Quick-disassembling and quick-replacing sucker rod centralizer and method

A technology of centralizer and sucker rod, applied in drill pipe, earthwork drilling, drilling equipment, etc., can solve the problems of time-consuming installation, reduced mandrel work efficiency, troublesome disassembly and installation, etc. Reduce installation and disassembly time and ensure the effect of normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

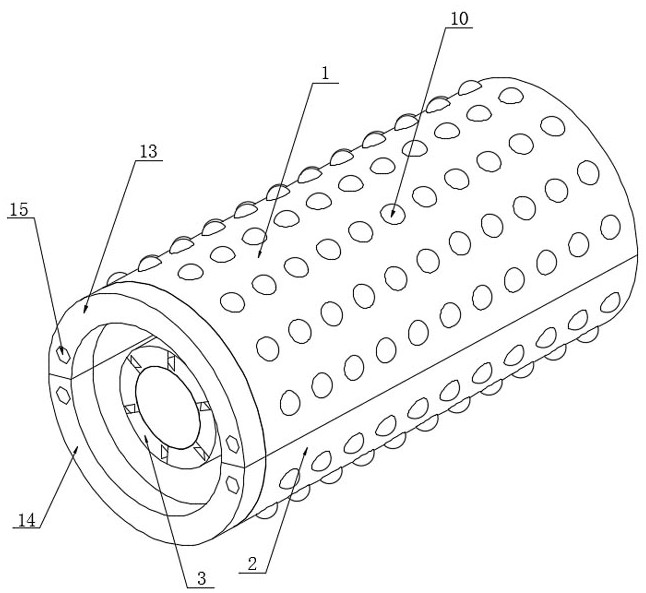

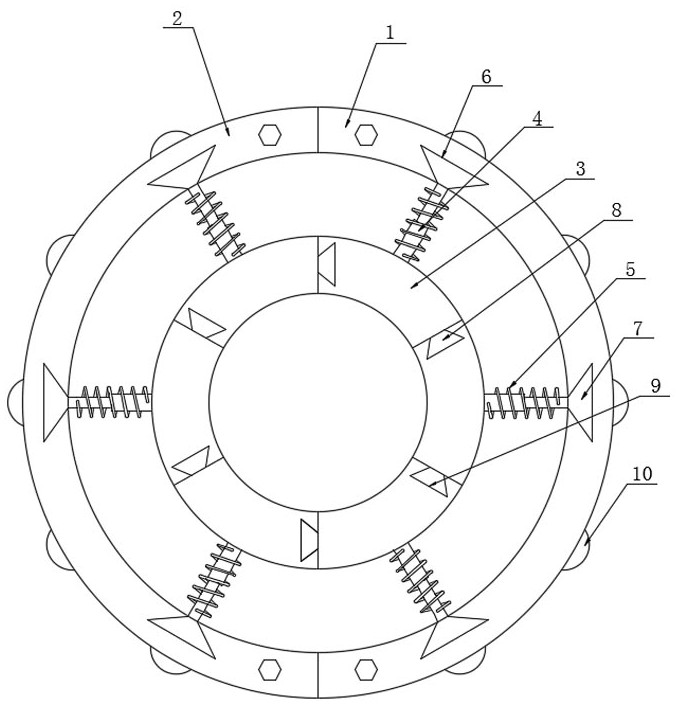

[0031] Embodiment 1, with reference to attached Figure 1-5 , a quick-release and quick-change sucker rod centralizer provided by the present invention includes a first semi-annular plate 1 and a second semi-annular plate 2, and the first semi-annular plate 1 and the second semi-annular plate 2. An auxiliary mechanism is provided inside, and the auxiliary mechanism extends out of the first semi-annular plate 1 and the second semi-annular plate 2;

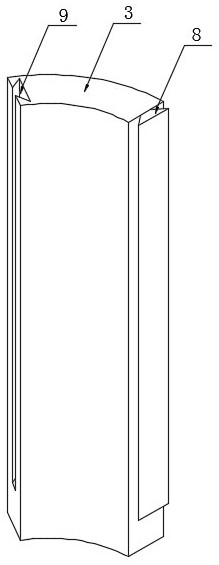

[0032] The auxiliary mechanism includes six clamping plates 3, and the six clamping plates 3 are all arranged inside the first semi-circular plate 1 and the second semi-circular plate 2, and the six clamping plates 3 are combined into a hollow cylinder, Each of the six clamping plates 3 is provided with clamping components, and the outside of the clamping plates 3 is fixed with a telescopic rod 4, and the outside of the telescopic rod 4 is provided with a spring 5, and the first semicircular plate 1 and the second Two semi-annular ...

Embodiment 2

[0042] Embodiment 2, with reference to attached Figure 6 , a quick-release and quick-change sucker rod centralizer provided by the present invention, the clamping assembly includes a second connection block 16, the second connection block 16 is fixed on one side of the clamp plate 3, and the second connection The other side of the block 16 is provided with a second connecting groove 17, and the cross-sectional shape of the second connecting groove 17 and the second connecting block 16 is T-shaped. And disassembly is more convenient.

[0043] A method of using a quick-release and quick-change sucker rod centralizer mentioned in the present invention includes the following process:

[0044] When using the present invention, through the design of the clamping assembly, the installation and disassembly between the six clamping plates 3 are more convenient, and at the same time, the clamping plates 3 are connected to the first semi-circular ring plate 1 and the second semi-circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com