Microphone and assembly method thereof

An assembly method and microphone technology, applied in the field of acoustics and electricity, can solve the problems of large internal space of the microphone, small acoustic cavity behind the microphone, complicated assembly process, etc., and achieve the effects of simple assembly process, simplified assembly process, and reduced assembly links.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

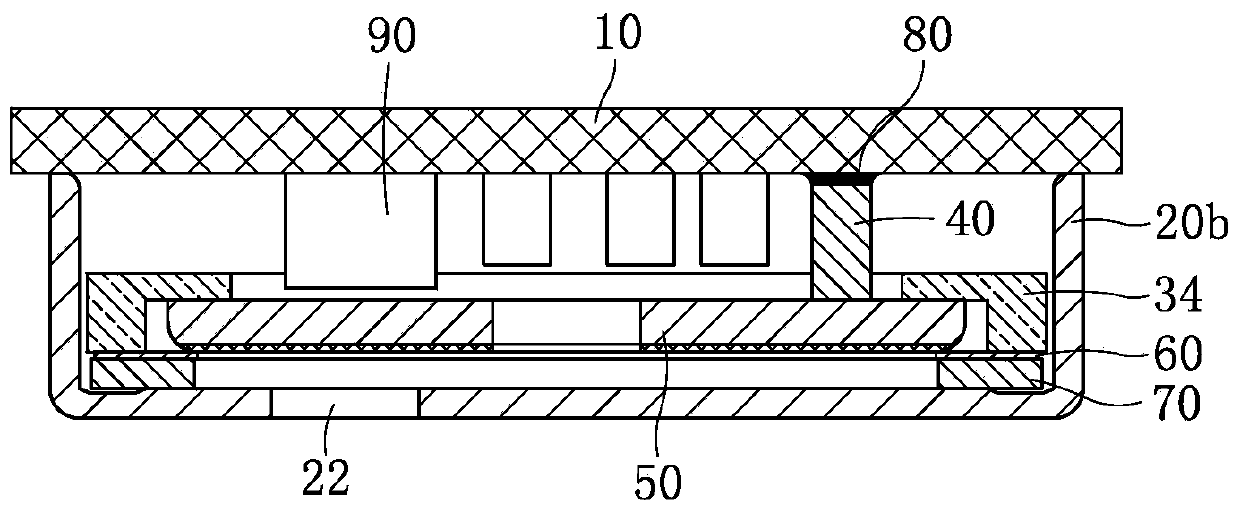

[0031] Such as figure 2 As shown, a microphone includes a circuit board 10 and a shell 20b with an open end. The open end of the shell 20b and the circuit board 10 are integrated and packaged. It is defined that the side of the circuit board 10 located inside the package is the inside, and the side located outside the package is the outside; the side of the housing 20b located inside the package is the inside, and the side located outside the package is the outside. The inner side of the circuit board 10 is provided with a number of electronic components 90, and the inner side of the housing 20b is provided with a diaphragm 70, a gasket 60 and an electrode plate 50 in sequence. The electrode plate 50 and the circuit board 10 are electrically connected by a conductive post 40, the conductive post 40 It is fixed and electrically connected with the circuit board 10 by the conductive glue 80, and the conductive glue can absorb the tolerances formed during the processing of various ...

Embodiment 2

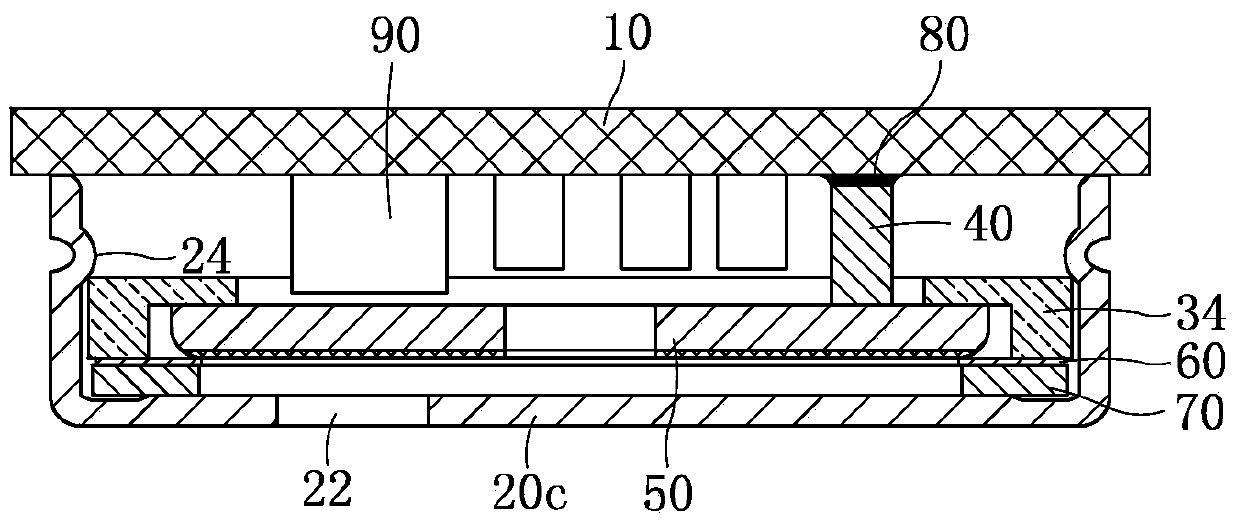

[0041] Such as image 3 As shown, this embodiment is basically the same as the first embodiment, and the difference lies in:

[0042] At least two bosses 24 are provided on the inner side wall of the housing 20c, and the bosses 24 are equally spaced at the same height of the side wall of the housing 20c. Each boss 24 is arranged at the edge of the insulating cavity 34 close to the circuit board 10, and is used to restrain the insulating cavity 34 from biasing or moving in the direction of the circuit board 10, so as to ensure the stable position of the electrode plate 50. This implementation In the manner, even if the insulating cavity 34 is not fixedly connected to the gasket 60, the electrode plate 50 will not be misaligned.

[0043] The preferred solution is to provide four bosses 24, one on each side wall of the housing 20c, which can more effectively ensure that the position of the insulating cavity 34 is stable without offset or misalignment, thereby more effectively ensuring...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap