A method for increasing the service life of a vanadium-containing titanium semi-steel steelmaking converter

A steelmaking converter and furnace age technology, applied in the manufacture of converters, etc., can solve problems such as ash plugging, reduce furnace age, and affect production continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

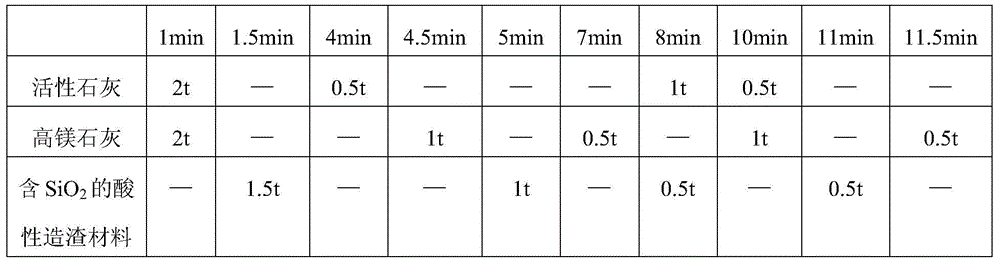

example 1

[0031] Prepare the following materials:

[0032] Semi-steel: 220t; scrap steel: 10t, of which light and thin steel scrap accounts for 30% of the scrap steel; slagging material: 12.5t, of which, active lime 4t, high magnesium lime 5t, containing SiO 2 3.5t of acidic slagging materials.

[0033] 6 minutes before the start of oxygen blowing, 10 tons of steel scrap (among them, 3 tons of light and thin steel scrap) were added to the converter, and 3 minutes before the start of oxygen blowing, 220 tons of semi-steel were poured in. Use an oxygen lance to supply oxygen to the molten steel. The start point of the oxygen supply operation is the timing zero: when the oxygen blowing starts for 60 seconds, the oxygen supply intensity is 1.83m 3 / min·t, the gun position is 2000mm; when the oxygen blowing starts for 60-90 seconds, the oxygen supply intensity is 2.58m 3 / min·t, the gun position is 1700mm; 90s after the start of oxygen blowing, the oxygen supply intensity is 3.5m 3 / min·t...

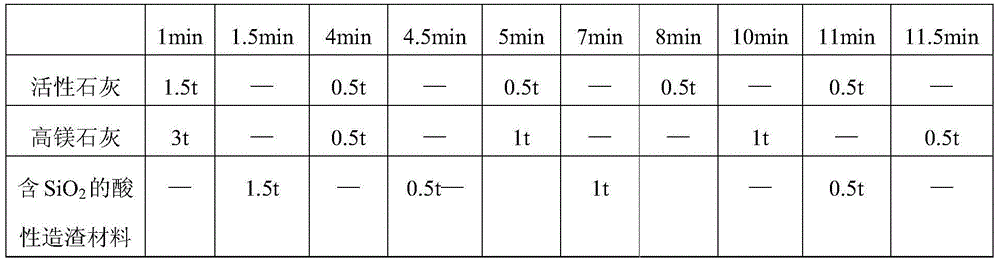

example 2

[0038] Prepare the following materials:

[0039] Semi-steel: 220t; scrap steel: 13t, of which light and thin steel scrap accounts for 45% of the scrap steel; slagging material: 13t, of which, active lime 3.5t, high magnesium lime 6t, containing SiO 2 3.5t of acidic slagging materials.

[0040] 6 minutes before the start of oxygen blowing, 6 tons of steel scrap (including 2.4 tons of light and thin steel scrap) were added to the converter, and 3 minutes before the start of oxygen blowing, 200 tons of semi-steel were poured into it. Use an oxygen lance to supply oxygen to the molten steel. The start point of the oxygen supply operation is the timing zero: when the oxygen blowing starts for 60 seconds, the oxygen supply intensity is 1.92m 3 / min·t, the gun position is 2100mm; when the oxygen blowing starts for 60-90 seconds, the oxygen supply intensity is 2.83m 3 / min·t, the gun position is 1800mm; 90s after the start of oxygen blowing, the oxygen supply intensity is 3.67m 3 / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com