Assembled machining shed for building construction and manufacture and installation method thereof

A building construction and assembly technology, applied in the direction of architecture, industrial construction, building construction, etc., can solve the problems of inconvenient processing, overall disassembly and transportation, manpower, time, resource consumption, time and labor waste, etc. Achieve the effect of reducing the difficulty of installation and construction, reducing labor costs and reducing labor waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

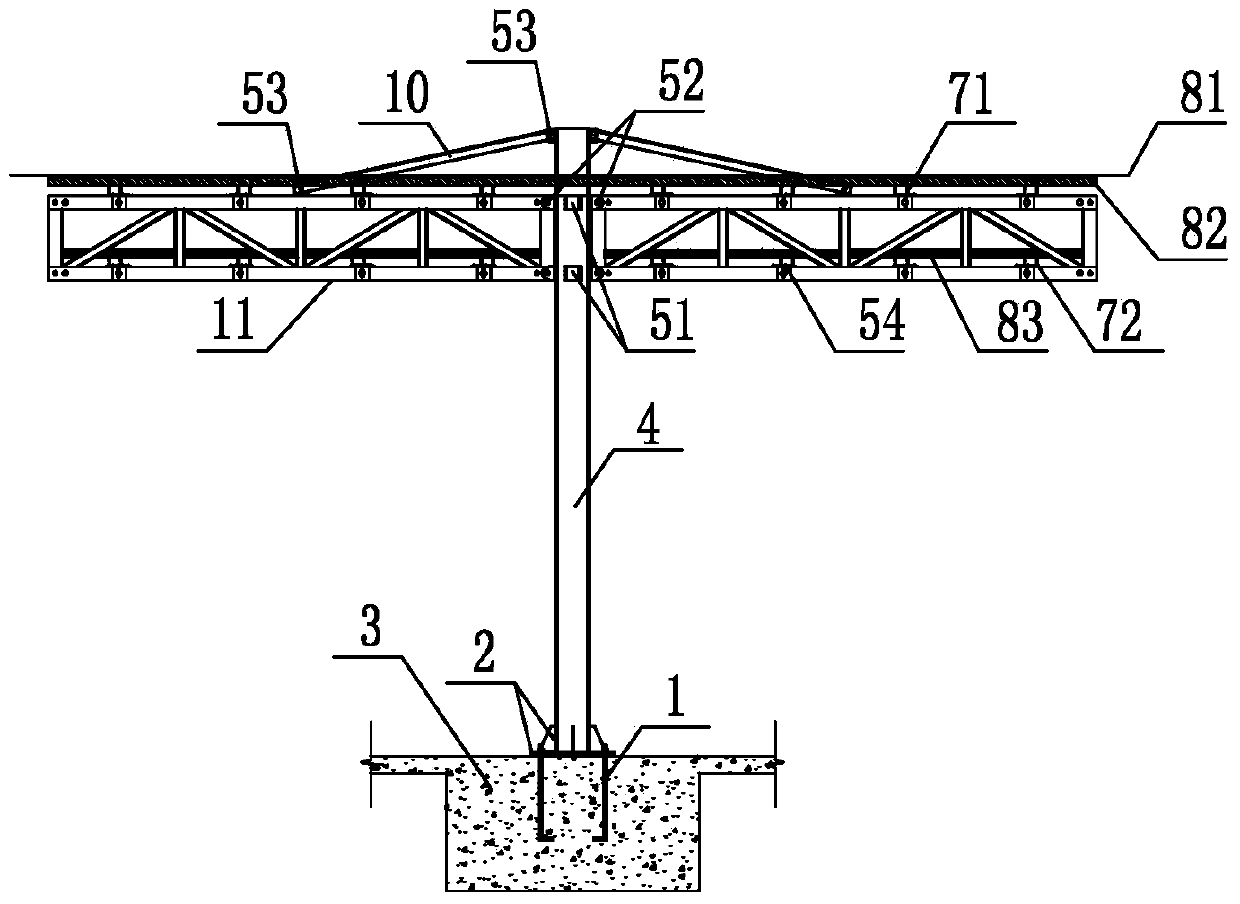

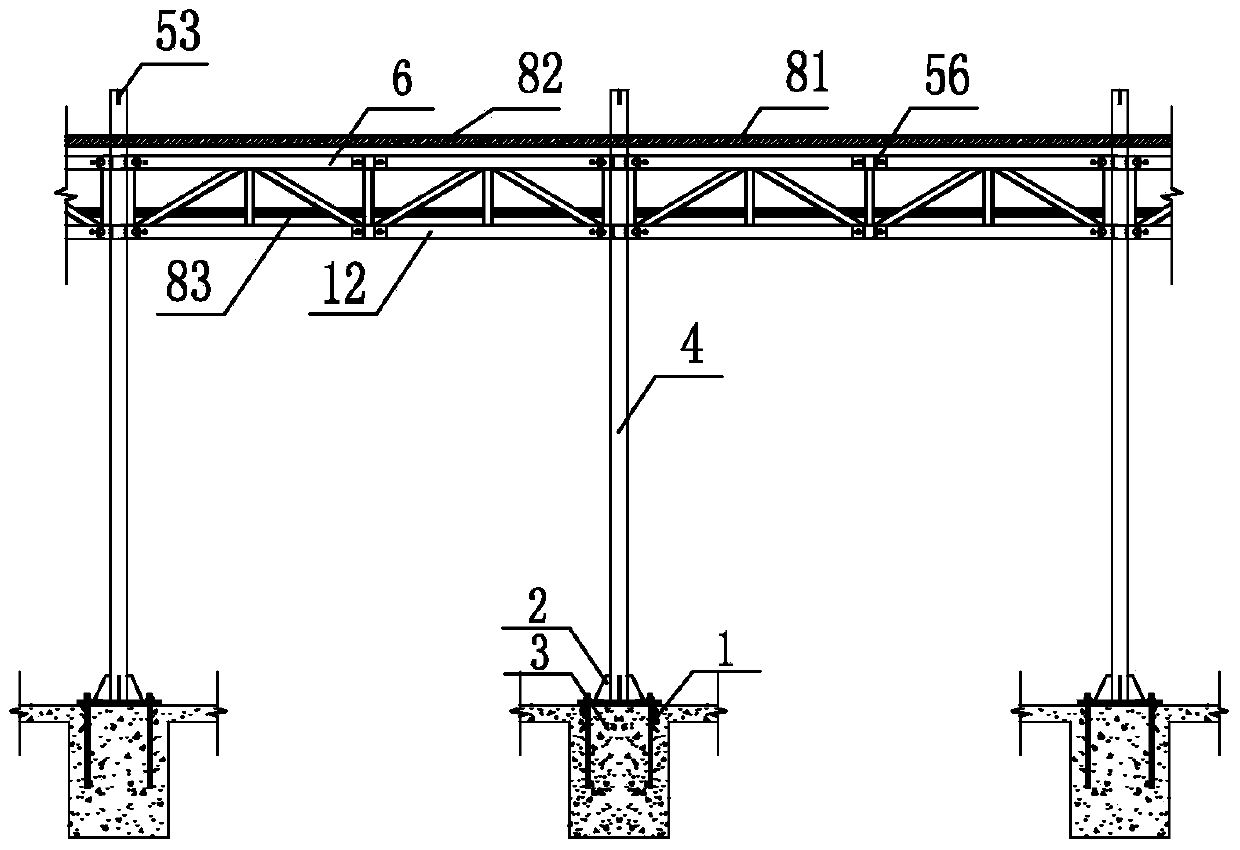

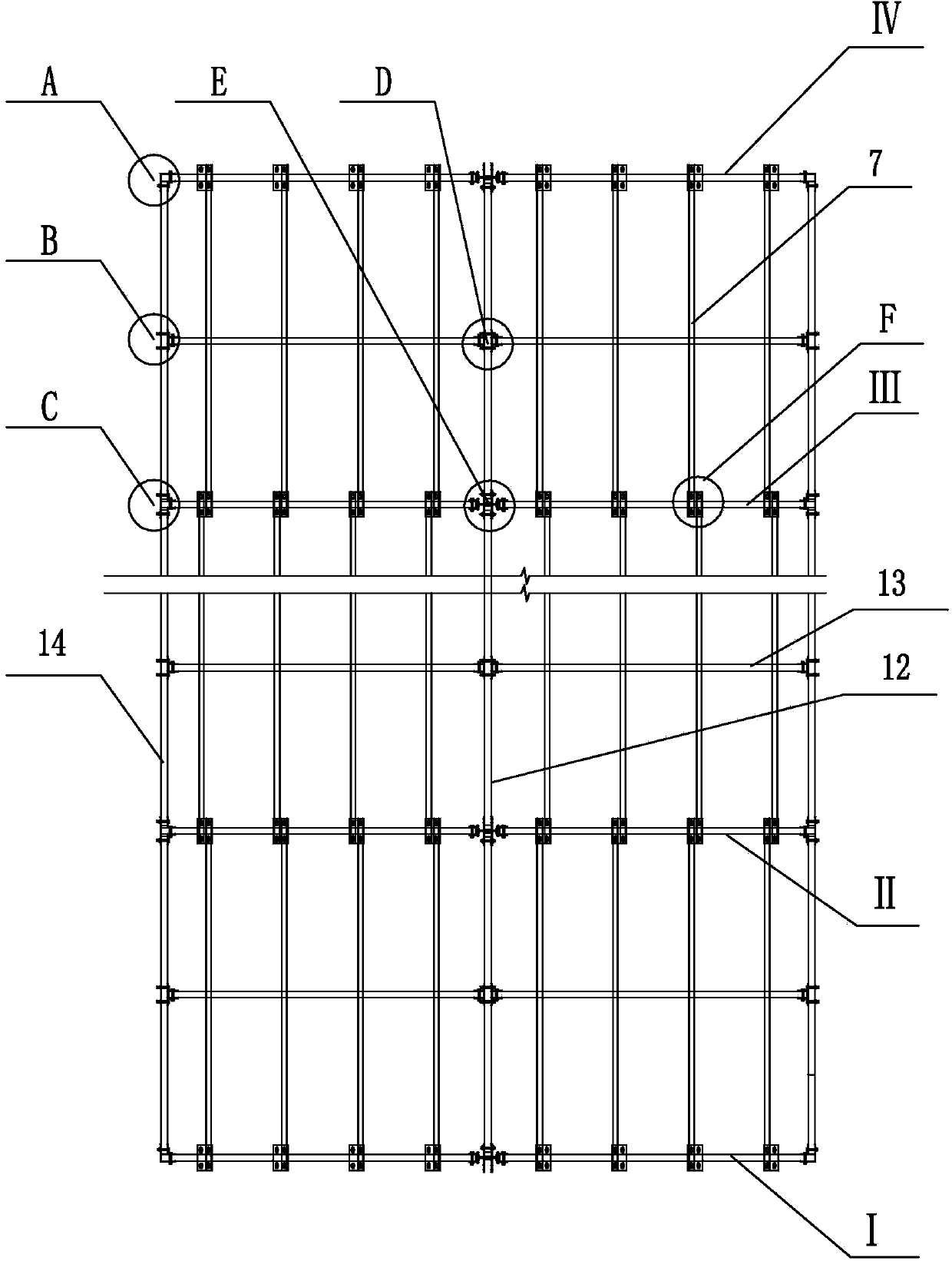

[0089] An assembled processing shed for building construction, such as Figure 1-Figure 3 As shown: the processing shed includes 4 sets of assembled T-shaped support body steel structures, multiple trusses a6 of the same specification and shed covers, and each group of assembled T-shaped support body steel structures includes a vertical support column 4, two The beam 11 formed by the truss a6 and the two slanting rods 10, the two slanting rods 10 are connected to the vertical support column 4 and the cross beam to form a T-shaped support body (see figure 1 ), each group of assembled T-shaped support body steel structures are connected by connecting pieces and bolts to the unit body truss 15 composed of truss a6, the longitudinal truss 12, the edge-banding truss 14 and the horizontal span connecting the vertical truss and the edge-banding truss The middle truss 13 forms an integral structural frame, on which the angle steel auxiliary keel 7 and the shed cover are arranged; the...

Embodiment 2

[0111] The method for making and installing the assembled processing shed for building construction described in Embodiment 1 comprises the following steps:

[0112] A. Basic setting and site hardening:

[0113] According to the positioning and laying out of the processing shed, the foundation pit is dug according to the foundation size, and the supporting anchor bolts 1 are accurately pre-buried to ensure that the position of the anchor bolts is consistent with the reserved hole of the welded steel plate at the lower end of the supporting column; finally, according to the size of the processing site If necessary, carry out concrete pouring and pounding for foundation and site hardening, and set up corresponding water and drainage ditches;

[0114] B. Assemble the T-shaped structure:

[0115] The steel structure of the assembled T-shaped support body adopts the I-beam as the vertical support column, and n pieces of steel components such as square-pass angle steel trusses a, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com