an air flotation device

A technology of air flotation and dissolved air water, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problems of inability to flotation fine particles, increase equipment investment, and affect water collection and other problems, to achieve the effect of reducing the amount of air bubbles, increasing energy consumption, and improving the treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

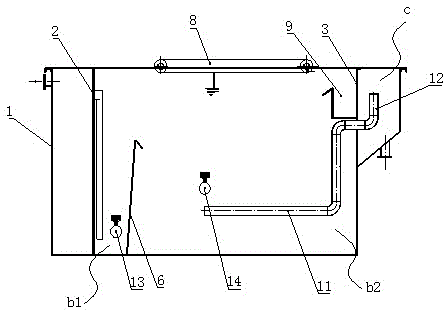

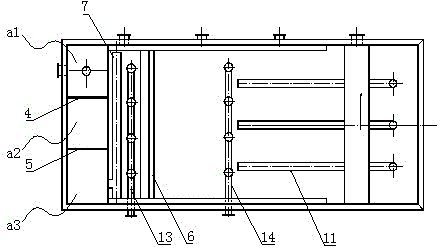

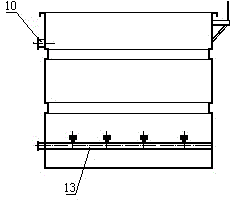

[0010] Such as figure 1 , 2 , 3, including box 1, first partition 2, second partition 3, third partition 4, fourth partition 5, flashing plate 6, water distribution pipe 7, slag scraper 8, slag collector Groove 9 , slag outlet 10 , water collecting pipe 11 , water outlet pipe 12 , first dissolved air water release pipe 13 and second dissolved air water release pipe 14 .

[0011] A box body 1, which is divided into a pretreatment area, an air flotation water collection area and a clean water area by the first partition board 2 and the second partition board 3 from front to back; the first partition board, the second partition board and the The casing is of the same height; the pretreatment area is divided into anaerobic zone a1, aerobic zone a2 and sedimentation zone a3 by the third partition 4 and the fourth partition 5; the third partition 4, the fourth partition 5 and the box Body 1 is of the same height; the air flotation catchment area is provided with a flashing plate 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com