Chicken feed forming circular mold and reamer used for machining forming holes

A technology for forming holes and forming rings, which is applied in the field of reaming drills, can solve the problems of short service life of ring molds, increased feed powder content, complicated processes, etc., so as to achieve longer service life, improve processing efficiency, and ensure coaxiality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the examples do not constitute a limitation to the present invention.

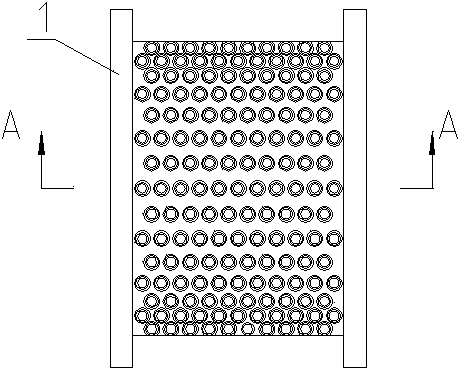

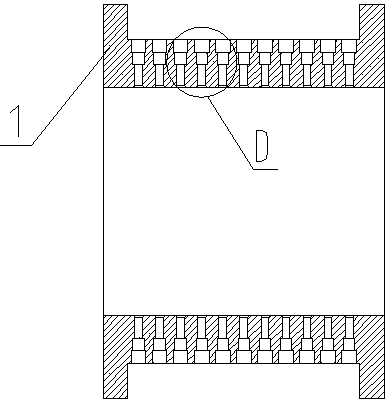

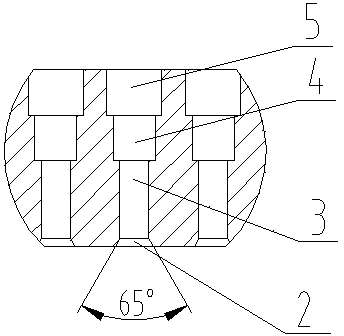

[0016] see Figure 1 to Figure 3 , the chicken feed forming ring die includes an annular die body 1, and the inner wall and outer wall of the ring die body 1 are provided with a feed port 2, a primary forming hole 3, a secondary forming hole 4, and a tertiary forming hole in sequence. Hole 5, the feed inlet 2 is a 65° conical mouth, the diameter of the first-stage forming hole 3 is designed to be 2.5 mm, the diameter of the second-stage forming hole 4 is 1.1 times the diameter of the first-stage forming hole 3, and the third-stage forming The diameter of the hole 5 is 1.1 times of the diameter of the secondary forming hole 4, the length of the primary forming hole 3 is 10 times of its diameter, and the total length of the secondary forming hole 4 and the primary forming hole 3 is 10 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap