Nozzle device of 3D (Three-dimensional) printer

A 3D printer and nozzle technology, applied in the field of 3D printer nozzle devices, can solve the problem that 3D printers cannot achieve color printing, etc., and achieve the effect of easy promotion and affordable price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

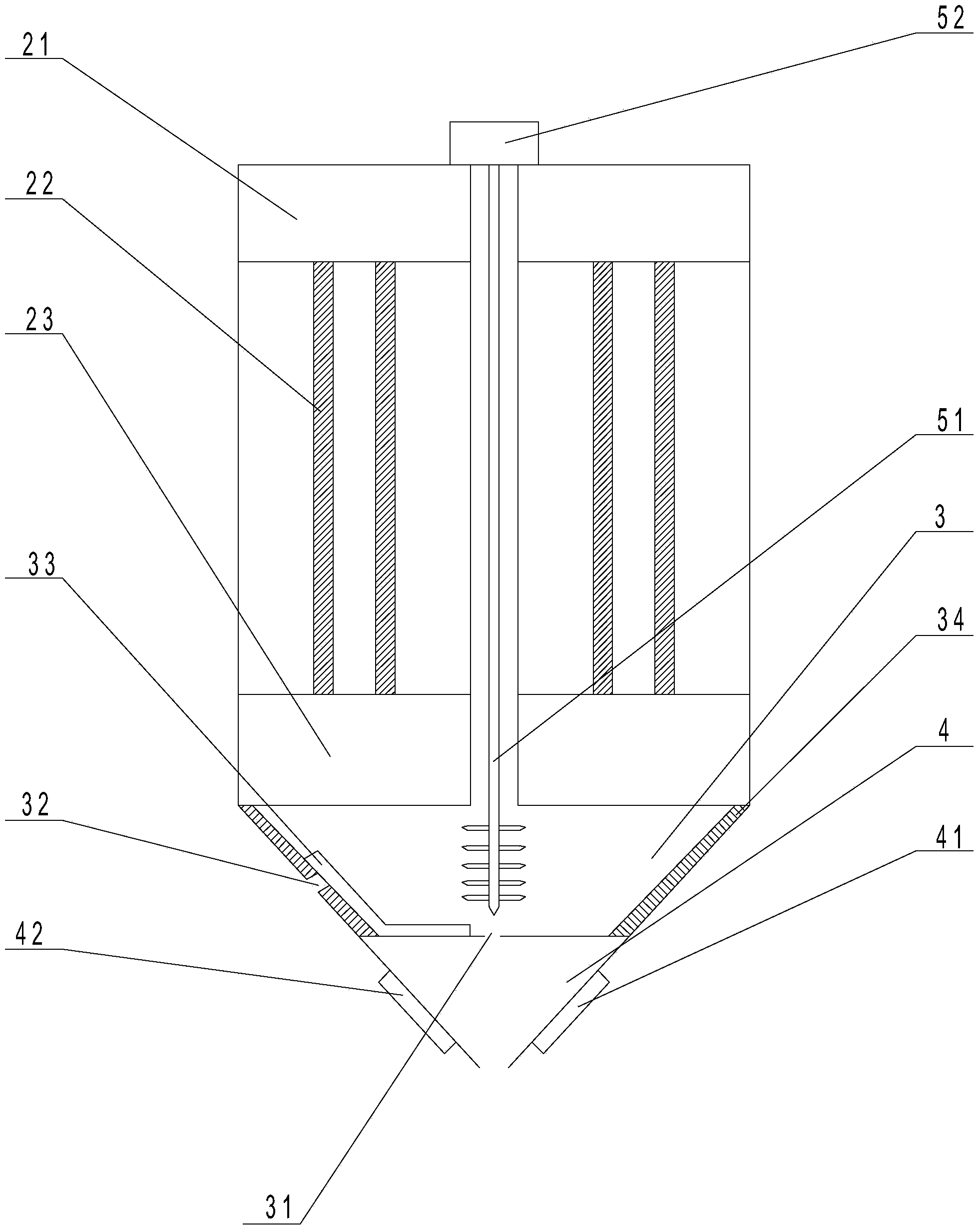

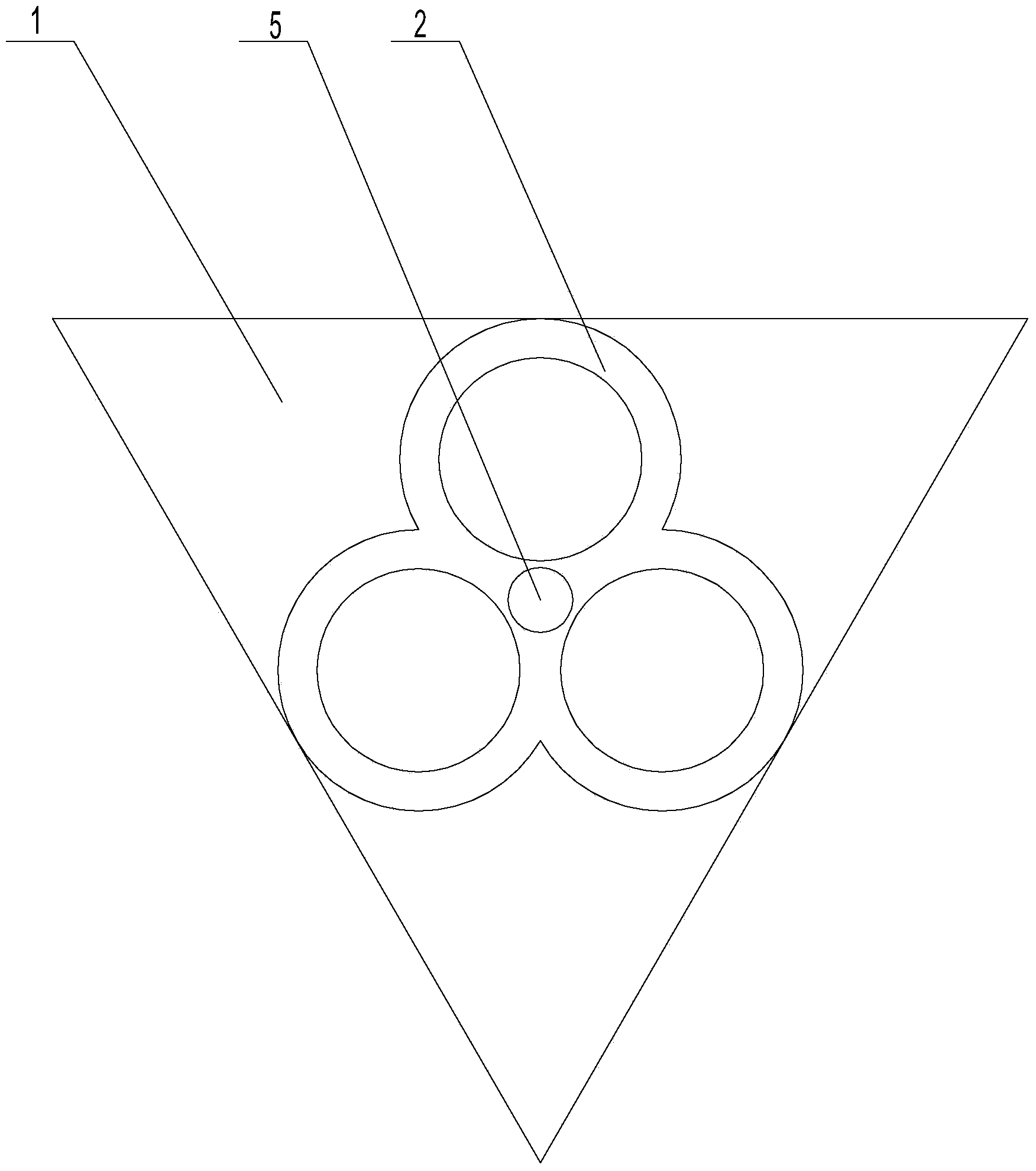

[0018] Such as figure 1 to combine figure 2 As shown, a 3D printer nozzle device, the nozzle device includes a housing 1, the housing 1 is provided with a three-color chamber 2, a mixing chamber 3 and a nozzle 4 in sequence from top to bottom; the three-color chamber 2 is composed of three Each chamber is composed of three separate independent chambers, each of which is passed through one of the three primary colors of plastic wire, and each chamber is equipped with a transmission device 21, a heating device 22 and an electric valve 23; the three-color chamber 2 A pressurized chamber 5 is provided at the center, and the pressurized chamber 5 communicates with the mixing chamber 3, and a stirring fin 51 is arranged in the described pressurizing chamber 5, and the stirring fin 51 extends into the mixing chamber 3; The mixing chamber 3 and the nozzle 4 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com