Base film for dicing sheet and dicing sheet

A technology of substrate film and cutting sheet, which is used in film/sheet adhesive, transportation and packaging, non-polymer adhesive additives, etc. problem, to achieve the effect of reducing cutting chips and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

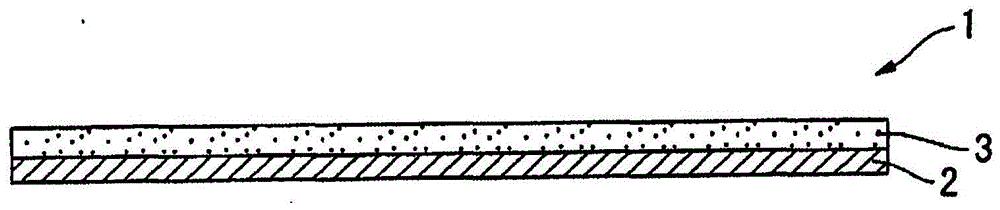

Image

Examples

Embodiment 1

[0119] (1) Production of substrate film

[0120] The tensile modulus at 23° C. of a cycloolefin copolymer (manufactured by Polyplastics Co., Ltd., product name TOPAS (registered trademark) 8007) which is a thermoplastic resin containing an aliphatic ring-containing resin (a1) (based on the test example described later) The results obtained in 1, the same below): 2.0 GPa, the fluidization temperature (based on the results obtained in Test Example 2 described later, the same below): 142° C.) 5.0 parts by mass, which is as low as the non-cyclic olefin resin (a2) Density polyethylene (manufactured by Sumitomo Chemical Co., Ltd., product name Sumikasen (registered trademark) L705, tensile modulus at 23°C: 140 MPa) 95.0 parts by mass, using a twin-screw kneader (manufactured by Toyo Seiki Seisakusho Co., Ltd. ) was melt-kneaded at 210°C to obtain an extrusion raw material for the resin layer (A). This raw material was extruded through a small T-die extruder (Toyo Seiki Seisakusho C...

Embodiment 2

[0125] Dicing sheets were produced in the same manner as in Example 1, except that the content of the ring-containing resin (a1) in Example 1 was changed to 30.0 parts by mass and the content of the acyclic olefin-based resin (a2) was changed to 70.0 parts by mass. The internal haze value of the obtained resin layer (A) was 29.8%.

Embodiment 3

[0127] Dicing sheets were produced in the same manner as in Example 1, except that the content of the ring-containing resin (a1) in Example 1 was changed to 50.0 parts by mass and the content of the acyclic olefin-based resin (a2) was changed to 50.0 parts by mass. The internal haze value of the obtained resin layer (A) was 47.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com