High-precision dynamic flow balance valve

A dynamic flow, high-precision technology, applied in balance valves, sliding valves, safety valves, etc., can solve problems such as inconvenient inspection, maintenance, cleaning, affecting the stiffness of the valve core, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

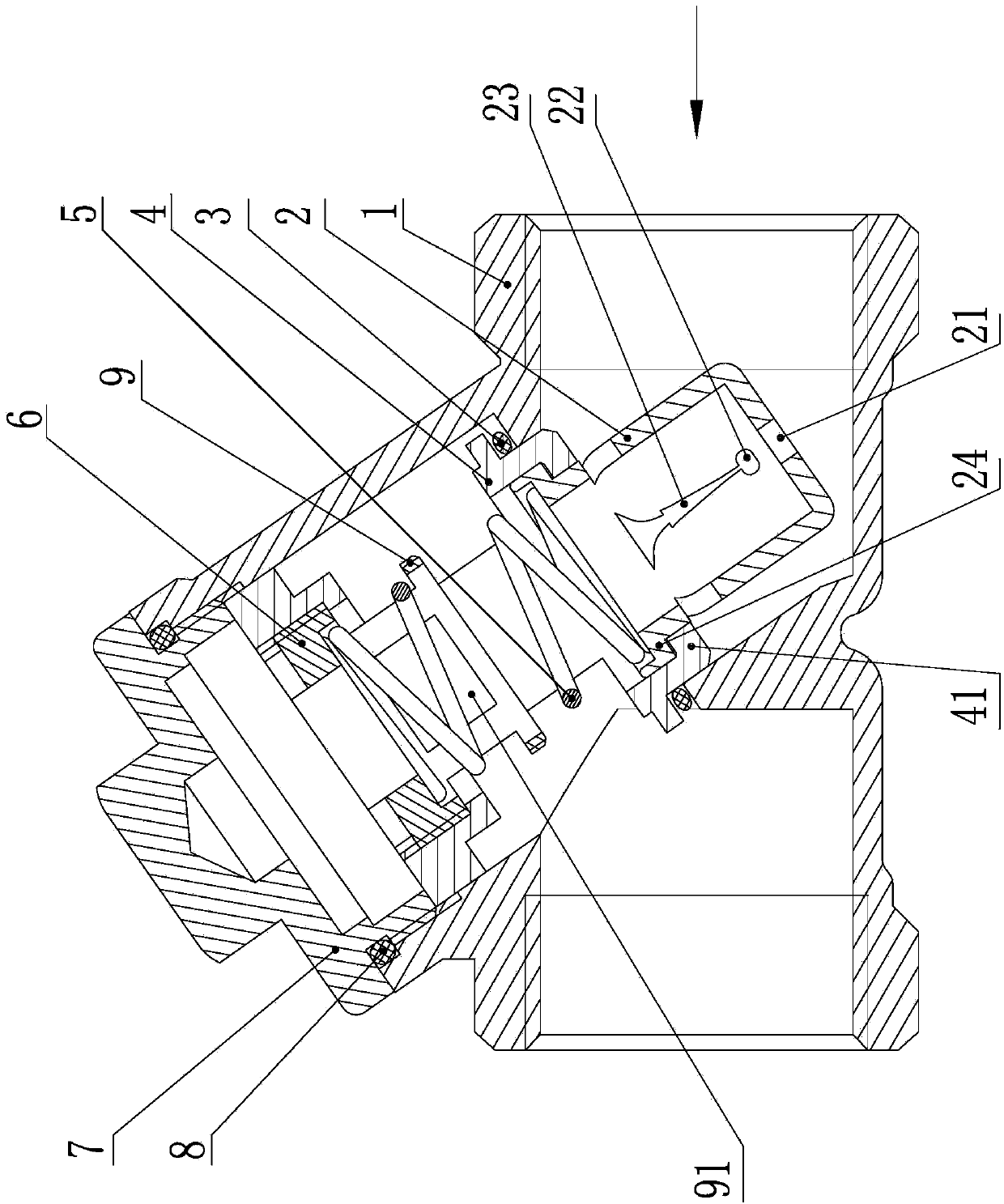

[0062] like figure 1 As shown, the high-precision dynamic flow balance valve of the present invention includes a valve core assembly and a valve cover 7 installed on the valve body 1. The valve core assembly is composed of a valve core 2, a valve core housing 4, a spring 5, and a locking screw 6. , the spool 2 is provided with a fixed hole 21 on the end surface and symmetrical side flow channels on both sides, the side flow channel includes two evenly distributed fixed elliptical holes 22, two or four evenly distributed variable holes 23, two fixed elliptical holes The holes 22 communicate with two symmetrically distributed variable holes 23 respectively.

[0063] In the case of small flow, the variable holes 23 in the present invention are set to two, and the two variable holes 23 are arranged symmetrically, and communicate with the corresponding fixed oval holes 22 one by one, while the two variable holes 23 The circulation area is the same.

[0064] In the case of a large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com