Rotary telescopic mechanism for grass trimmer

A telescopic mechanism and a lawn mower technology, applied in the field of lawn mowers, can solve the problems of needing to operate a handle part or a machine head, inconvenient and user-friendly, cumbersome assembly process, etc., and achieve reliable performance, convenient operation and comfort, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

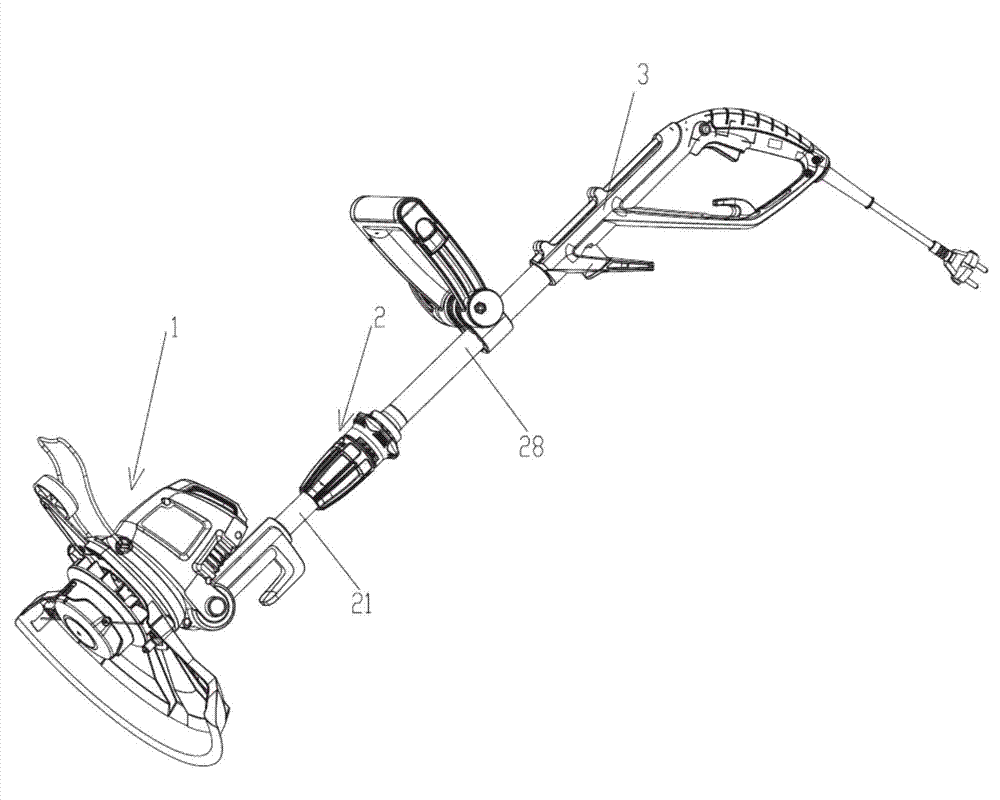

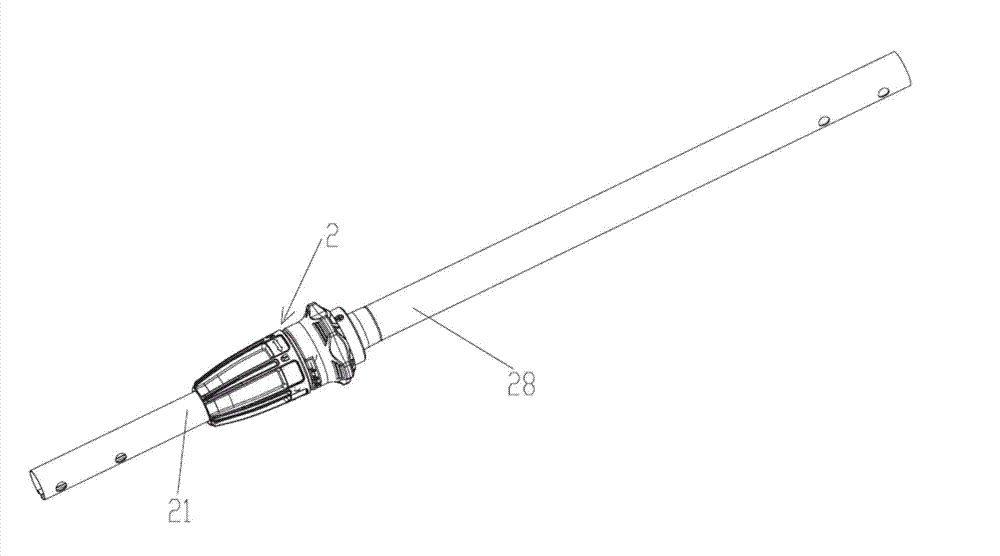

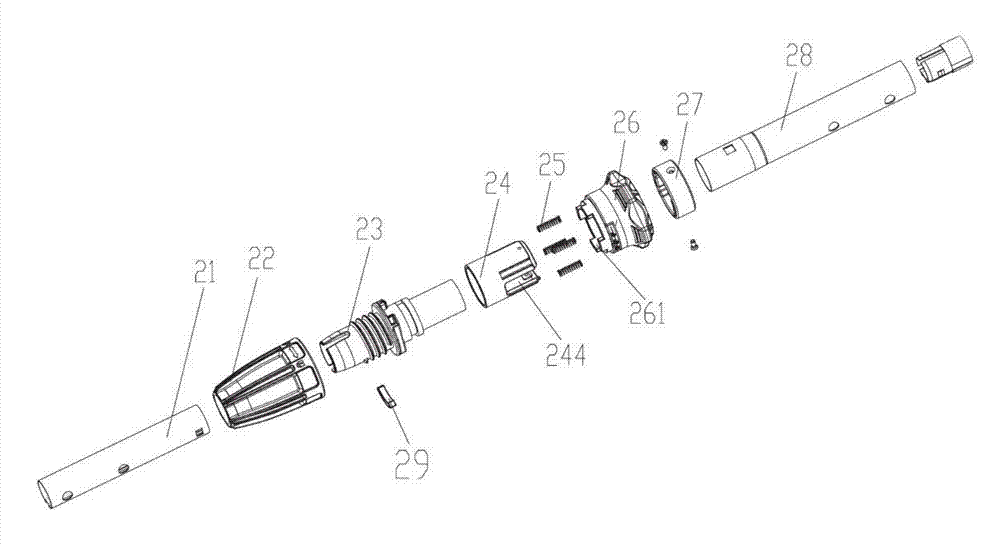

[0024] refer to figure 1 , corresponding to the preferred embodiment of the mower of the present invention includes a machine head 1, a handle 3 and a rotating telescopic mechanism 2 between the machine head 1 and the handle 3. Wherein, the handle part 3 is provided with an upper tube 28, and the machine head 1 is equipped with a lower tube 21, and the lower tube 21 is partially inserted in the upper tube 28, and the upper and lower tubes 28, 21 are all made of metal materials .

[0025] The above-mentioned rotary telescopic mechanism 2 is arranged between the upper tube 28 and the lower tube 21, which not only enables the upper and lower tubes 28, 21 to expand and contract in the length direction to adapt to users of different heights, but also enables the upper and lower tubes 28 to , 21 rotate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com