Method for automatically shearing braid

A tape cutting and automatic technology, which is applied in the directions of automatic packaging control, packaging, packaging protection, etc., can solve the problems of tape braiding machines not working normally, defective products and products, low production efficiency, etc., and achieve a high degree of automation and improve The effect of quality and labor cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

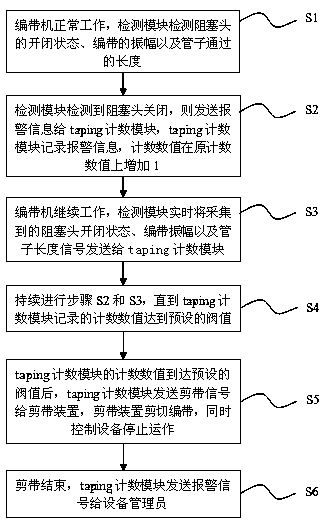

[0023] Such as figure 1 Shown, a kind of automatic tape cutting method, it comprises the following steps:

[0024] S1: The braiding machine is working normally, and the detection module detects the opening and closing state of the blocking head, the amplitude of the braiding and the length of the pipe;

[0025] S2: The detection module detects that the blocking head is closed, then sends an alarm message to the taping counting module, and the taping counting module records the alarm message, and the count value is increased by 1 on the original count value;

[0026] S3: The taping machine continues to work, and the detection module sends the collected opening and closing state of the blocking head, braiding amplitude and pipe length signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com