Roving spindle trolley

A trolley and spindle technology, which is applied in the field of roving spindle trolleys, can solve the problems of inconvenient turning and turning, and achieve the effects of simple structure, light and flexible operation, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

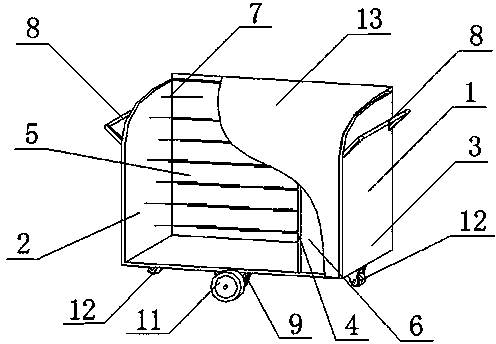

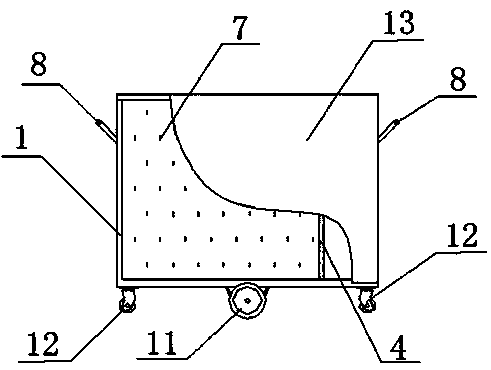

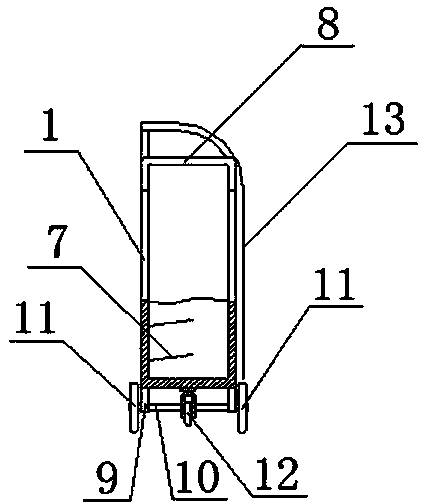

[0010] combine figure 1 , figure 2 and image 3 As can be seen, the vehicle body 1 of the roving spindle trolley of the present invention is a semi-open rectangular box body without a top plate and a side plate. A partition plate 4 parallel to the front side panel 2 and the rear side panel 3 is provided inside the vehicle body 1, and the partition plate 4 divides the interior space of the vehicle body 1 into a roving spindle storage area 5 and a roving bobbin storage area 6, generally Under the circumstances, the roving spindle holding area 5 is larger, and the roving bobbin holding area 6 is smaller, and the roving bobbins can be directly placed on the roving bobbin holding area 6 . On the inner wall of the side plate of the roving spindle holding area 5, there are roving spindle hanging rods 7 arranged evenly and evenly in a staggered manner up and down. The roving spindles are inserted and hung on the roving spindles hanging rod 7 in an orderly manner, which avoids the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com