Driving circuit of LED backlight and driving method thereof

A technology of backlight driving circuit and driving method, which is applied in the field of display screens to achieve the effects of increasing speed, improving correlation and reducing power output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

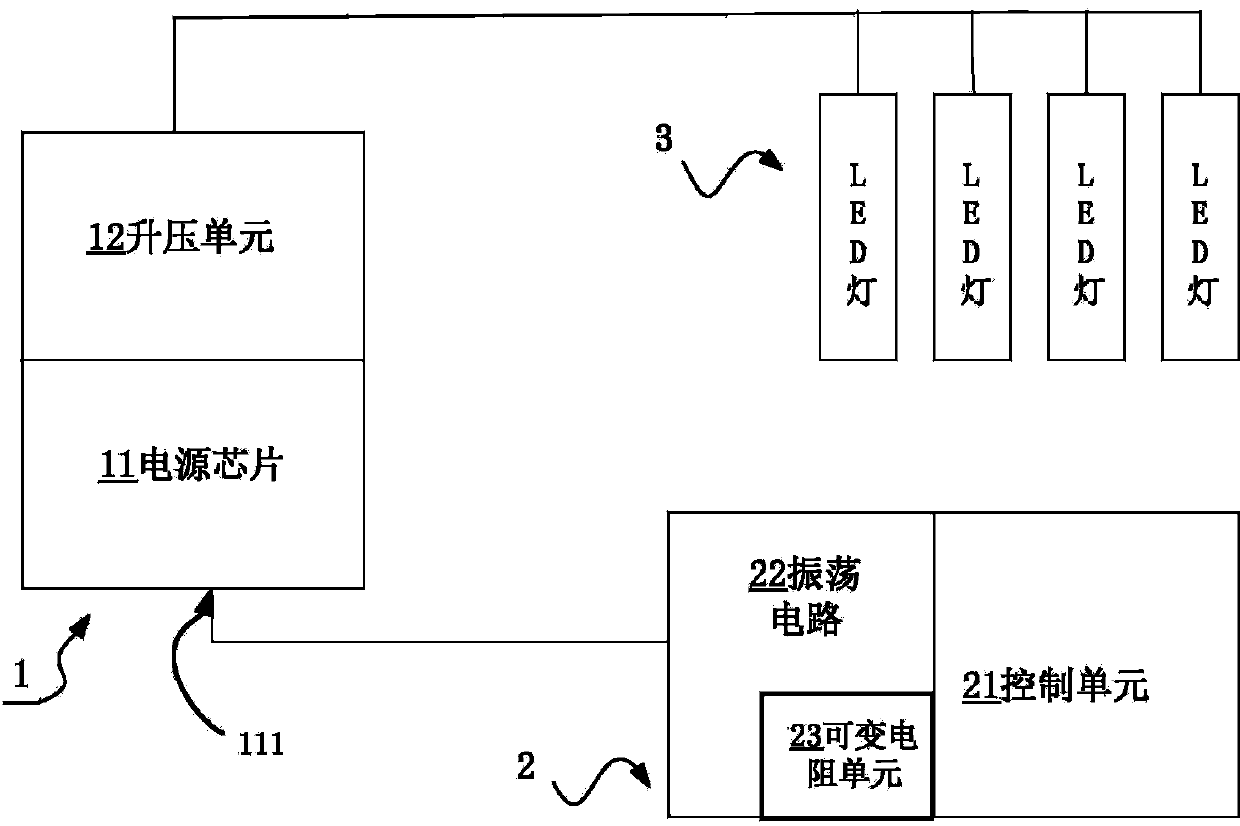

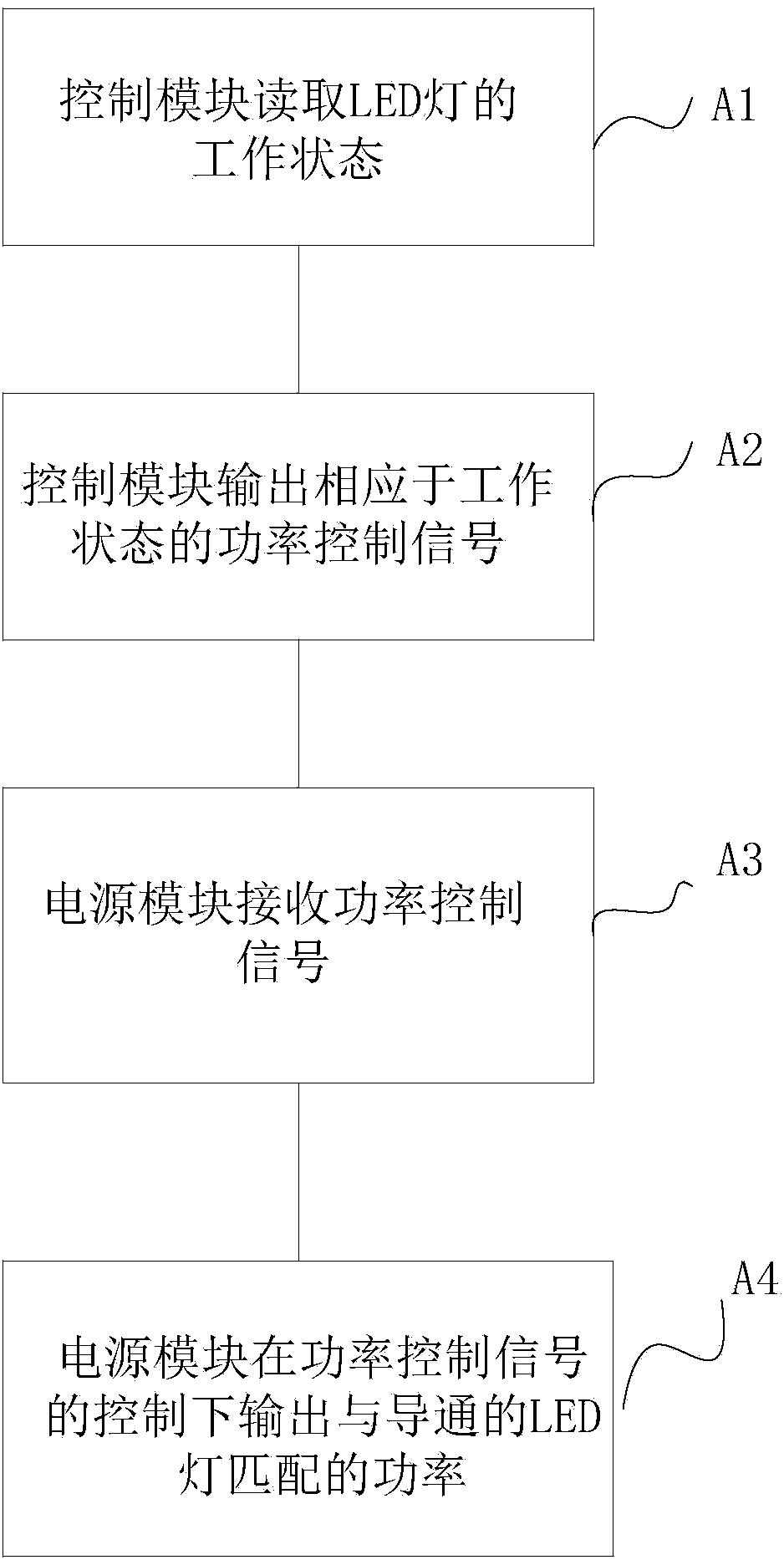

[0033] figure 1 It is a functional block diagram of a backlight drive circuit of the present invention, the drive circuit includes a power module 1, a control module 2 and at least two LED lamps 3, the control module 2 generates a power control signal according to the working state of the LED lamp 3, and the power module operates at power Under the control of the control signal, the output matches the power of the turned-on LED lamp.

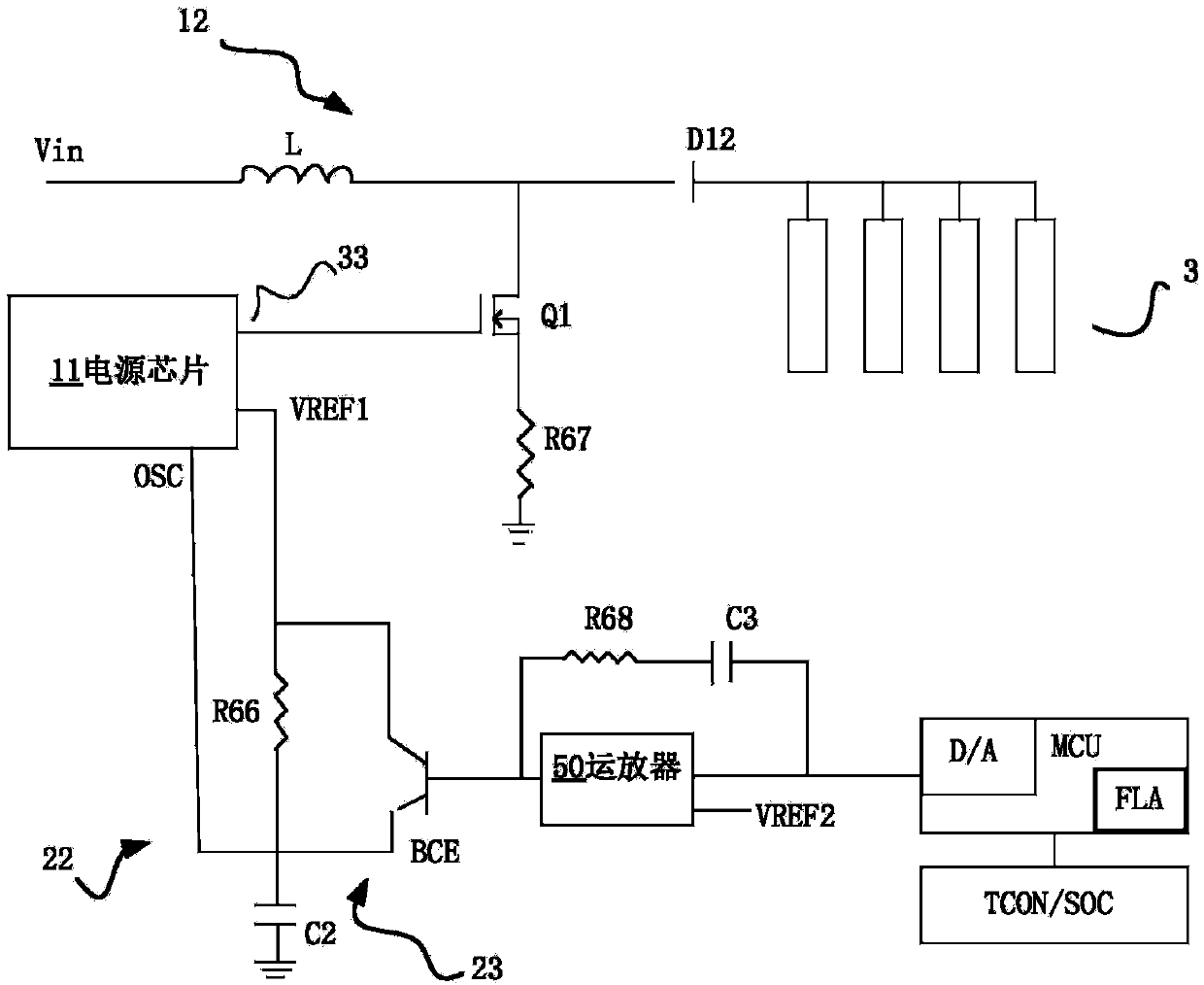

[0034] The above power module 1 includes a boost unit 12, a power chip 11, and the power chip 11 controls the output power of the boost unit 12 through frequency; the power chip 11 includes a frequency control pin 111; The control module 2 includes an oscillating circuit 22 and a control unit 21, the oscillating circuit 22 includes a variable resistance unit 23; the control unit 2 generates a resistance control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com