Hazardous solid waste pretreatment device

A pretreatment device, waste solid technology, applied in transportation and packaging, solid waste removal, chemical instruments and methods, etc., can solve problems affecting treatment efficiency, large limitations, single treatment line, etc. Prevent dangerous effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

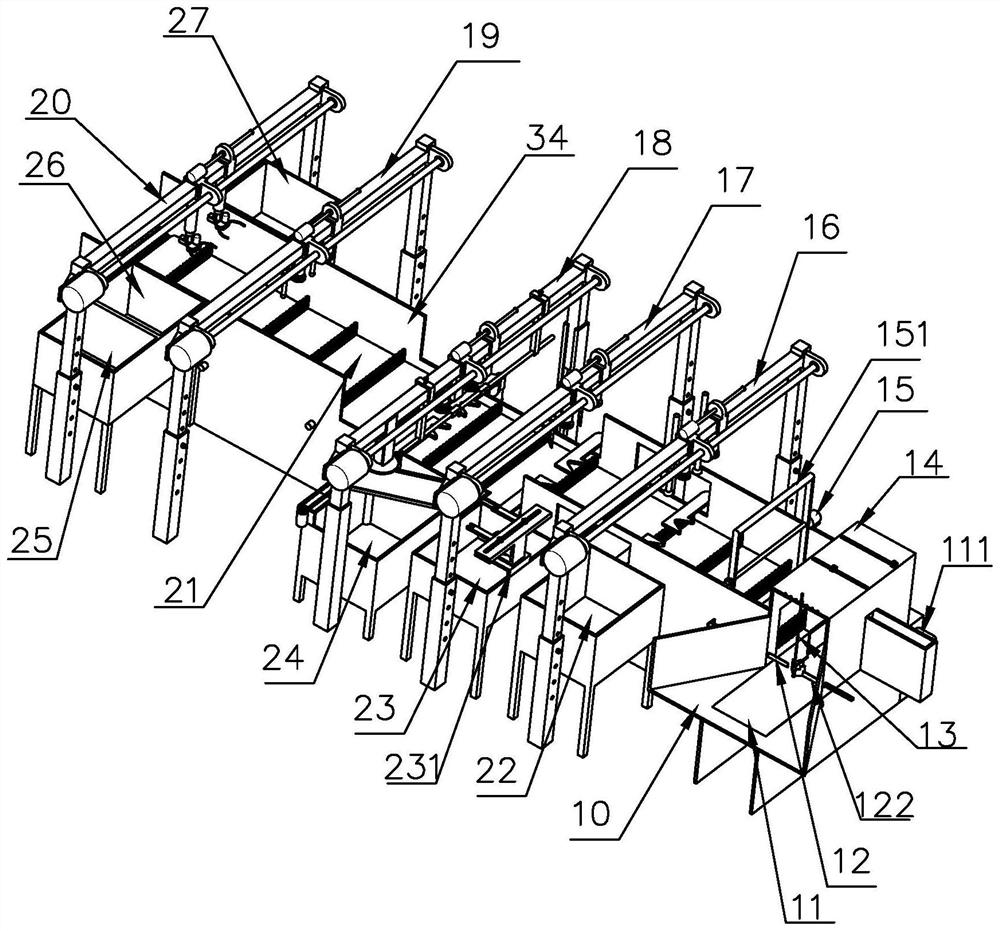

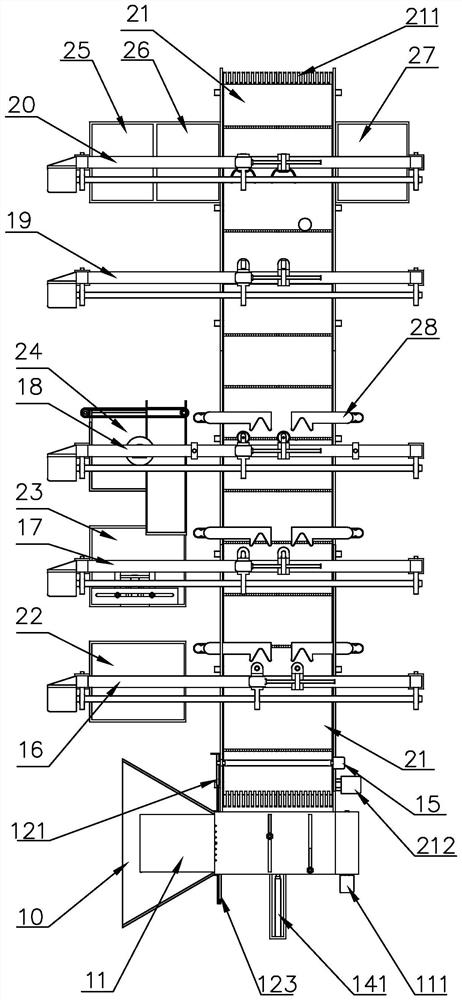

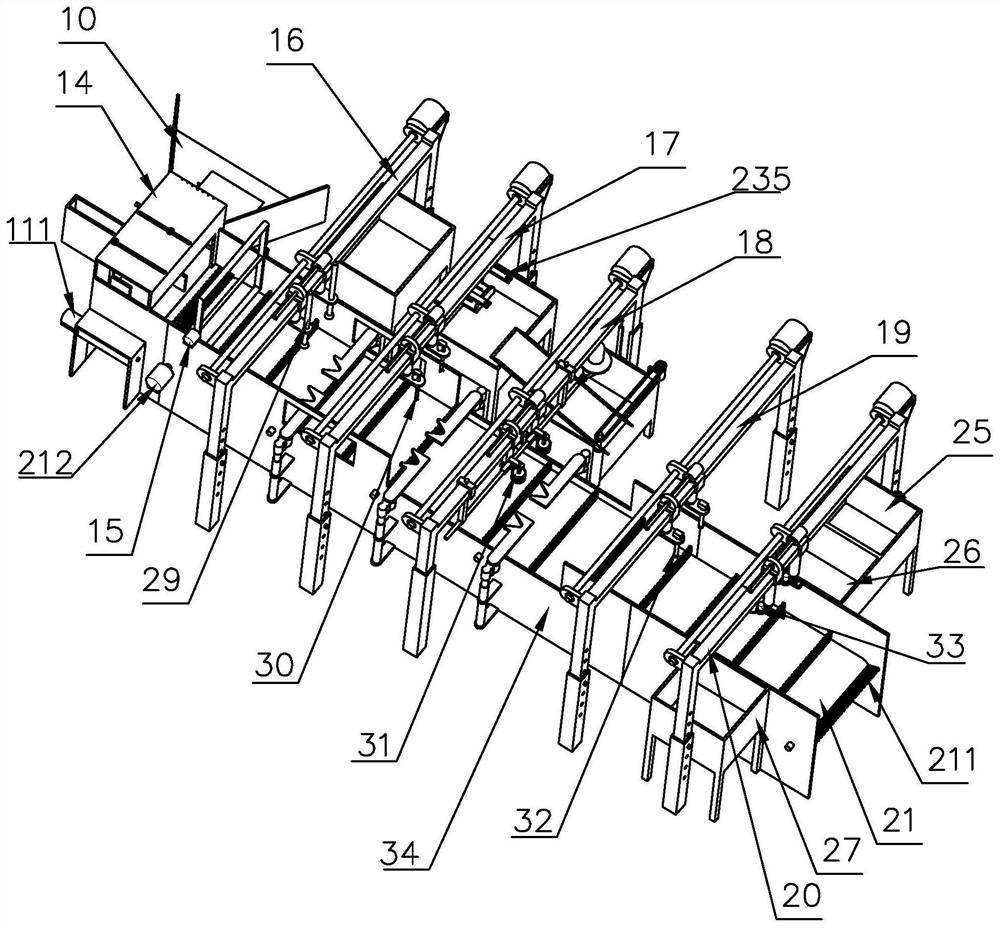

[0032] In order to facilitate the understanding of those skilled in the art, the following Figure 1-14 , the technical solutions of the present invention are further described in detail.

[0033] A hazardous waste and solid waste pretreatment device, comprising a collection port 10, a feeding conveyor belt 11, a motor I111, a support guard 112, a motor II15, a blocking rod 151, a support frame I16, a support frame II17, a support frame III18, and a support frame IV19 , support frame V20, main conveyor belt 21, gear teeth 211, main conveyor belt motor 212, storage box I22, storage box II23, storage tank III24, acid tank 25, lye tank 26, storage tank IV27, fixing mechanism 28, suction cover Tube 29, cap pulling mechanism 30, cap screwing mechanism 31, PH detector 32, grab mechanism 33, rack 34, the collection port 10 is fixedly installed on the support guard plate 112, and a number of brackets are arranged on the support guard plate 112 A feeding conveyor 11 is laid on the idl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com