Multi-chip packaging body and packaging method

A multi-chip packaging and packaging method technology, which is applied in the fields of electric solid-state devices, semiconductor devices, semiconductor/solid-state device manufacturing, etc., can solve the problems of small number of chips, single function, and inability to meet the new needs of the electronic market, so as to save space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

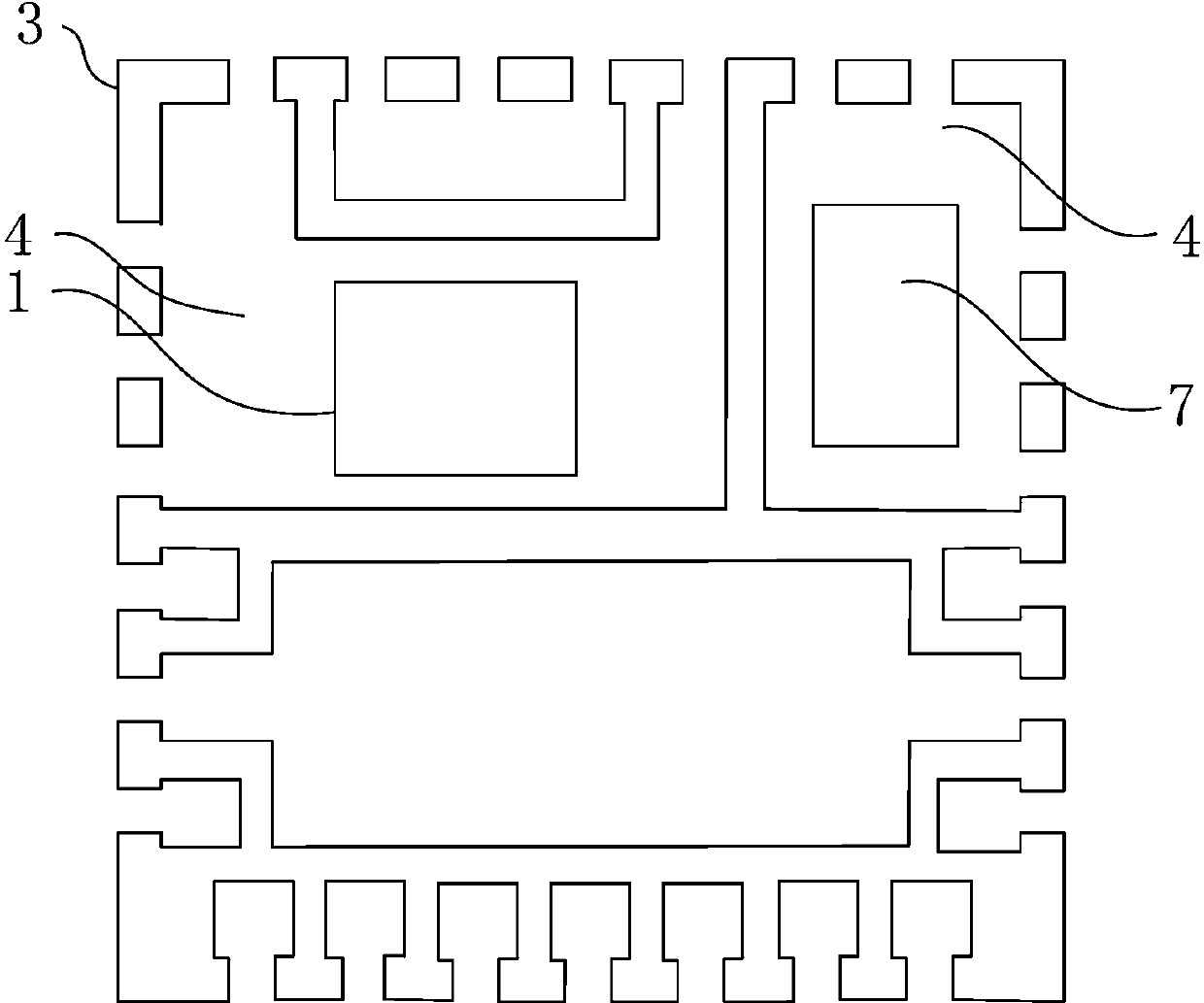

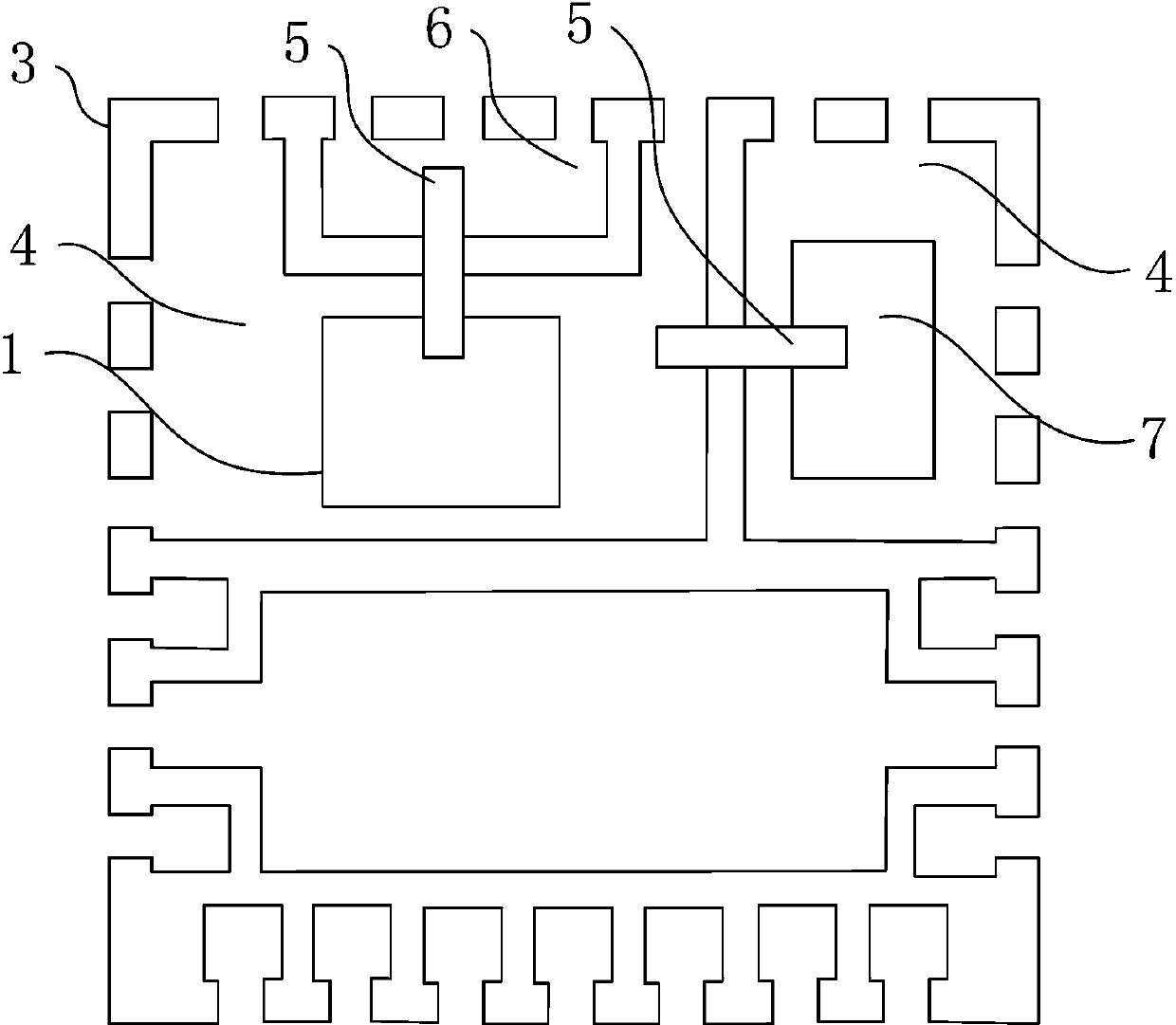

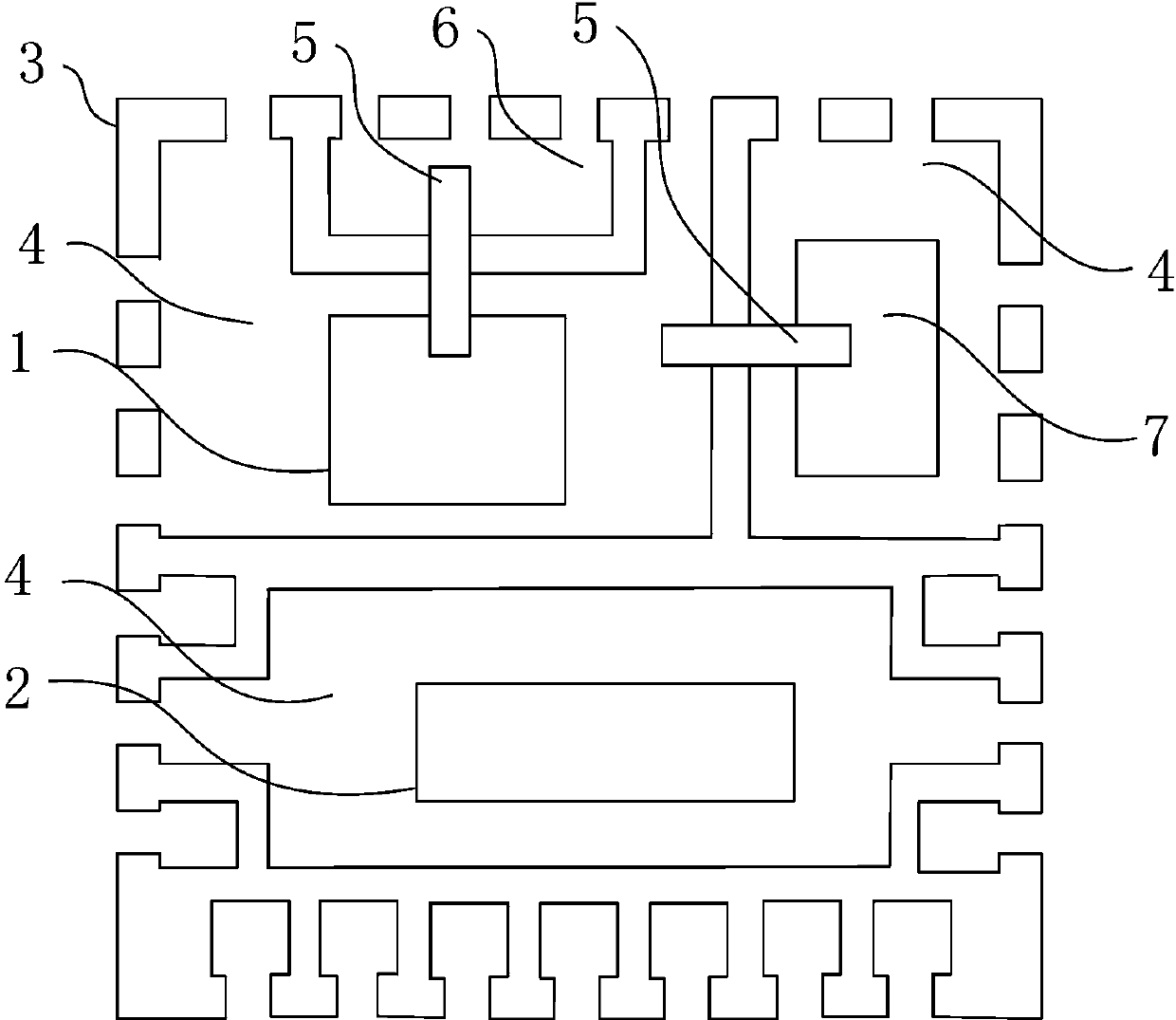

[0024] The specific implementation of the multi-chip package and its packaging method provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0025] figure 1 Shown is the flow chart of the packaging method of the multi-chip package of the present invention, see figure 1 , the packaging method includes the following steps: step S10, using tin powder solder to weld the first functional chip on the chip base of the lead frame; step S11, using chip bonding wire to bond the first functional chip to the pins of the lead Connecting, the chip bonding wire is welded with the electrode of the first functional chip and the pin of the lead frame with tin powder solder; step S12, heating the lead frame for the first time to solidify the tin powder solder; step S13, welding the controller chip on the chip base of the lead frame with a welding adhesive; step S14, heating the lead frame for the second time to cure the welding adhesiv...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap