Agate seat of a viscosity machine

A viscosity machine and agate technology, applied in flow characteristics, measuring devices, instruments, etc., can solve problems such as inaccurate measurement, unstable operation of the viscosity machine, and affecting product quality, and achieve correct design, reasonable structure, and meet production needs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

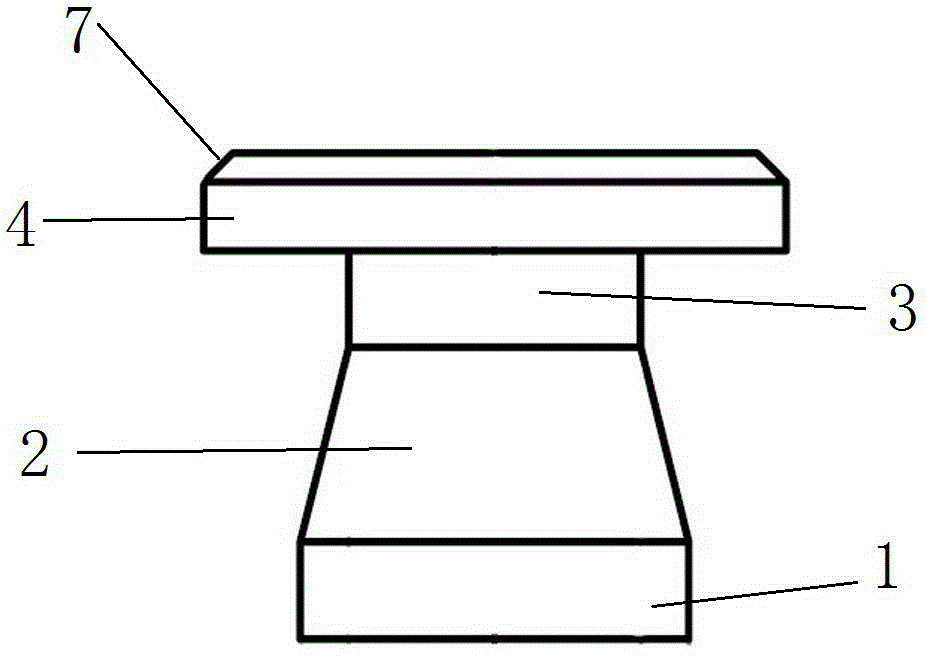

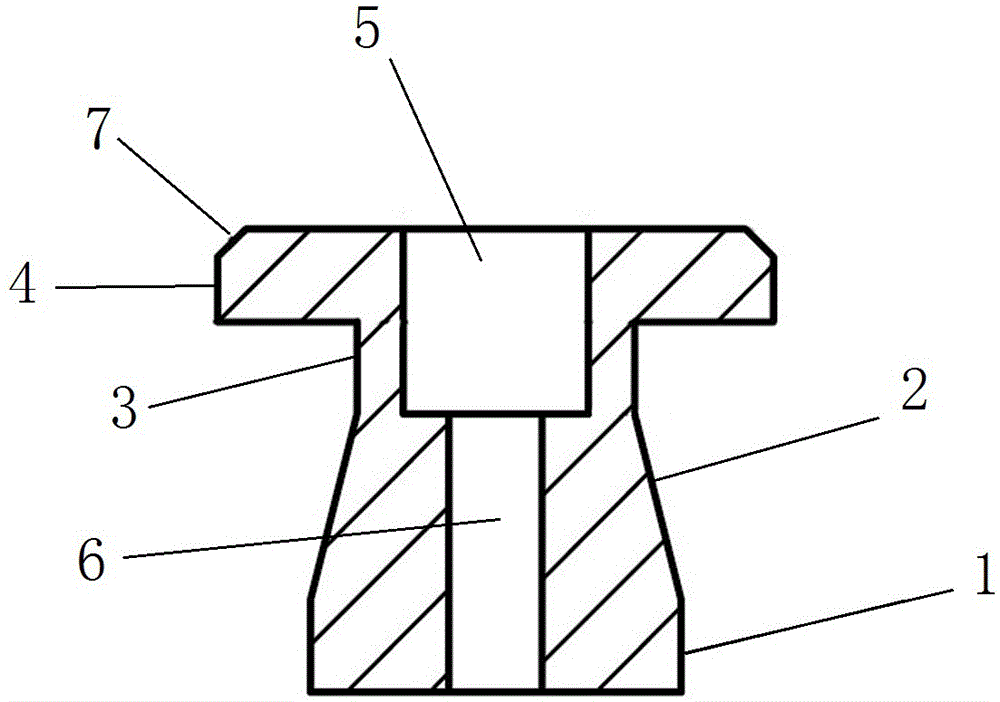

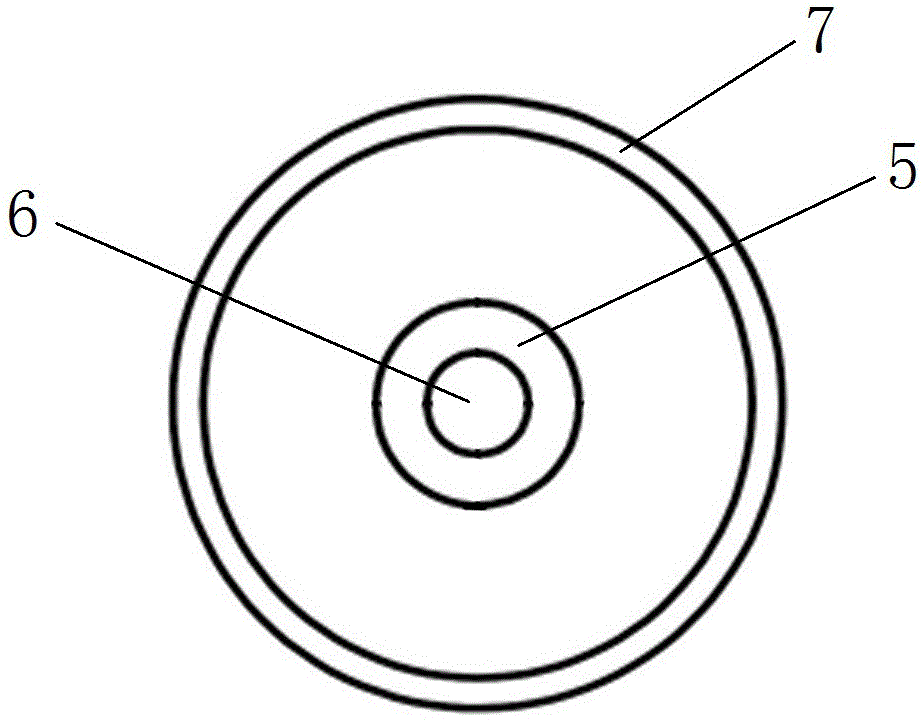

[0009] Describe the present invention in detail below in conjunction with accompanying drawing:

[0010] An agate base for a viscosity machine, comprising a support base, an upper round hole and a lower round hole, characterized in that the agate base is composed of a base 1, a first support base 2, a second support base 3 and a table body 4; the base 1 is a cylinder, the diameter of the outer surface of the base 1 is 40mm, and the height of the upper and lower sides of the base 1 is 10mm; The diameter of the upper circular surface of 2 is 30mm, the diameter of the lower circular surface of the first support seat 2 is 40mm, and the upper and lower heights of the first support seat 2 are 30mm; the lower circular surface of the first support seat 2 and the base 1 The upper circular surface of the first support seat 2 is mixed and connected, the center of the first support seat 2 is on the same axis as the center of the base 1; the second support seat 3 is located above the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com