Gate type baking and subpackaging mechanism

A sub-packaging and gate-type technology, applied in the field of food processing, can solve the problems of low efficiency, time-consuming and laborious, and large equipment space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

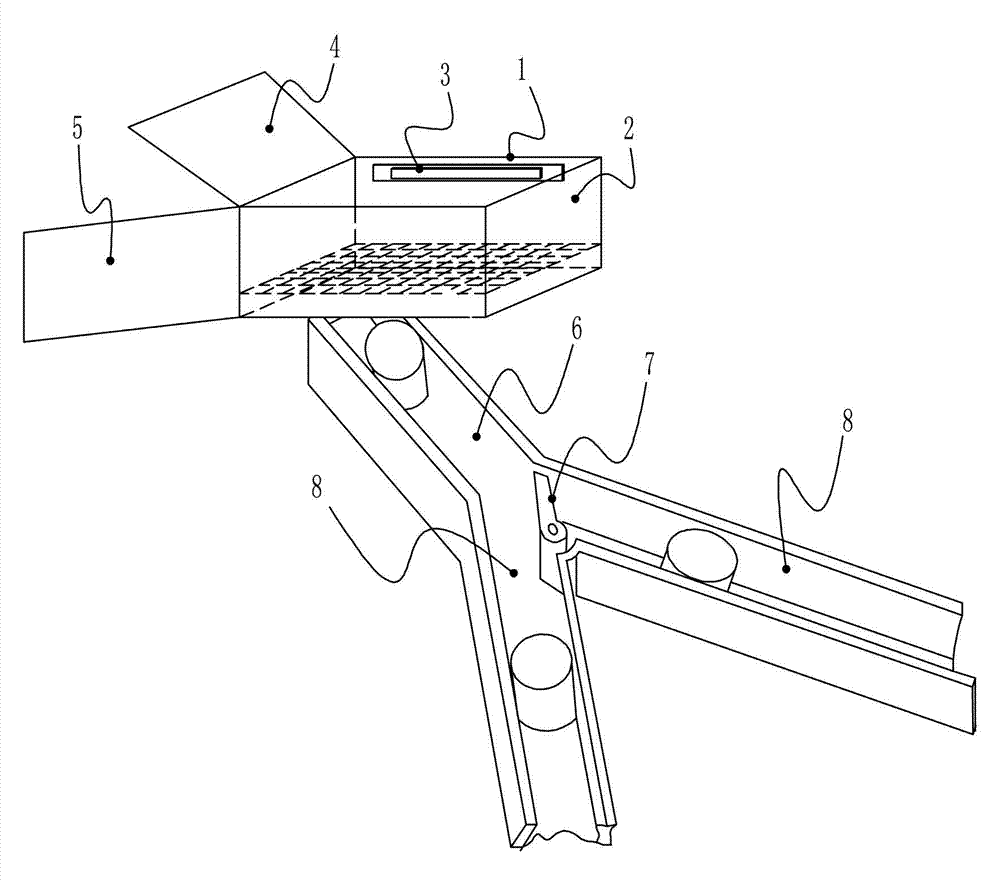

[0012] like figure 1 Shown: the gate-type baking sub-packaging mechanism, including a baking part and a sub-packing part. A discharge door 5, a grill 2 is installed inside the oven 1, and a push claw 3 is installed on the back of the oven 1. The push claw 3 is a flat plate structure and is connected with a cylinder; The separation plate 7 and the separation chute 8, the end of the feed chute 6 is connected to two separation chutes 8, and the separation plate 7 of the swinging opening and closing separation chute 8 is installed at the junction of the two, the length of the separation plate 7 and the feeding The width of chute 6 is the same.

[0013] During work, use the baking section to bake pastries, and after baking, drop the pastries directly into the packaging section for separation, so that the two processes of baking and packaging can be integrated on one machine tool. Avoid the need for two institutions to exist independently in the existing structure. Processing met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com