Coffee grinding device

A coffee and grinding cavity technology, applied in grain processing and other directions, can solve problems such as poor extrusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

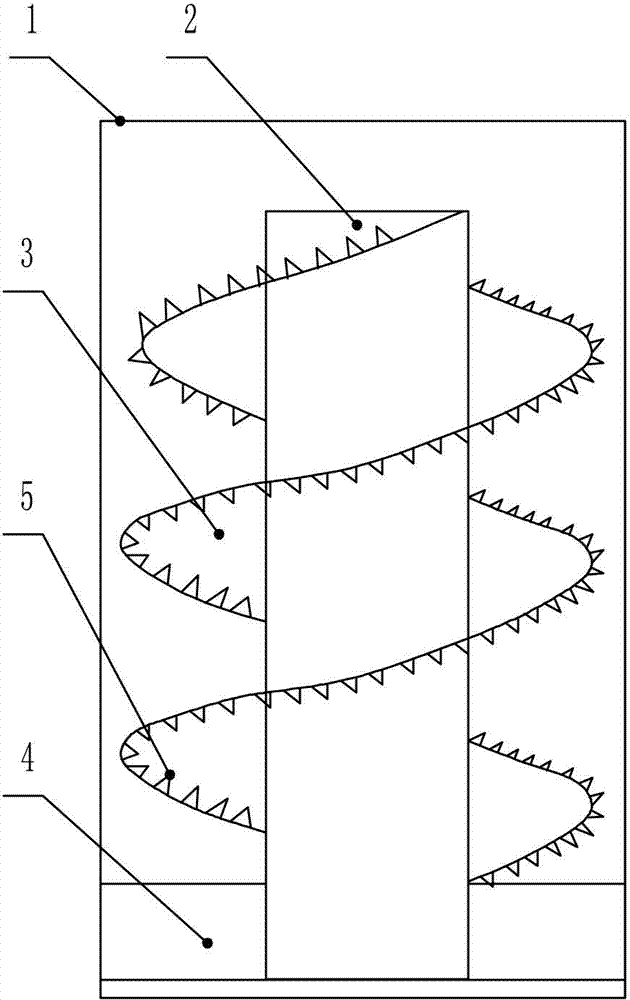

[0010] Such as figure 1 Shown: the coffee grinding device, including a grinding chamber 1, a rotating shaft 2, a spiral blade 3 and a material rejection plate 4, the grinding chamber 1 is a cylindrical cavity, the rotating shaft 2 is located in the grinding chamber 1, and the spiral blade 3 is fixed On the rotating shaft 2, the rejecting plate 4 is radially connected to the lower end of the rotating shaft 2, the length of the rejecting plate 4 is the same as the inner diameter of the crushing chamber 1, and the lower end surface of the rejecting plate 4 is in contact with the bottom surface of the crushing chamber 1, A wear-resistant layer is provided on the contact surface between the throwing plate 4 and the crushing chamber 1, and a number of conical toothed knives 5 are evenly fixed on the surface of the spiral blade 3, and the conical toothed knives 5 are arranged in a spiral shape, and the conical toothed knives 5 pointed outward.

[0011] When working, put the coffee b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com