Cloth cutting machine

A cutting machine and cloth technology, which is used in textiles, papermaking, and textile material cutting, etc., can solve the problems of insufficient smoothness, waste, and labor-saving on the edges of the cloths, and achieve the effects of smooth and intact edges of the cloths, easy to use, and convenient to replace the cloths.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

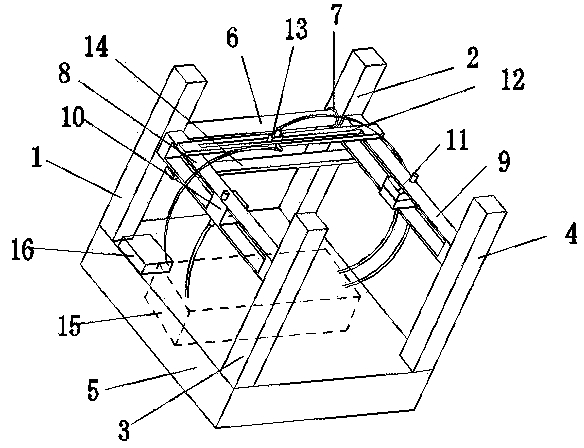

[0019] Embodiment: a cloth cutting machine, comprising a base 5, a cross bar 6, a first support 1, a second support 2, a third support 3 and a fourth support 4, the first, second, third and fourth supports 1, 2, 3, 4 are respectively fixed on the four corners of the base 5, the cloth is sleeved on the cross bar 6, the first and second brackets 1, 2 are provided with positioning grooves 7, and the cross bar 6 is disassembled. It is fixed in the positioning groove 7; when the cloth needs to be replaced, the cross bar 6 is removed from the positioning groove 7, and then the cross bar 2 is inserted into the cloth that needs to be used, which is very convenient.

[0020] It also includes a first slide rail 8 and a second slide rail 9, one end of the first slide rail 8 is fixed on the first support 1, and the other end of the first slide rail 8 is fixed on the third support 6, so One end of the second slide rail 9 is fixed on the second support 5, and the other end of the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com