Tower-shaped supporting structure

A supporting structure and tower-shaped technology, applied in the direction of structural elements, towers, installation/supporting configuration of wind turbines, etc., can solve problems such as difficult automation, achieve the effect of improving occupational safety and reducing lateral tension reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

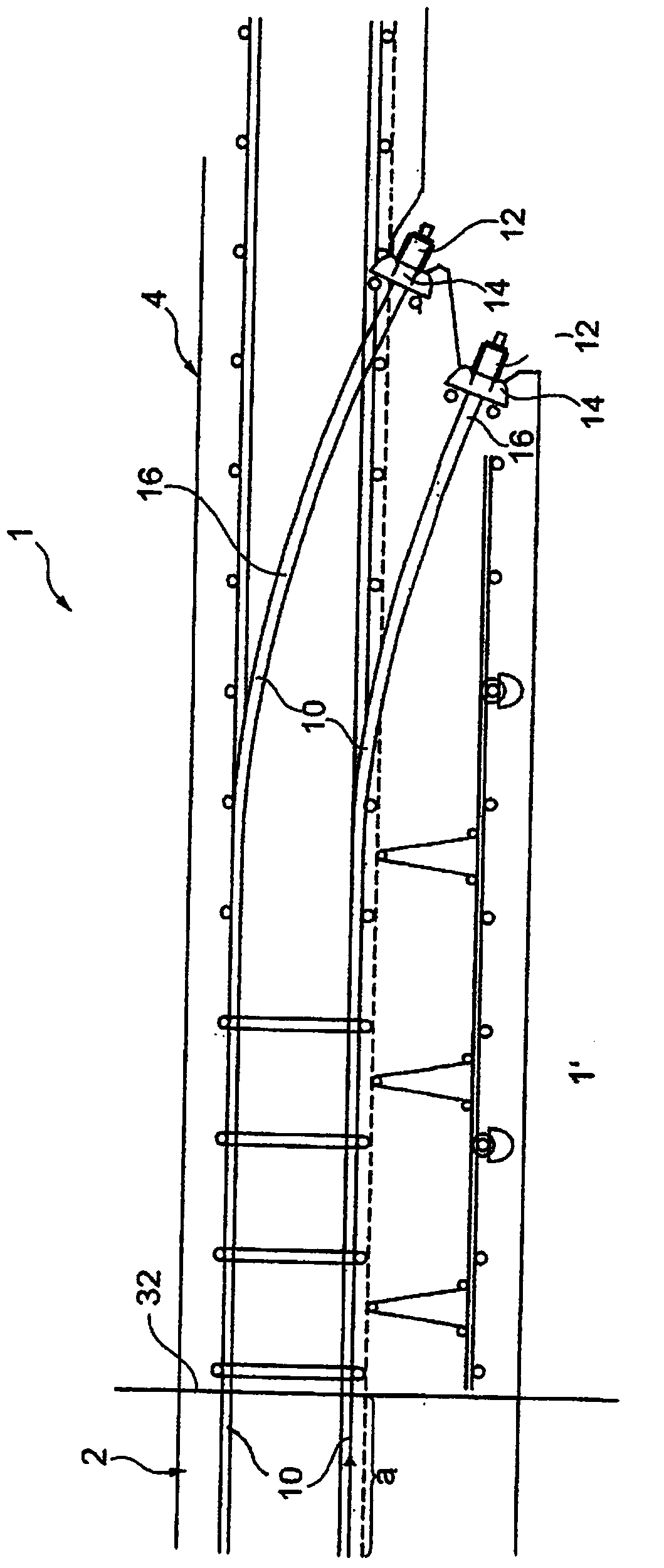

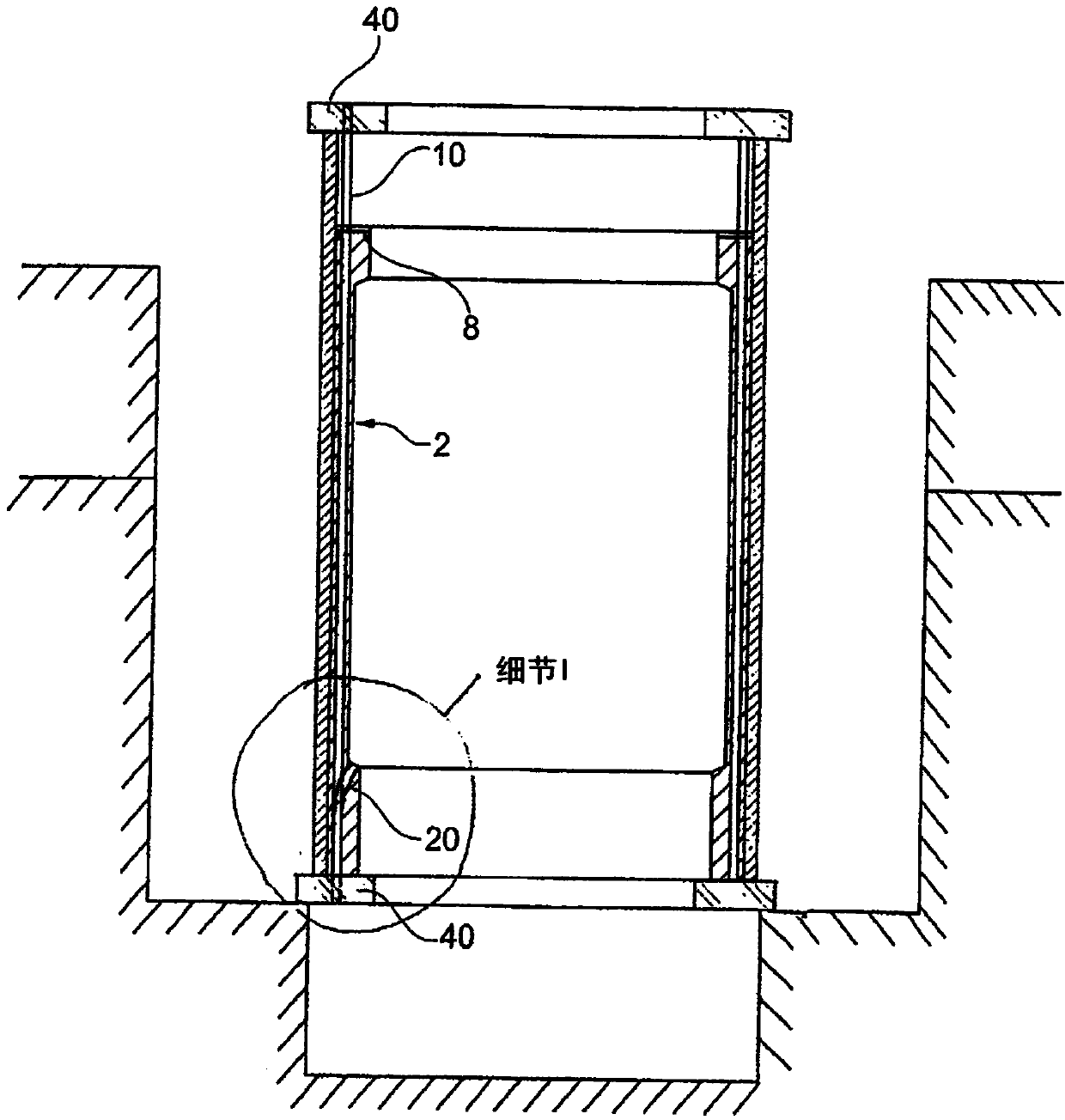

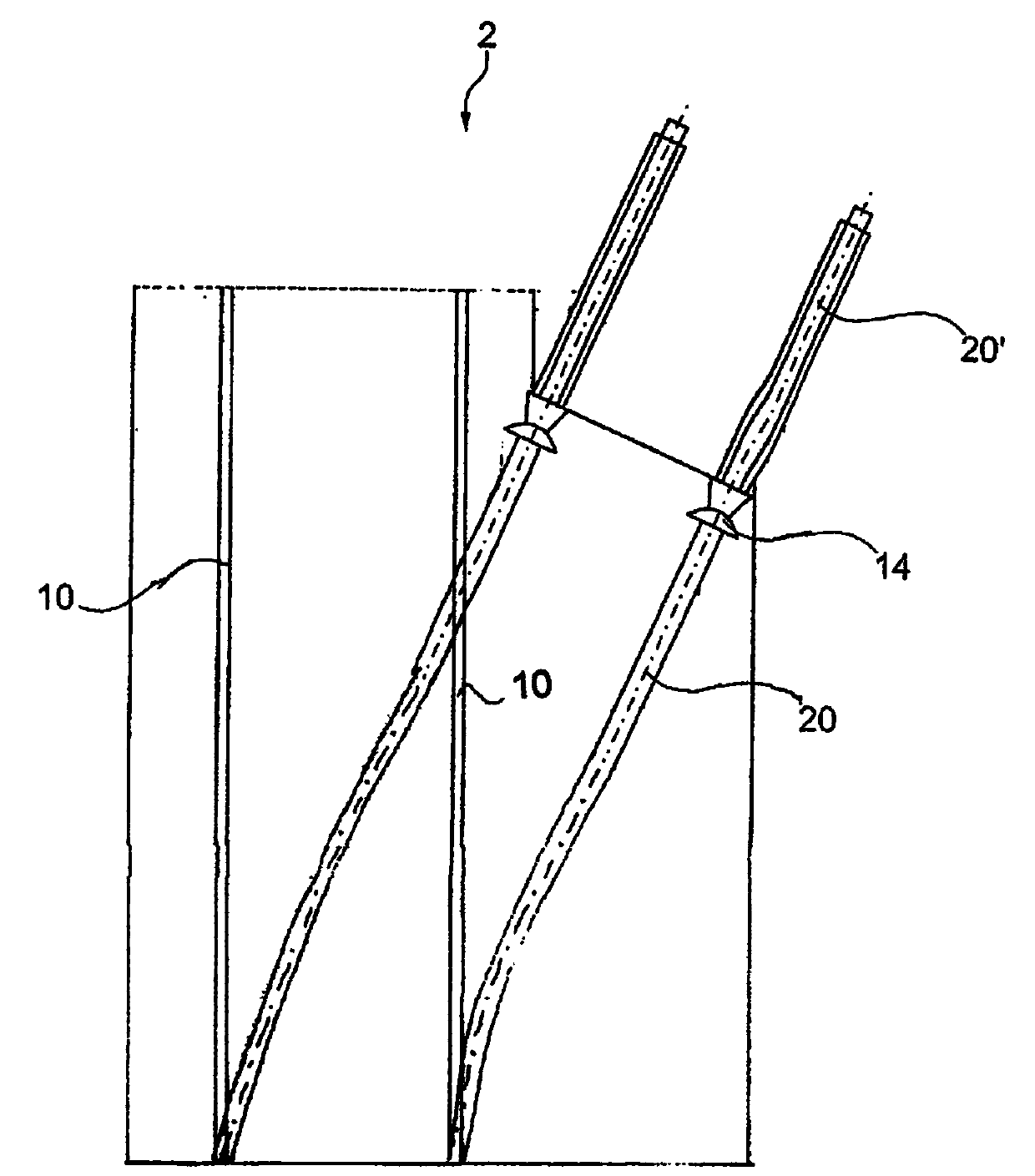

[0032] figure 1 A partial sectional view of a tower-shaped support structure 1 according to the invention is schematically shown. The tower support structure may serve various purposes within the scope of the present invention, and is also used, for example, as a support structure for wind farms. The tower-shaped support structure 1 is built by stacking and fastening together a plurality of prestressed concrete elements 2, 4, wherein each of the prestressed concrete elements 2, 4 comprises a plurality of tension cables or strands An elongated prestressing device 10 in the form of as from figure 1 It can be seen that the prestressing device 10 of the prestressed concrete part 2 is on the upper side of the part ( figure 1 center on the right) protrudes beyond the element and is guided into the adjacent prestressed concrete element 4 and is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com