Oblique core-pulling mechanism of injection mold

An oblique core-pulling and injection mold technology, applied in the field of side core-pulling mechanisms, can solve the problems of very high injection molding production conditions, increased equipment costs, and large injection mold structure, and achieves reduced injection molding production conditions requirements, low cost, Simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

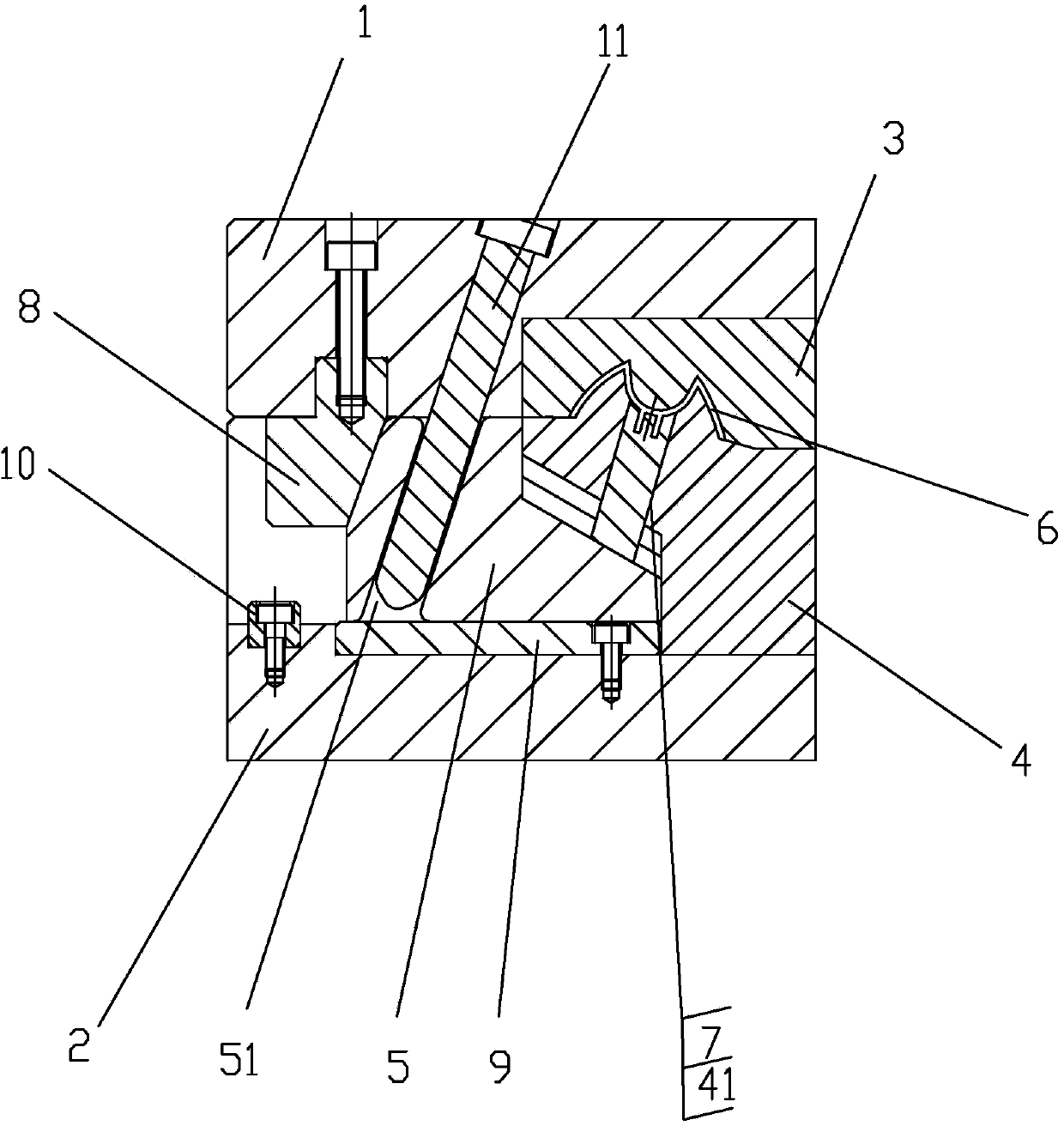

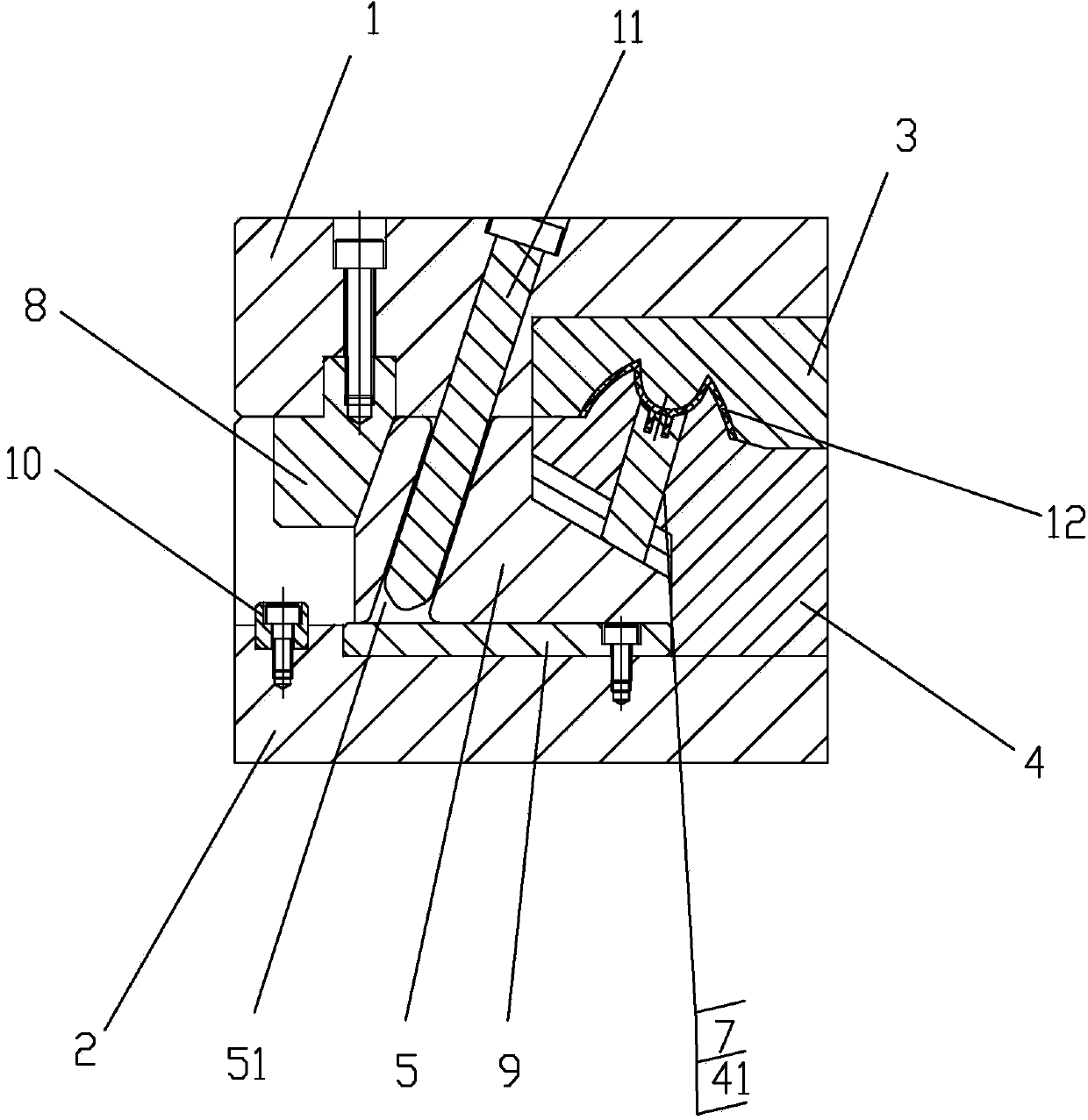

[0014] An injection mold oblique core-pulling mechanism, comprising an upper template 1 and a lower template 2 capable of opening and closing with the upper template 1, the upper template 1 is provided with an upper mold insert 3, and the lower template 2 is provided with a lower mold insert 4, and a slider 5 that can slide left and right relative to the two when they are opened and closed is provided between the upper template 1 and the lower template 2, and the lower mold insert There is an inclined chute 41 on the piece 4, and the chute 41 is provided with a sliding block that can move with the slider 5 and is surrounded by the lower mold insert 4 and the upper mold insert 3. The movable core 7 of the plastic part molding cavity 6 is provided with a wedging block 8 that can wedge the slider 5 tightly when it fits with the lower template 2 on the upper template 1 . Durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com