A high-efficiency energy-saving environmental protection filter

A high-efficiency, energy-saving, filter technology, applied in the field of beneficiation, can solve the problems of low production qualification rate, unfriendly environment, and high maintenance costs, and achieve the effects of reliable performance, simple manufacturing, and improved motor utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

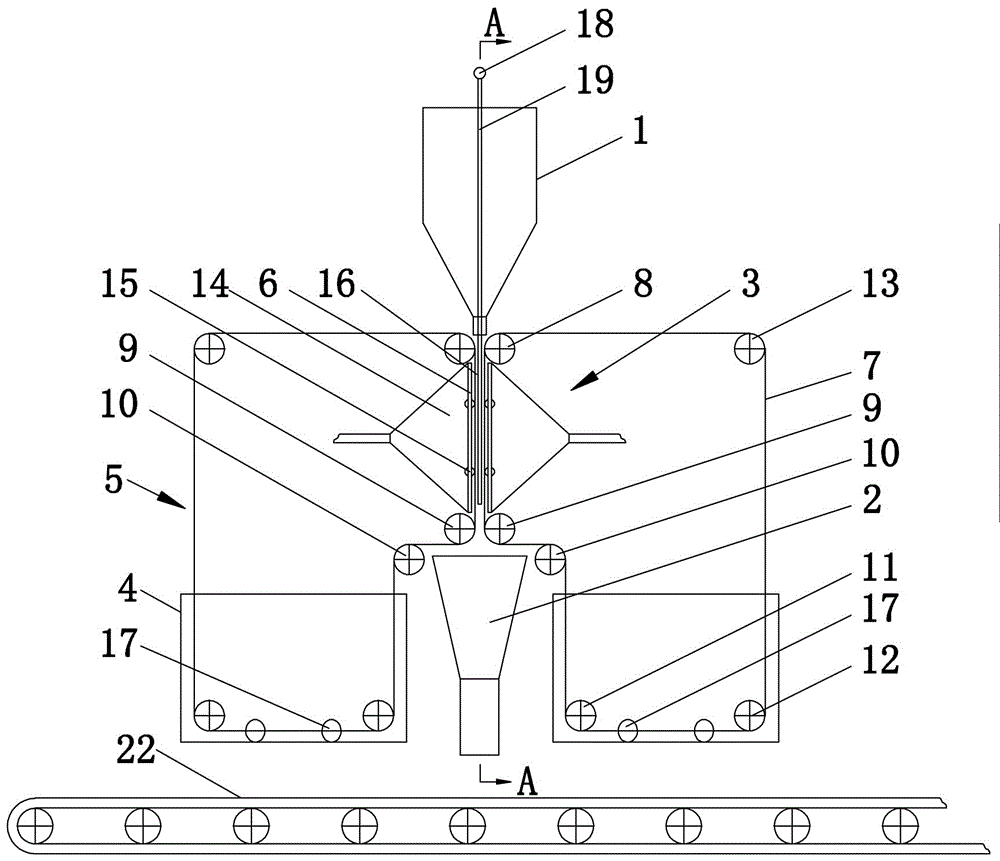

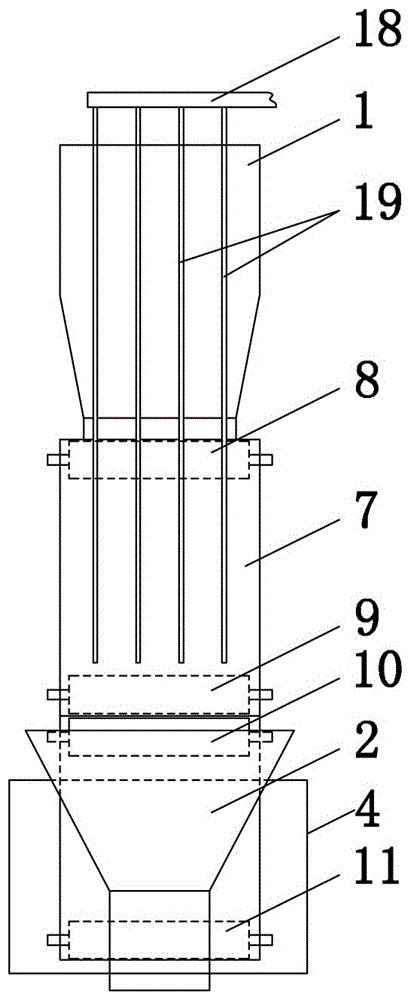

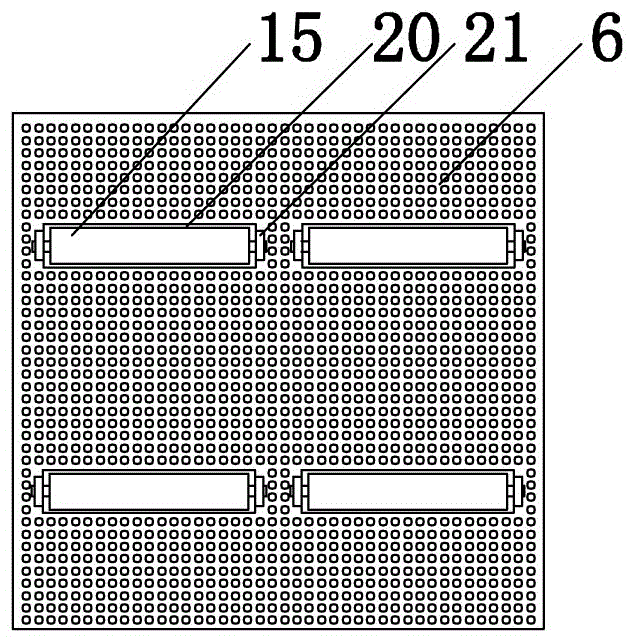

[0034] The specific solution of this embodiment is: a high-efficiency energy-saving and environmental protection filter, which has a feed hopper 1 and a discharge hopper 2, especially: the feed hopper 1 is located directly above the discharge hopper 2, and the feed hopper 1 and discharge hopper Two groups of vacuum filter devices 3 are symmetrically arranged on both sides of the central axis of 2, and a filter cloth cleaning pool 4 is provided on both sides of the discharge hopper 2. The vacuum filter device 3 includes a filter cloth circulation walking mechanism 5, a filter support plate 6 and Vacuum negative pressure device; the filter cloth circulation walking mechanism 5 includes a filter cloth support wheel assembly and a filter cloth 7, the upper fixed wheel 8 of the filter cloth support wheel assembly is located at the outlet end of the feed hopper 1, and the lower fixed wheel 9 is located at the outlet hopper 2 The entrance end of the lower fixed wheel 9 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com