Semiautomatic disassembling device for crusher hammer head and disassembling method adopting semiautomatic disassembling device

A semi-automatic, pulverizer technology, applied in the direction of grain processing, etc., can solve the problems of high cost and low efficiency, and achieve the effect of reducing labor intensity and shortening the disintegration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In the following description, the same symbols are used for the same components.

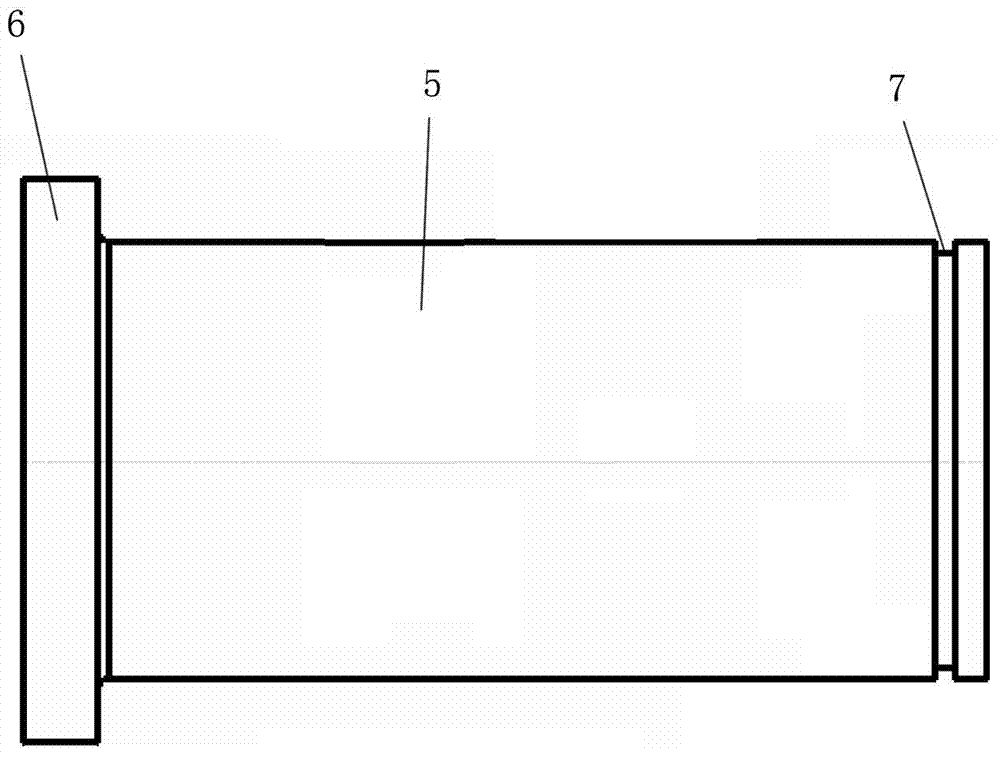

[0036] The semi-automatic dismantling device for the hammer head of the pulverizer of the present invention includes a hammer head threading pin removal assembly and a hammer head hammer handle separation assembly.

[0037] When dismantling the tup of the currently used hammer, since the shaft circlip 8 is easy to remove, the shaft circlip 8 can be manually removed earlier.

[0038] Then, through the hammerhead threading pin removal assembly of the present invention, the hammerhead threading pin 5 is removed.

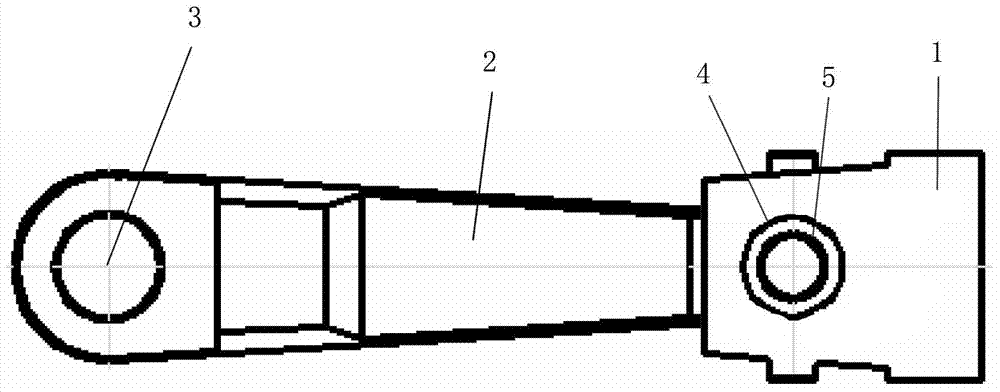

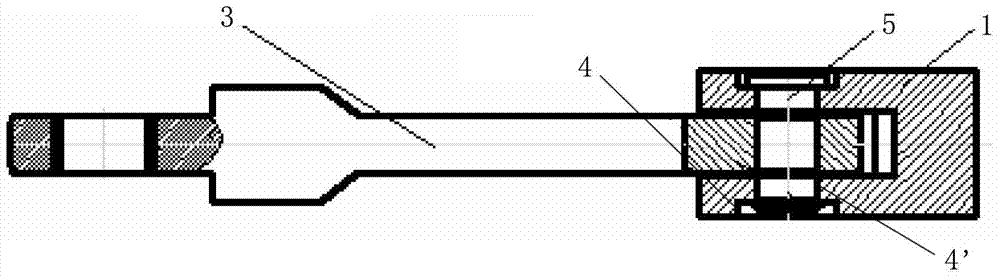

[0039] Figure 2A is a front sectional view showing the structure of a hammer pin removal assembly for removing a hammer pin, Figure 2B It is a plan view showing the structure of the hammer pin removal assembly for removing the hammer pin. Such as Figure 2A and Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com