Vanadium-base SCR (selective catalytic reduction) catalyst for efficiently treating nitric oxides in diesel engine exhaust and preparation method thereof

A technology of SCR catalyst and nitrogen oxide, which is applied in the field of new vanadium-based SCR catalyst and its preparation, can solve the problems of poor thermal stability at high temperature, achieve the effects of improving low-temperature performance, widening the working temperature range, and improving high-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Preparation of monolithic ErVO 4 / TWS / cordierite honeycomb ceramic catalyst E1 in aged state at 650°C:

[0034] 400 cells per square inch (cpsi) cordierite honeycomb ceramics (produced by NGK, Japan) were used as the loaded ceramics. First cut the cordierite honeycomb ceramics into small cylinders with a size of Φ13×60 (mm) for later use.

[0035] The preparation method of the vanadium-based SCR catalyst for efficiently treating nitrogen oxides in diesel engine exhaust, the steps are as follows in parts by weight:

[0036] (1) Preparation of vanadium-erbium-iron complex: first mix 3 parts of NH 4 VO 3Add 15 parts of deionized water to the powder and dissolve it in a water bath at 80°C to obtain solution a;

[0037] Dilute ferric nitrate and erbium nitrate by Fe X The form of Ery mixed with Fe X In Ery, x is the molar ratio of iron, which is 0, and y is the molar ratio of erbium, which ranges from 0 to 1. Solution b is obtained after fully mixing;

[003...

Embodiment 2

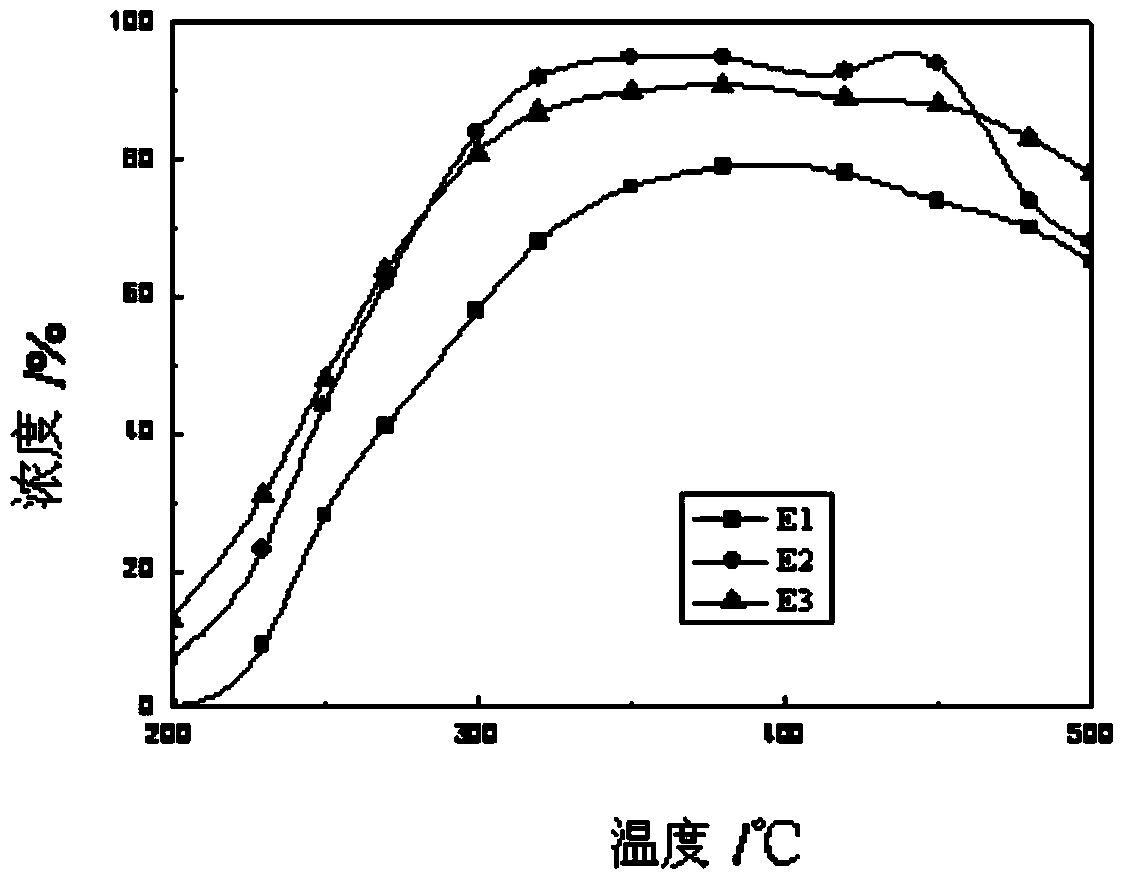

[0048] Preparation of monolithic ErVO 4 / TWS / cordierite honeycomb ceramics 700°C aged catalyst E2: The specific preparation method, aging conditions and evaluation conditions are basically the same as E1, the difference is that the catalyst made during aging is aged at 700°C for 10 hours, and the test results of the aged catalyst activity are shown in figure 1 .

Embodiment 3

[0050] Preparation of monolithic ErVO 4 / TWS / cordierite honeycomb ceramics 750°C aged catalyst E3: The specific preparation method, aging conditions and evaluation conditions are basically the same as E1, the difference is that the catalyst made during aging is aged at 750°C for 10 hours, and the test results of the aged catalyst activity are shown in figure 1 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap