Spanner

A wrench and trigger technology, applied in the field of wrenches, can solve the problems of easy deformation of the spring leaf, inconvenient normal use, large application, etc., and achieve the effects of preventing random rotation, reducing operation difficulty, and avoiding force damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

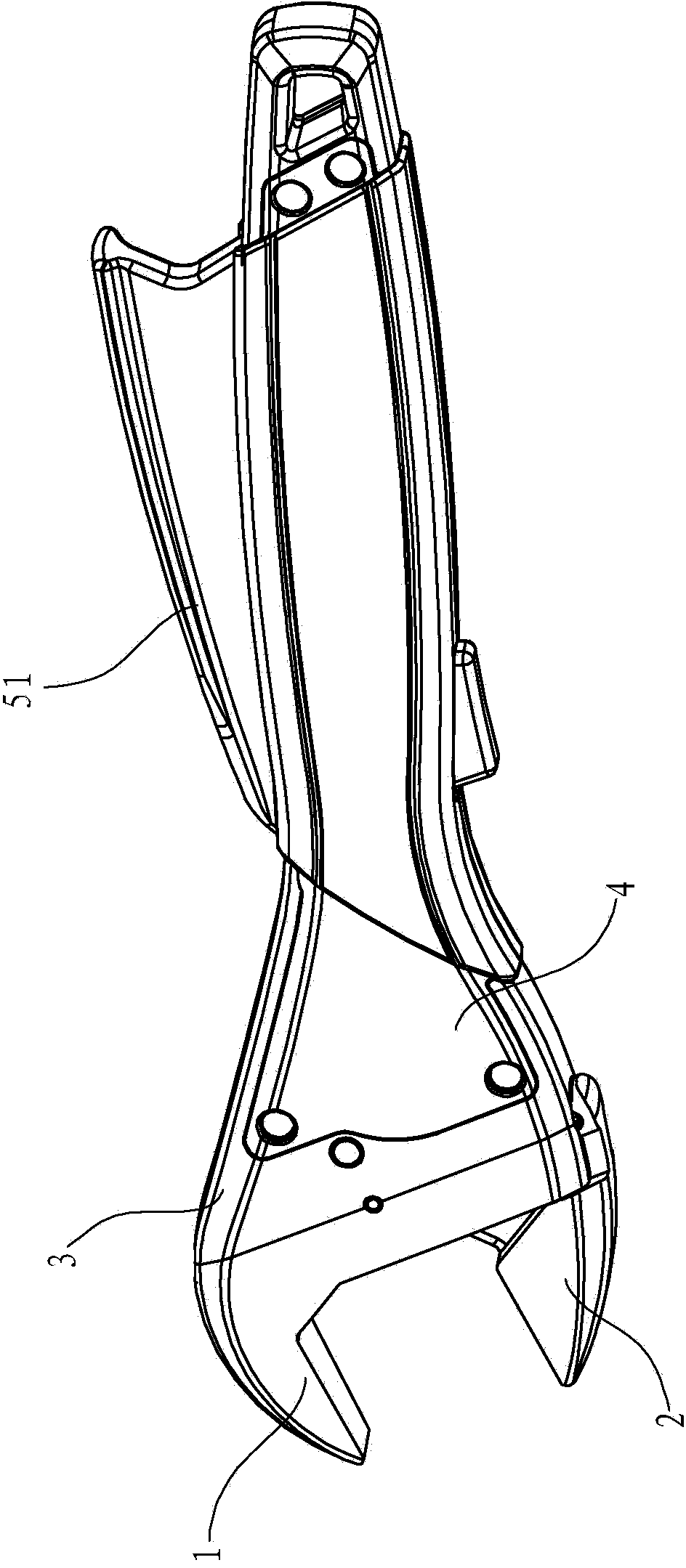

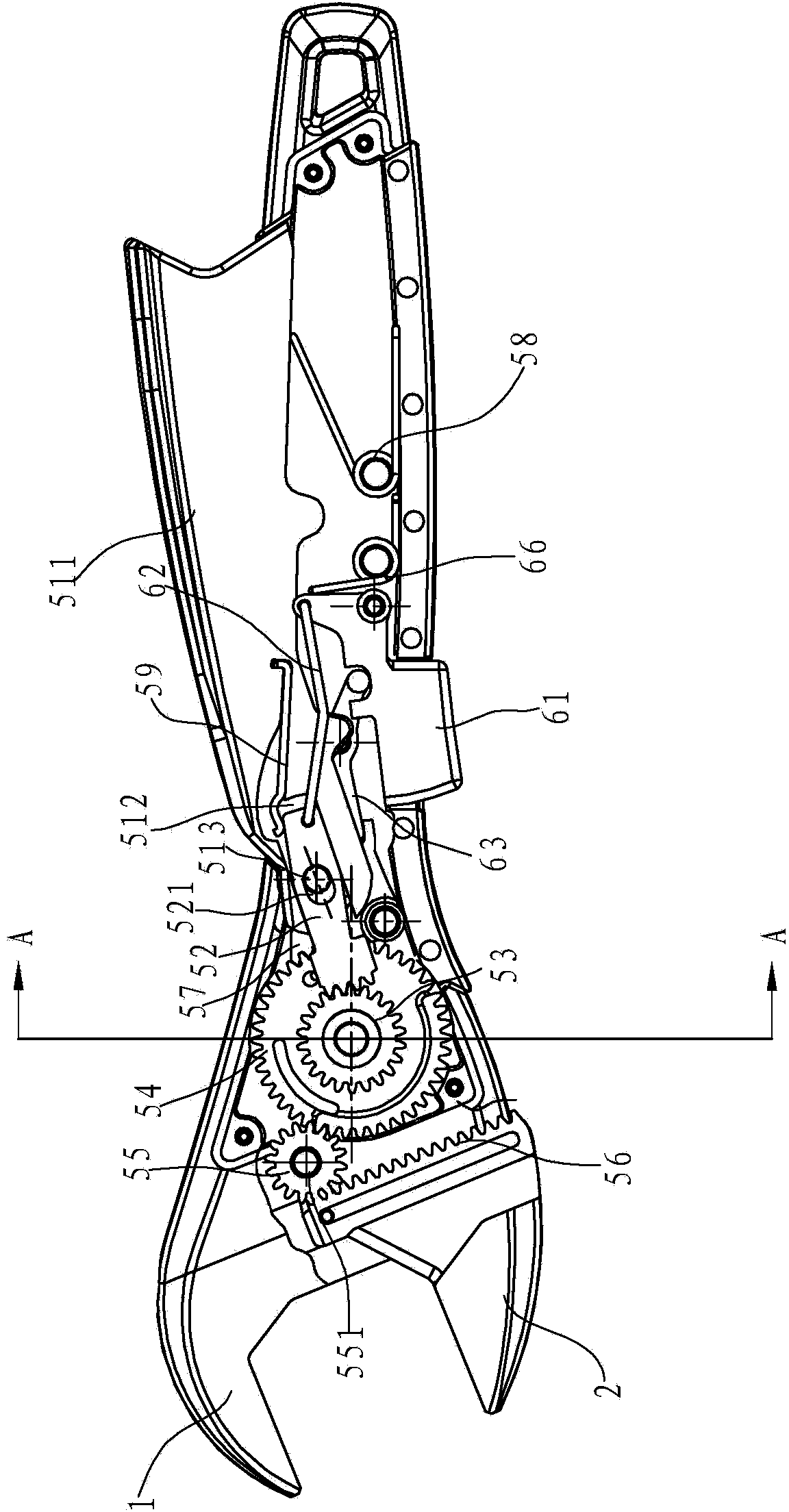

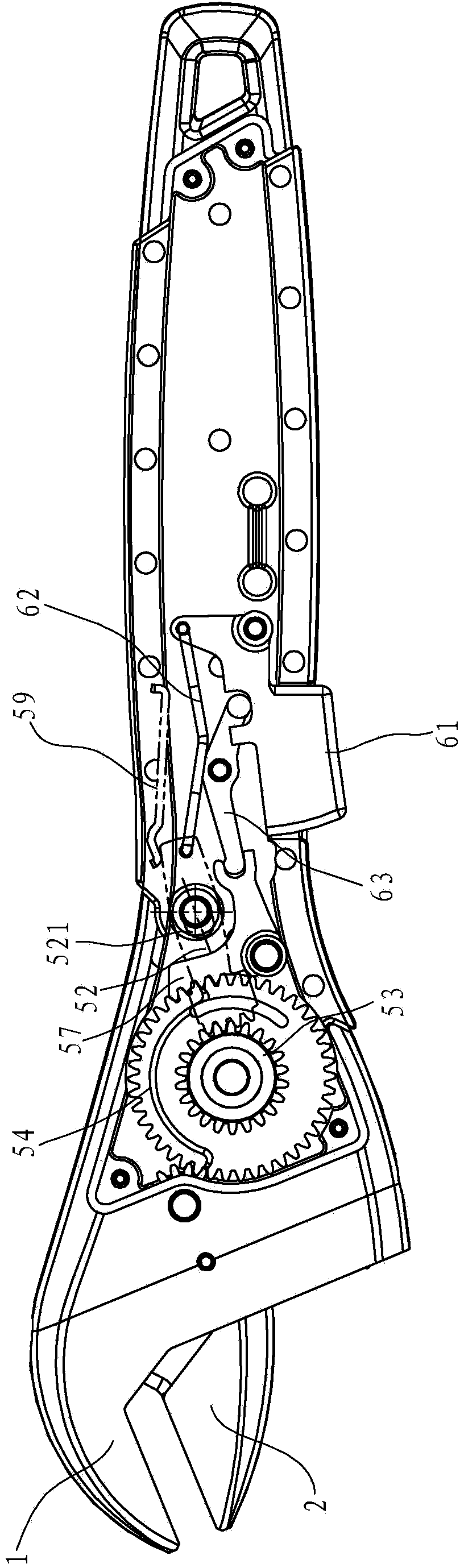

[0022] see figure 1 , a wrench, comprising an upper jaw 1 and a lower jaw 2, the lower jaw 2 is driven by a feed mechanism to move in the direction of the upper jaw 1, and the lower jaw 2 is driven by a reset mechanism to return to an initial position, the feed mechanism and the reset The mechanism is housed within the wrench housing formed by housing 3 and housing cover 4 .

[0023] For the convenience of description, hereinafter, the terms "front end (front)" and "rear end (rear)" are used, "front end (front)" refers to the end close to the object to be operated, and "rear end (rear)" Refers to the end away from the operand.

[0024] see figure 2 with Figure 5 , the feed mechanism includes a feed trigger 51, the feed trigger 51 includes a pressing portion 511 extending out of the wrench housing, the front end of the feed trigger 51 loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com