Elastic mounting structure for light-emitting diode (LED) lamp

An LED light board, flexible installation technology, applied in lighting devices, lighting device parts, lighting device cooling/heating devices, etc. The effect of a small damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

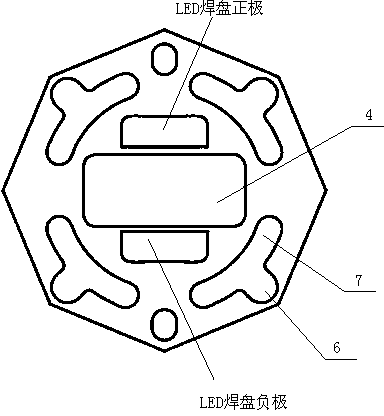

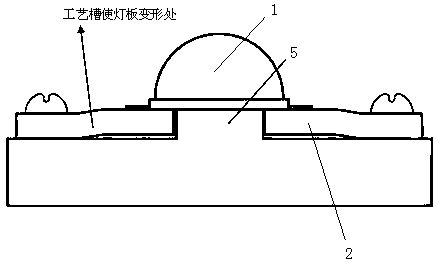

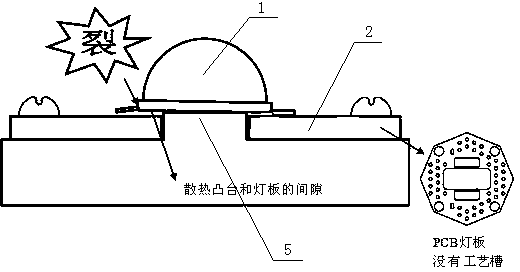

[0017] A flexible mounting structure for LED lamp boards, including LED lamps 1, lamp boards 2, and radiators 3. The lamp boards 2 are fixed on the radiators 3. There is a rectangular hollow structure 4 in the middle of the lamp boards 2. On the radiator 3, there is a The hollow structure 4 of the board 2 matches the heat dissipation boss 5, and the LED lamp 1 is fixed on the lamp board 2, and directly contacts with the heat dissipation boss 5. There are solder pads on both sides of the hollow structure 4, which are connected to the positive and negative electrodes of the LED lamp 1 .

[0018] Use the PCB substrate to make the light board 2, distribute four screw holes 6 evenly at the four corners of the light board 2, fix the light board 2 to the radiator 3 with screws, and make an arc-shaped next to each screw hole 6 The proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com