Riveting square jig metal pin positioning mechanism

A positioning mechanism and riveting quartet technology, applied in the direction of manufacturing tools, metal processing equipment, auxiliary devices, etc., can solve problems such as affecting the riveting effect and dislocation of riveting parts, and achieve the effect of improving quality and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

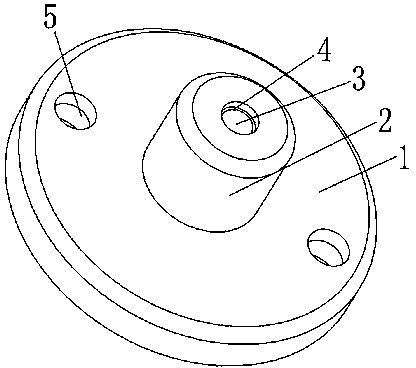

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as figure 2 As shown, a gold pin positioning mechanism for a riveted square jig includes a circular base 1 and a cylindrical positioning part 2. A cylindrical positioning part 2 is arranged on the top of the circular base 1. From the top of the cylindrical positioning part 2 to the circular The bottom of the base 1 is provided with a through hole 3 , and a circle of limiting plate 4 is arranged in the hole 3 of the cylindrical positioning part 2 . The length of the cylindrical positioning column 2 is greater than twice the thickness of the circular base 1 . Two positioning holes 5 are arranged on the circular base 1 . The center of the opening 3 of the cylindrical positioning part 2 and the centers of the two positioning holes 5 are located on the same straight line.

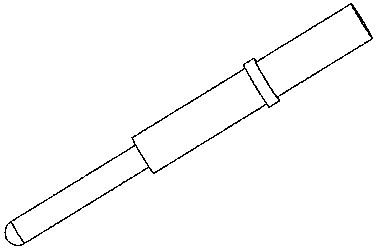

[0014] The gold needle positioning mechanism of the riveting square jig of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com