Cloth roll taking and changing mechanism

A technology of cloth rolls and pallets, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of low efficiency, troublesome operation, and placing the cloth roll mandrel in place, so as to save manpower and material resources, High efficiency, easy replacement of cloth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

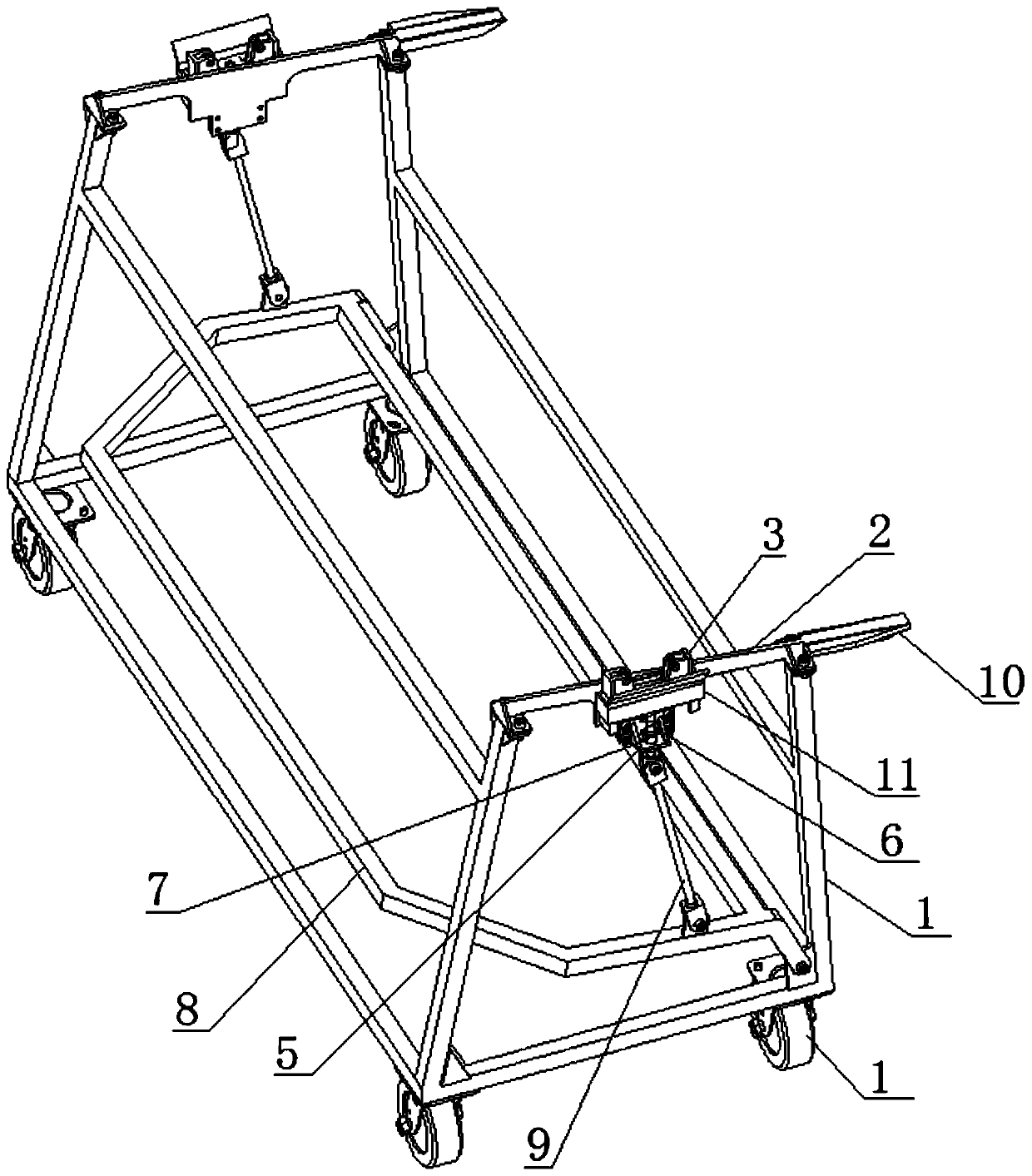

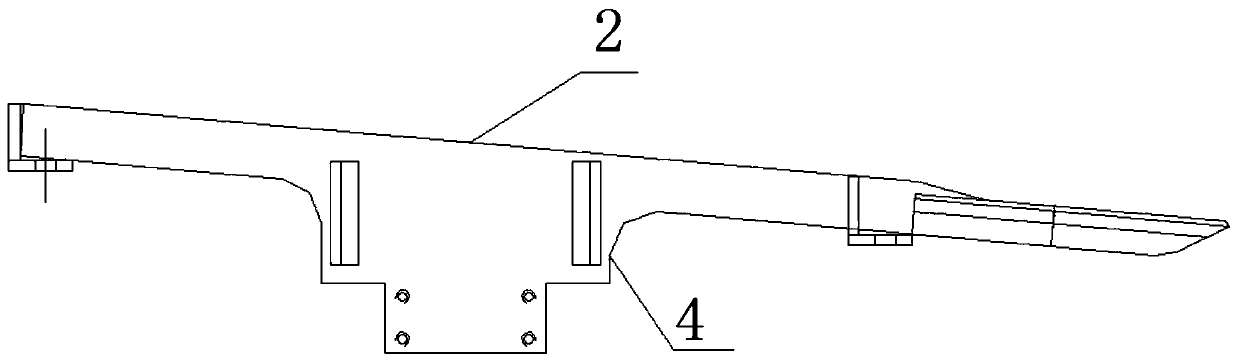

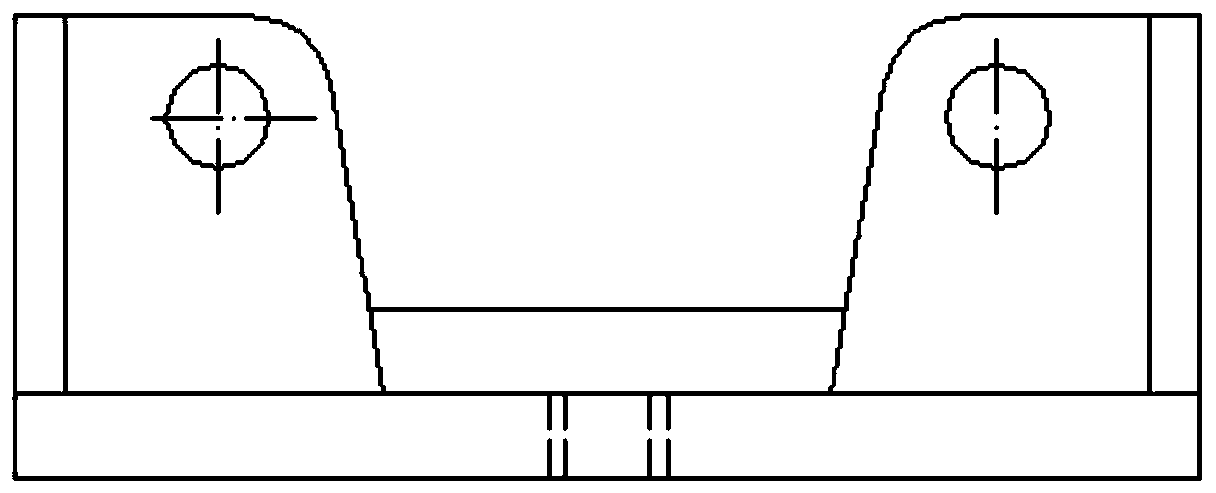

[0017] a kind of like Figure 1-3 The cloth roll taking and changing mechanism shown includes a vehicle frame 1, which has two supporting surfaces, front and rear, wherein the height of the rear supporting surface is higher than that of the front supporting surface. The top of the vehicle frame 1 has a supporting plate 2 connected from the rear supporting surface to the front supporting surface, the number of the supporting plates 2 is two, and they are respectively located at both ends of the top of the vehicle frame 1 . The two supporting plates 2 are arranged in parallel, and each of the supporting plates 2 is inclined from the rear supporting surface to the front supporting surface. Under the action, it will automatically roll along the supporting plate 2. The middle part of the supporting plate 2 is provided with a vertically movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com