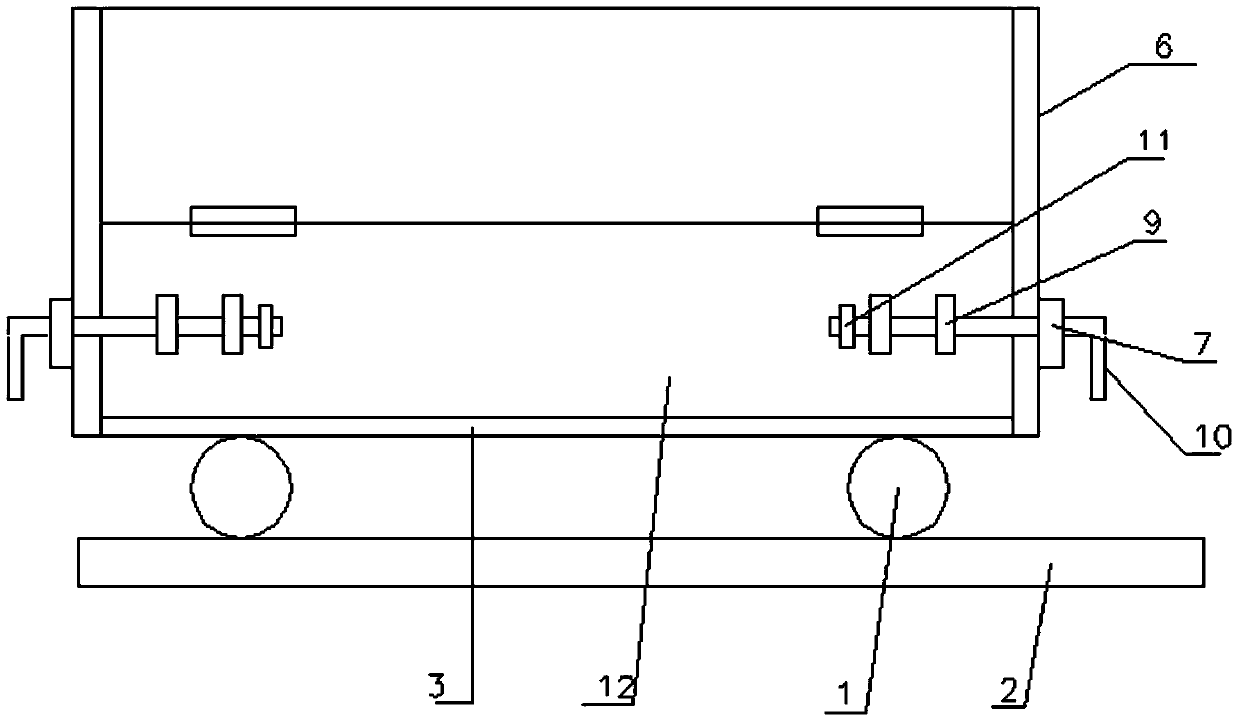

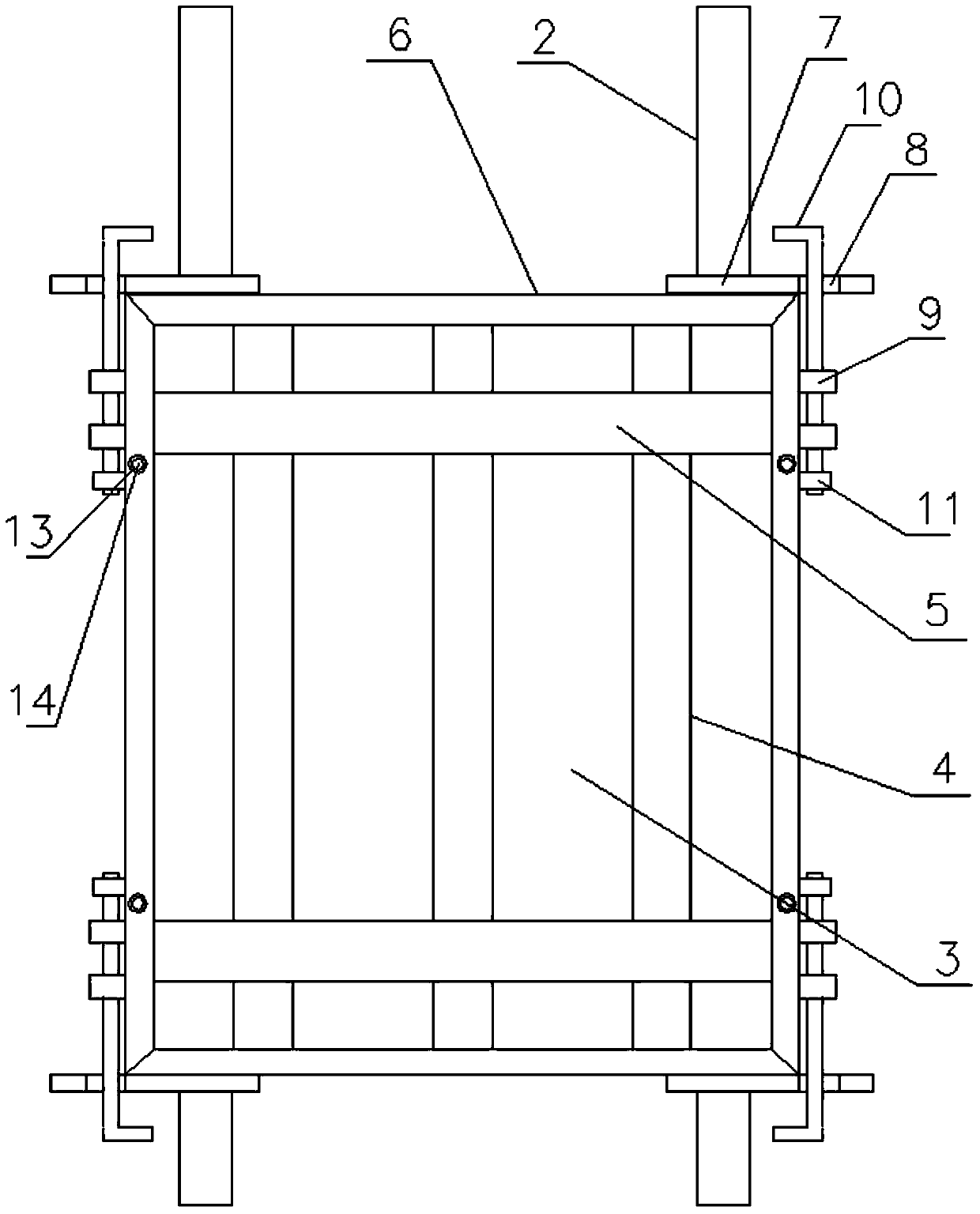

[0014] Such as figure 1 with figure 2 The single silicon ingot transport vehicle of the polysilicon crushing production line shown includes a wheel 1, a rail 2, and a base 3 arranged on the wheel 1. The base 3 is provided with a vertical groove 4 for matching polysilicon rods. The front and rear ends of the groove 4 are provided with transverse grooves 5, and the transverse grooves 5 are deeper than the vertical grooves 4, and four baffle plates 6 are hinged around the base 3, and two baffle plates 6, front and rear, are provided with connecting plates. The plate 7 and the connecting plate 7 are provided with a U-shaped groove 8, wherein the two sides of the left and right baffles 6 are welded with circular rings 9, and two circular rings 9 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com