A Miniaturized Temperature and Stress Controllable Magnetoelectric Transducer

A magnetoelectric transducer, stress technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., can solve the problem of limited use range, temperature control and force control Inconvenient, complex devices and other problems, to achieve the effect of magnetoelectric conversion capability, strong magnetoelectric coupling strength, and increase or decrease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

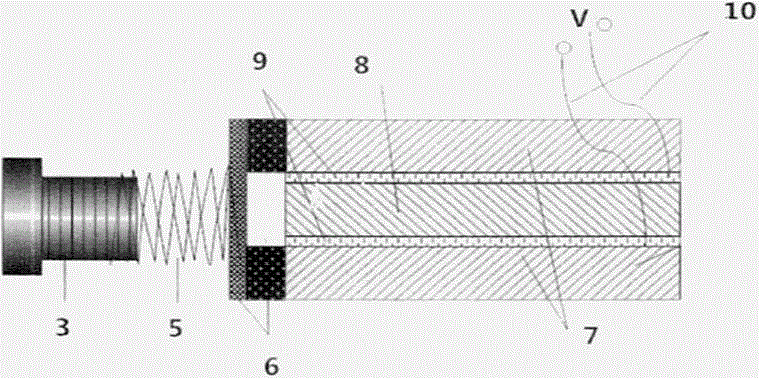

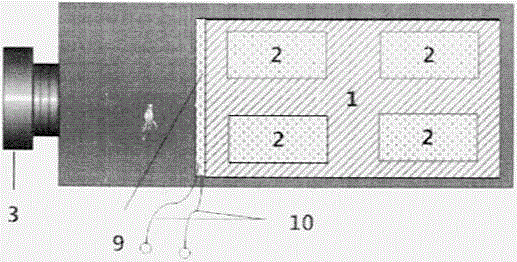

[0035] The miniaturized temperature and stress controllable magnetoelectric transducer of the present invention comprises: magnetoelectric composite structure 1, encapsulation shell 4 that antimagnetic material is made, antimagnetic screw 3, antimagnetic piston 6 and place on the upper surface of magnetoelectric composite structure 1 A plurality of semiconductor temperature control sheets 2; the magnetoelectric composite structure 1 is a laminated composite structure formed by laminating and bonding two sheets of giant magnetostrictive material 7 and a piece of piezoelectric material 8. The piezoelectric material 8 is a PZT material, super The magnetostrictive material 7 is a Terfenol-D material, which is rectangular in shape, and the layers are bonded by epoxy resin, and the magnetoelectric composite structure 1 is fixed on the bottom surface of the package shell 4 by epoxy resin; the package shell 4 There is an opening on one side surface and an antimagnetic screw 3 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com