Linear calibration method

A linear calibration, to-be-calibrated technology, applied in measuring devices, instruments, special recording/indicating devices, etc., can solve problems such as deviation, affect production efficiency, and difficult algorithm, achieve improved accuracy, high universality, and reduced control The effect of computational difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings.

[0020] For the convenience of description, the present invention uses the current of the DC power supply module to describe in detail, and other similar instruments that require straight line correction, such as the weight of the weighing table, the detection quantities of the AC power supply module, temperature meters and other electronic instruments, can be used. Implemented using the scheme set forth in the present invention.

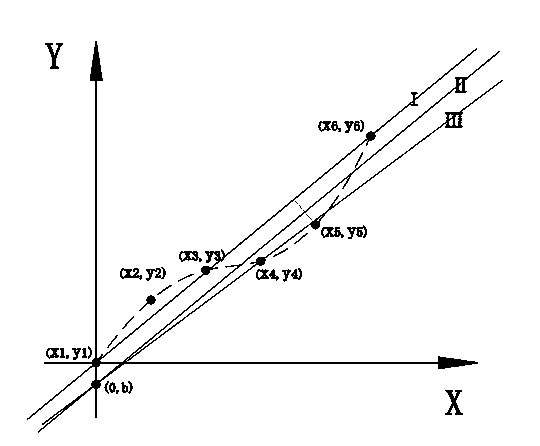

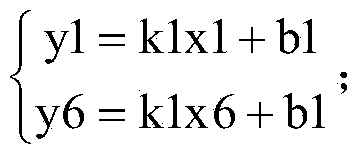

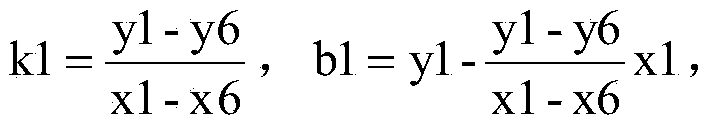

[0021] The invention uses a simple straight line equation to correct two quantities affecting the straight line, namely the slope k and the intercept b, so as to approximate the real situation as much as possible, so that the precision of each actual output value of the final point is within the error range. figure 1 For an embodiment, it is a two-dimensional coordinate system diagram composed of a set of ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com