Sintering and pelletizing flue gas multi-pollutant synergistic purification system on basis of bag type dust removal

A bag-type dust removal and purification system technology, applied in gas treatment, chemical instruments and methods, dispersed particle filtration, etc., can solve the problems of blockage and scaling of desulfurization and denitrification equipment, low efficiency of electrostatic dust removal of flue gas, and substandard discharge. Achieve the effect of reducing engineering investment and operating costs, ensuring stable and reliable operation, and avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with this figure.

[0023] A multi-pollutant synergistic purification system for flue gas of a sintering machine or a pelletizing device based on a bag-type dedusting proposed by the present invention can be used for both new projects and renovation projects.

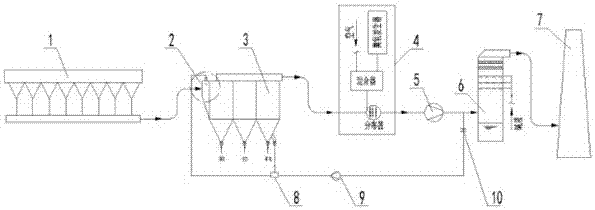

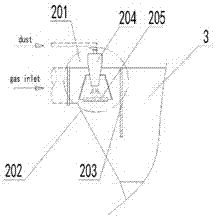

[0024] A multi-pollutant collaborative purification system for sintering machine or pelletizing device flue gas based on bag dust removal, including sintering machine or pelletizing device 1, acid mist eliminator 2, bag filter 3, denitrification reactor 4, induced draft fan 5. Wet desulfurization device 6 and chimney 7 are connected in sequence through steel flue;

[0025] The flue gas of the sintering machine or pelletizing device 1 is first dedusted by the bag filter 3, and then denitrated by the denitrification reactor 4 and desulfurized by the wet desulfurization device 6; in order to eliminate the acid condensation of the flue gas, a The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com