Orthodontic self-ligating bracket

A self-locking bracket and orthodontic technology, applied in the field of orthodontics, can solve the problems of difficult manufacturing, difficult operation, complicated structure, etc., and achieve the effect of simple production, no tedious operation and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

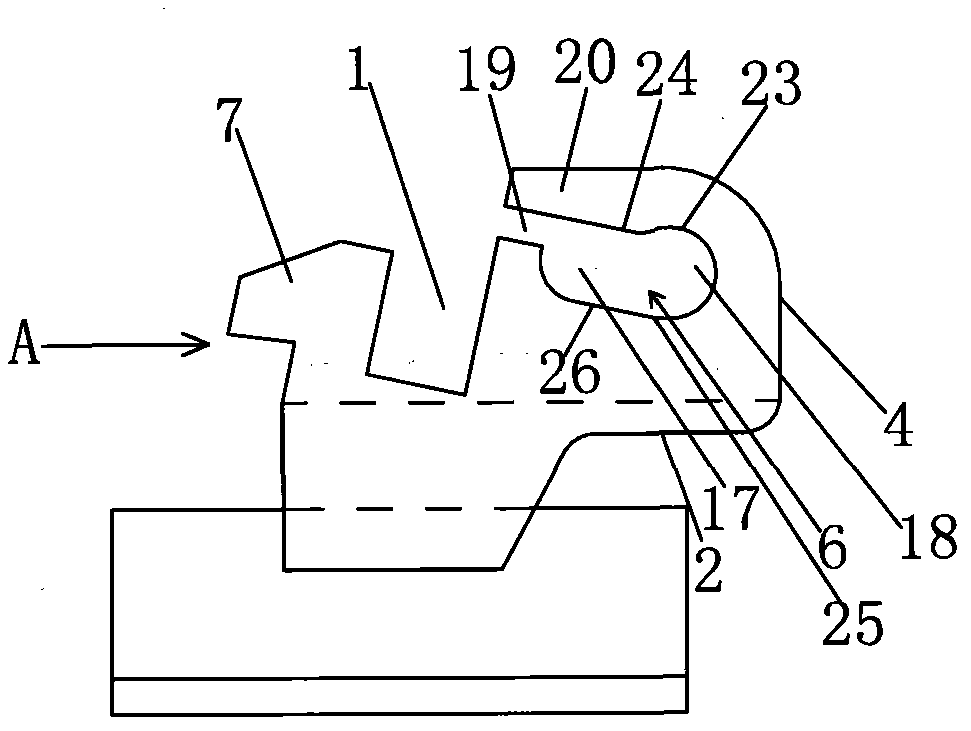

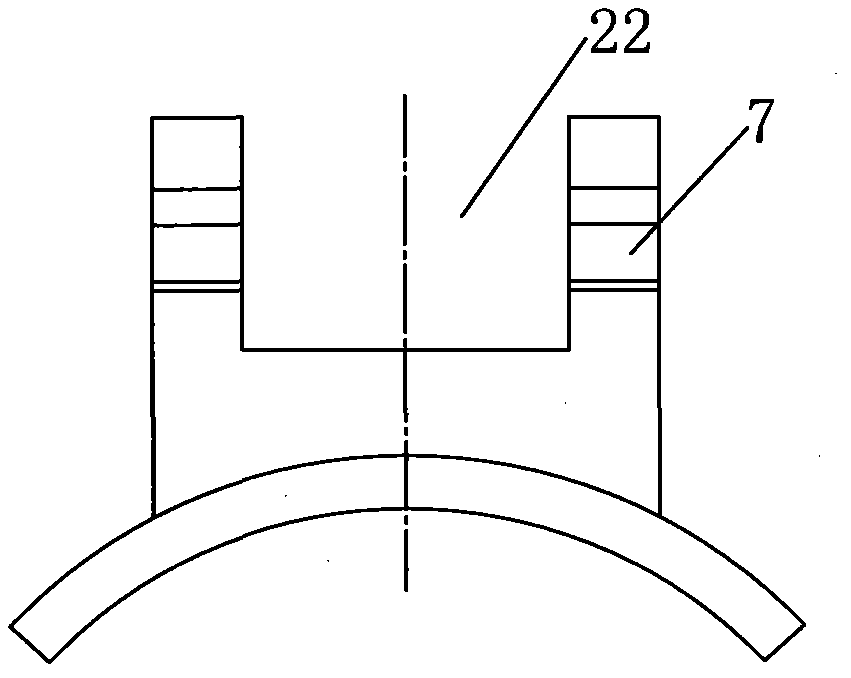

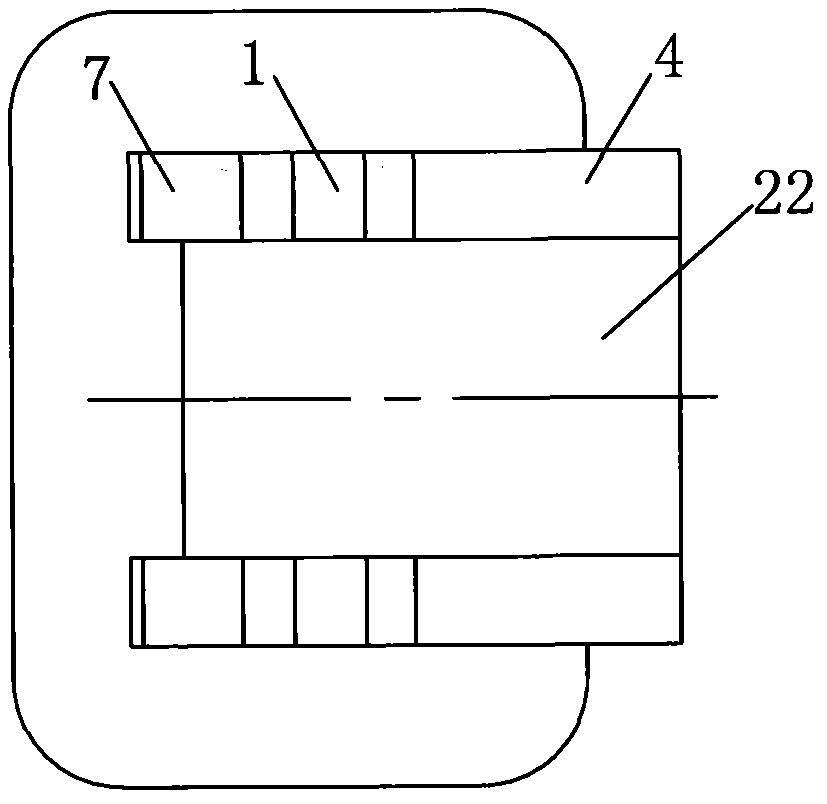

[0034] Embodiment 1: A self-ligating bracket for orthodontics, such as Figure 1~3 As shown, it includes a bracket body 2 with an archwire groove 1 and a bracket cover 8 matched with the bracket body 2. The right side of the archwire groove 1 is provided with a working wing 4. The intersecting thread groove groove 1 is provided with bracket opening 22; Figure 4~6 As shown, the bracket cover 8 is T-shaped as a whole, and the bracket cover 8 includes a wide portion 9 and a narrow portion 10. A shaft hole 12 formed by wire cutting is provided on the flange 11 on the bottom surface of the narrow portion 10 of the bracket cover. The narrow portion 10 of the bracket cover is disposed in the bracket opening 22, and a pin shaft 13 is pierced in the shaft hole 12 of the narrow portion 10 of the bracket cover, and the pin shaft 13 is cylindrical.

[0035] On the working wing 4 on the right side of the arch wire groove 1, there is a kidney hole 6 formed by wire cutting. The kidney hole...

Embodiment 2

[0042] Embodiment 2: As a deformation to the bracket body, such as Figure 9 As shown, a protrusion 27 is provided in the middle of the upper end surface of the waist hole 6 to limit the pin shaft. The protrusion 27 is an arc-shaped protrusion. Similarly, the protrusion can also be arranged under the waist hole. In the middle of the end face, there is an opening 19 formed by wire cutting on the working wing 4 on the right side of the archwire groove 1. The two sides of the opening 19 communicate with the archwire groove 1 and the kidney hole 6 respectively. The kidney hole 6 and the opening The part of the working wing above 19 forms a shrapnel 20 that can be deformed under force; in the locked state, the pin shaft is on the right side of the waist hole; when the bracket cover is opened, the pin shaft moves to the left and jumps over the protrusion 27 to force the shrapnel to generate Deform to enter the left side of the kidney hole.

Embodiment 3

[0043] Embodiment 3: As another deformation of the bracket body, such as Figure 10 As shown, in the direction perpendicular to the arch wire groove 1, the kidney hole 6 is divided into two sections, the left half section is a straight hole 17 with both upper and lower ends being straight lines, and the right half section is an arc-shaped hole 18. The bottom of the arc hole 18 is lower than the lower end face of the straight hole 17, the top of the arc hole is flush with the upper end face of the straight hole, and an L-shaped through hole 16 is cut down along the left end of the waist hole 6 to the right. The part surrounded by the L-shaped through hole 16 and the kidney hole 6 forms an elastic piece 20 that can be deformed under force; when in the locked state, the pin shaft is in the arc-shaped hole 18 on the right side of the kidney hole; when the bracket cover is opened, the pin The shaft leaves the arc hole to force the deformation of the shrapnel 20 and enters into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com