Multifunctional pipe hoisting machine

A pipelayer and multi-functional technology, which is applied to cranes, earthmovers/shovels, mechanically driven excavators/dredgers, etc., to achieve the effects of simple structure, reduced counterweight weight, and easy manufacturing and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

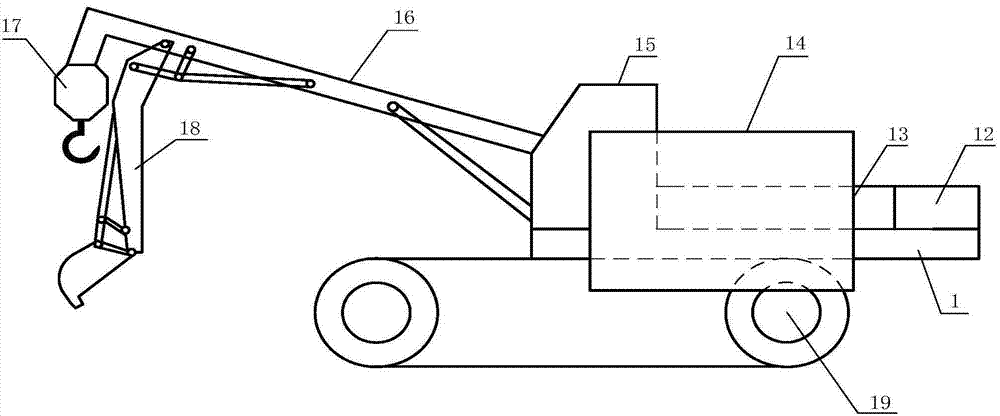

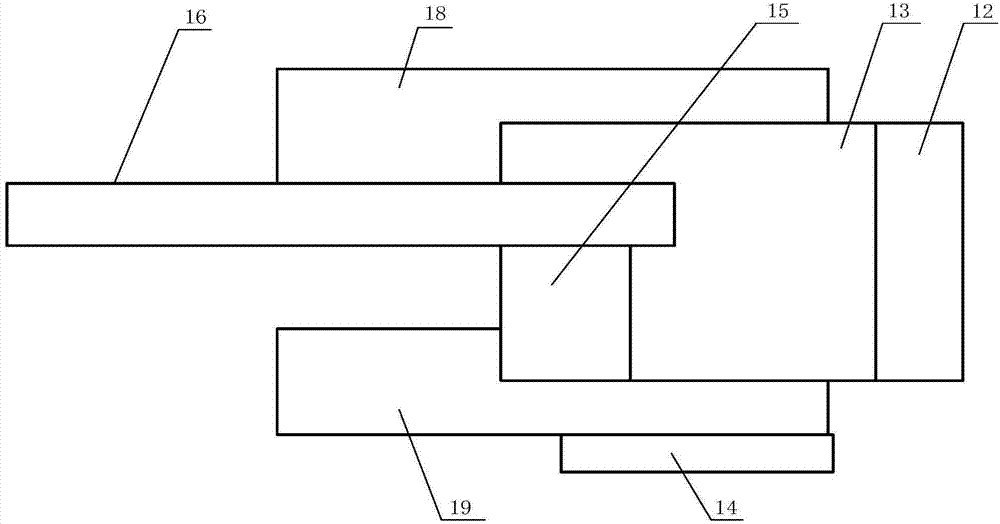

[0016] Such as figure 1 and figure 2 As shown, the multifunctional pipelayer of the present invention includes: a rotating base 1, a mobile counterweight device 12, an engine 13, a back pipe device 14, a cab 15, a boom 16, a hook 17, an excavating device 18 and a walking device 19. A rotating base 1 is installed on the walking device 19, a cab 15 and a boom 16 are installed on the front end of the rotating base 1, and a mobile counterweight device 12 is installed on the rear end of the rotating base 1. Engine 13 is housed between cab 15, and suspension hook 17 is equipped with on the boom 16, and digging device 18 is also housed on boom 16, and the concrete content of digging device 18 is disclosed with Chinese patent CN102322079A "A working device with both digging and lifting functions" is the same; a back pipe device 14 is installed on the walking device 19 close to the cab 15; Governing Body" is the same.

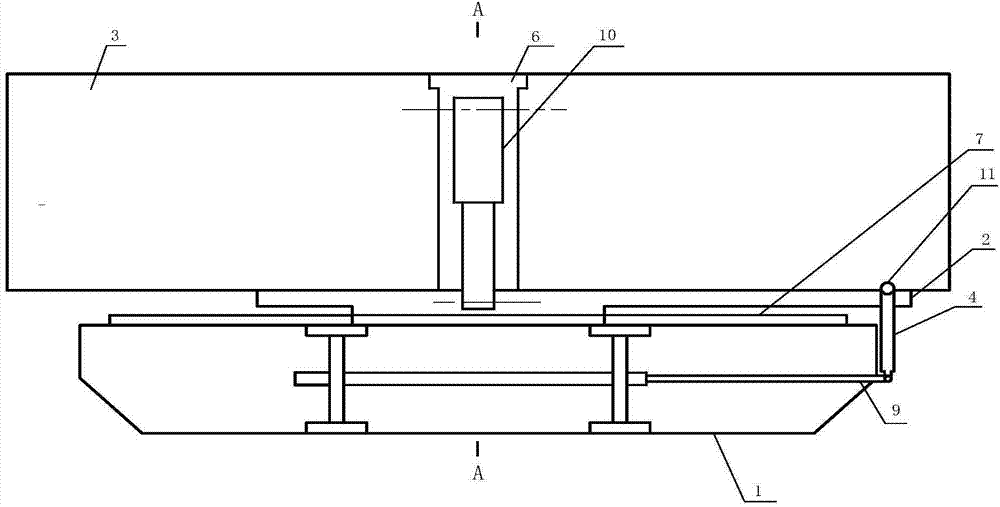

[0017] Such as image 3 and Figure 4 As shown, the mobile c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com