Device and method for dismantling offshore pile pipe through reversed pulling under pressure

A pile pipe and pressure technology, which is applied in the field of offshore pile pipe pressure back-pull removal device, can solve the problems of large adaptability of work equipment, high operation risk of operators, and complicated operation process, so as to achieve low cost and high operation safety , suitable for a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

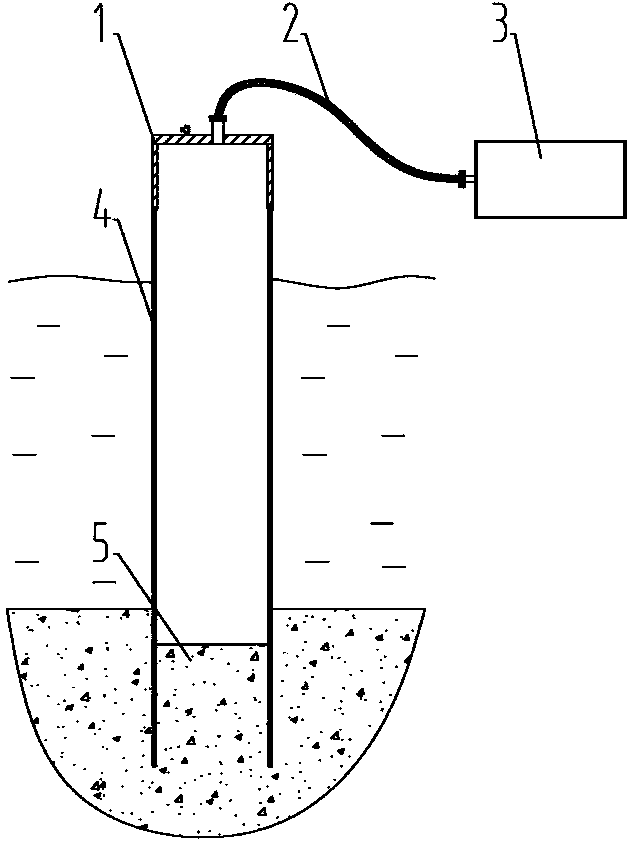

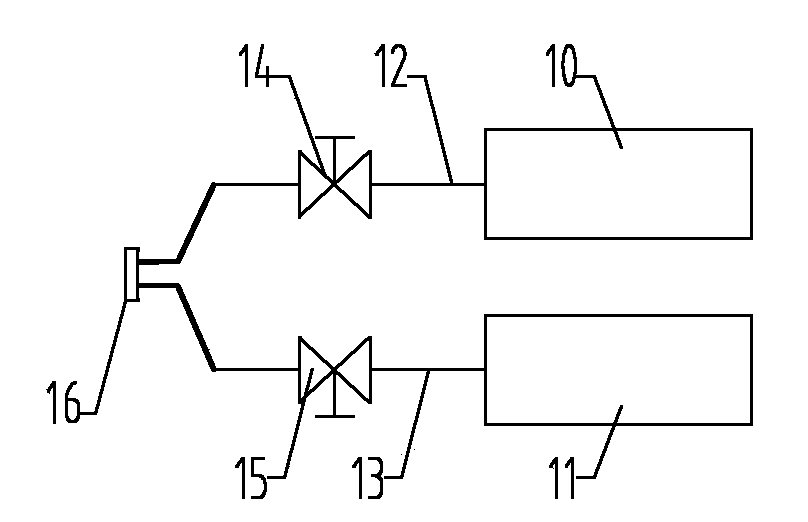

[0012] Such as figure 1 , figure 2 , image 3 As shown, the offshore pile pipe pressure reverse pullout device includes: pile pipe pressure head 1, high-pressure pipe 2, high-pressure injection device 3; pile pipe pressure head 1, high-pressure injection device 3 are connected through high-pressure pipe 2; The pipe pressure head 1, the high-pressure pipe 2, the high-pressure injection device 3, the pile pipe to be removed 4, and the soil at the bottom of the pile 5 constitute a high-pressure reverse pullout system.

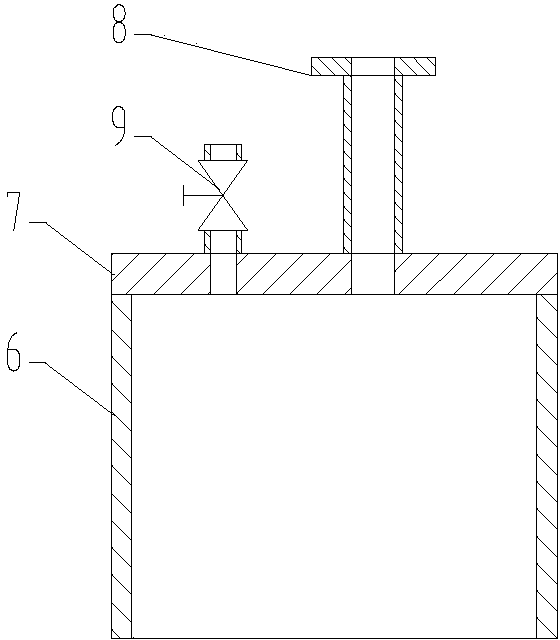

[0013] Pile pipe pressure-bearing head 1, including: head cylinder 6, sealing plate 7, first high-pressure pipe connection joint 8 and exhaust valve 9; one end of the head cylinder 6 is open, the other end is provided with a sealing plate 7, the head The cross-section of the open end of the cylinder body 6 is the same as the cross-section shape of the pile pipe 4 to be removed. The sealing plate 7 is sealed and connected with the head cylinder body 6. The seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com