A protective cover rotation assembly structure and a contactor with the structure

An assembly structure and protective cover technology, applied in the direction of protective switch terminals/connections, relays, electromagnetic relays, etc., can solve the problems of low reliability of fixed limit and difficulty in meeting the requirements of the shortest leakage path of contactor products, etc., and achieve easy processing and realization , good phase-to-phase insulation performance, reliable and stable installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

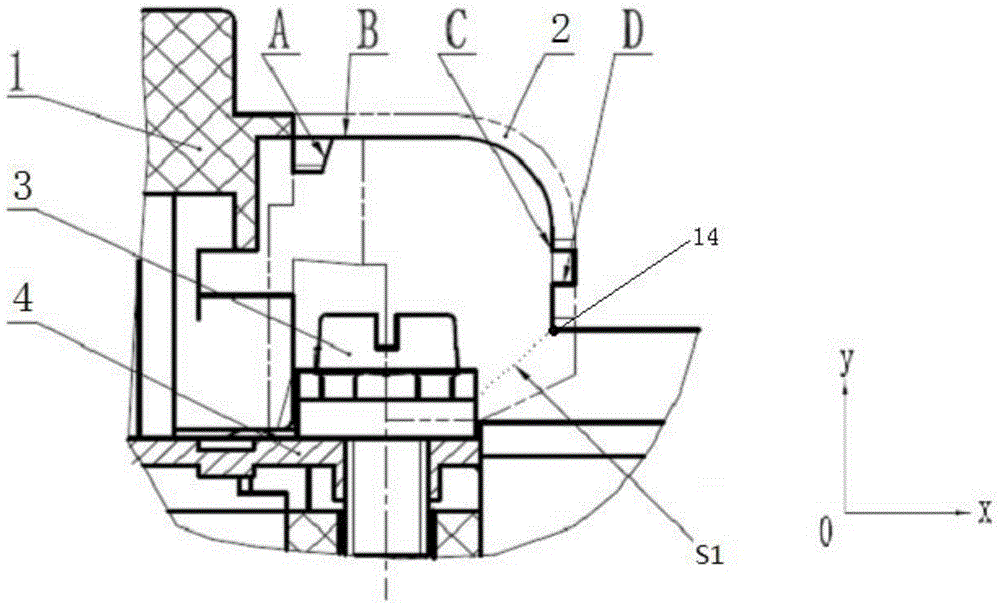

[0057] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

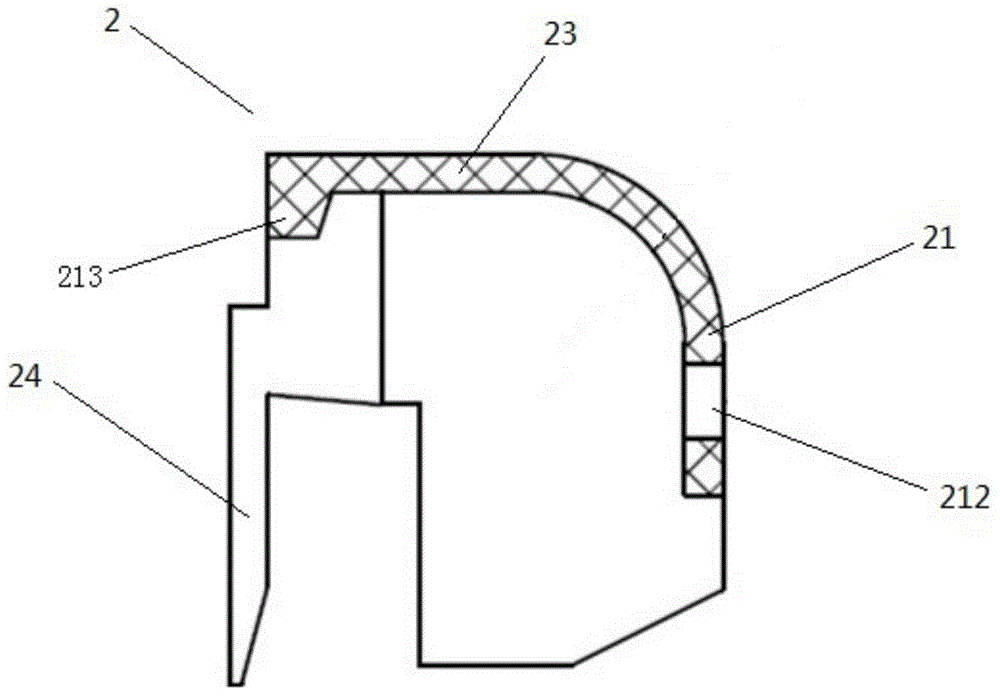

[0058] The protective cover rotation assembly structure of the present invention is used to install the protective cover 2 on the housing 1, such as Figure 4 and 5 shown.

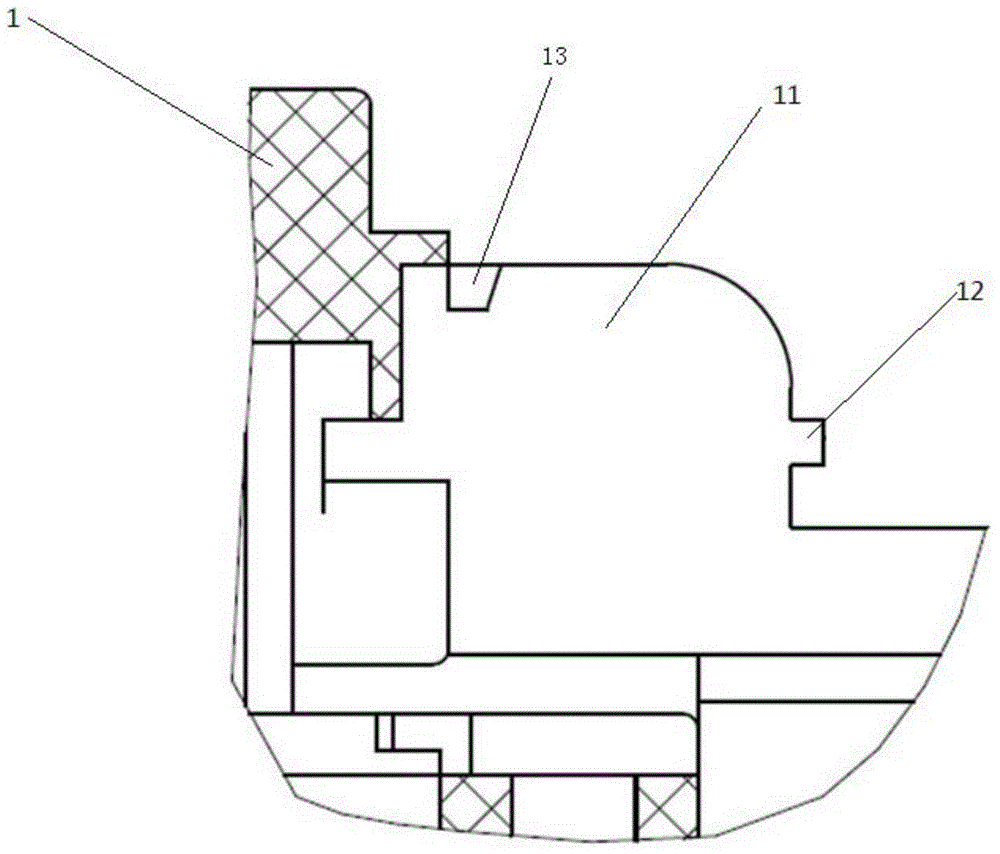

[0059] The housing 1 includes several insulating barrier walls 11 arranged at even intervals, a phase live conductor is arranged between two adjacent insulating barrier walls 11 , and a phase between the charged conductor and the adjacent two insulating barrier walls 11 There is a certain gap between them. The contactor in this embodiment is a contactor with four-phase electrified conductors; the electrified conductors are composed of tile-shaped terminal screws 3, contact plates 4, and w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com