Hold-down device for filter plate of plate-type deduster

A compression device and dust collector technology, which is applied in the direction of dispersed particle filtration, chemical instruments and methods, and dispersed particle separation, etc., can solve the problem that the plate dust collector cannot be expanded in the vertical direction, the gas emission cannot meet the standard, and the filter plate cannot be installed horizontally, etc. problem, achieve adjustability, save space, and reduce complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

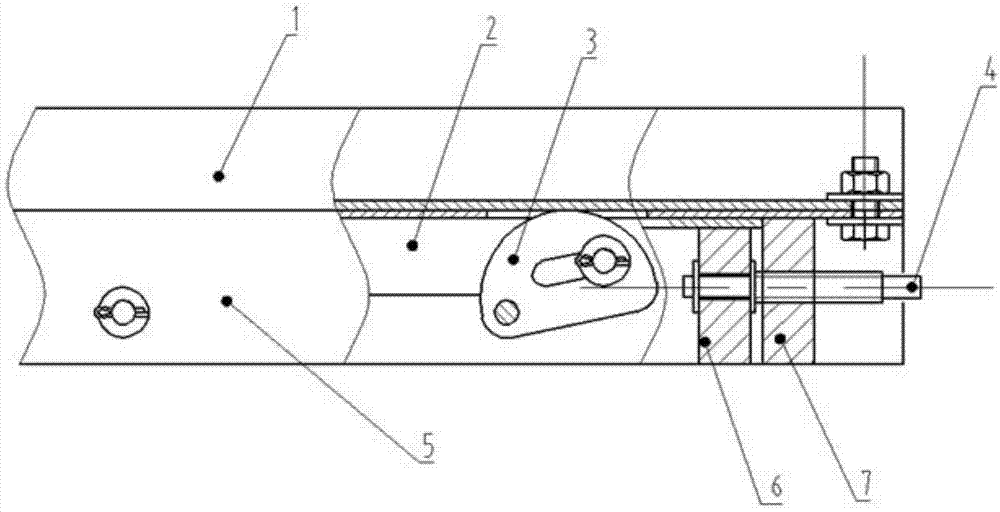

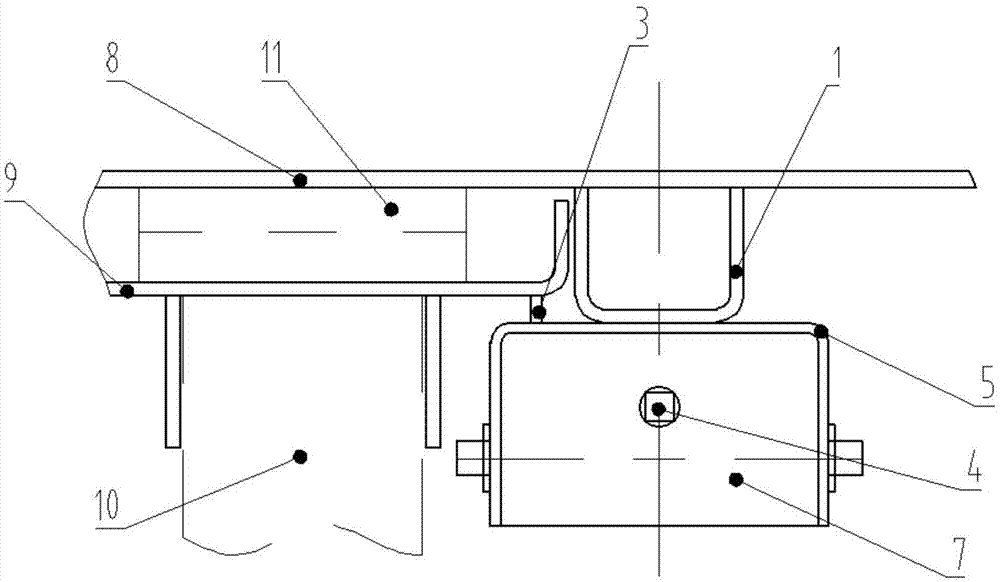

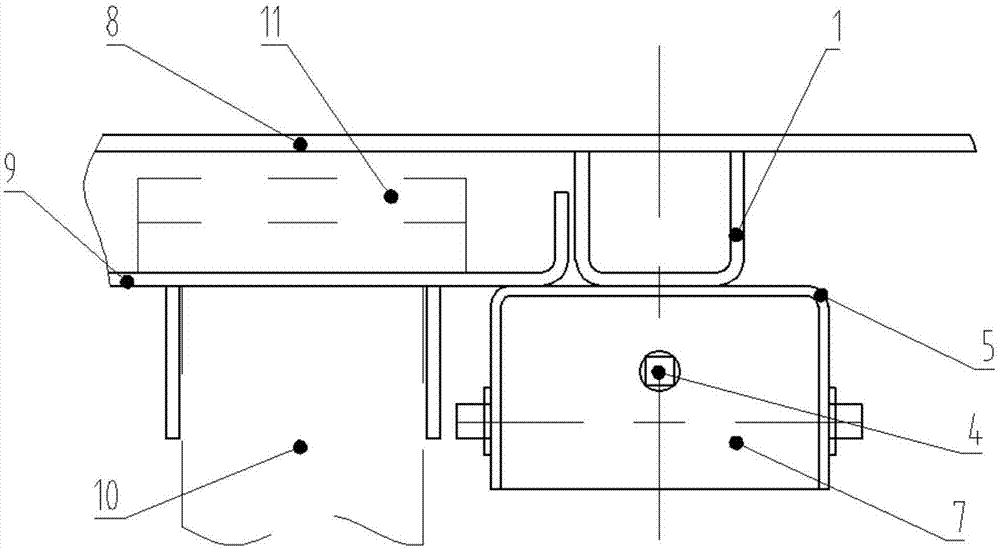

[0015] Such as figure 1 and figure 2 As shown, the filter plate pressing device of the plate type dust collector includes the installation channel steel 1 welded at the bottom of the flower plate 8, the installation channel steel 1 is connected with the guide rail 2 and the guide channel steel 5 through bolts, the guide rail 2 can move freely front and rear, and the guide rail 2 The support plate 3 is connected with the pin shaft, the support plate 3 is connected with the guide channel steel 5, and the front end of the guide rail 2 (with figure 1 The right side is the front end, the same below) is welded with a fixed block 6, and the front end of the guide channel steel 5 is welded with a threaded block 7, the guide rail 2 and the fixed block 6 are connected with the guide channel steel 5 and the threaded block 7 through the locking screw 4, through The screwing of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com