Turning device and turning method for heavy equipment in nuclear power plant

A technology for heavy equipment and turning devices, which is applied in the direction of hoisting devices and hoisting devices, which can solve the problems of cumbersome assembly and disassembly, large space occupied by turning tools, high labor intensity, etc. The effect of duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

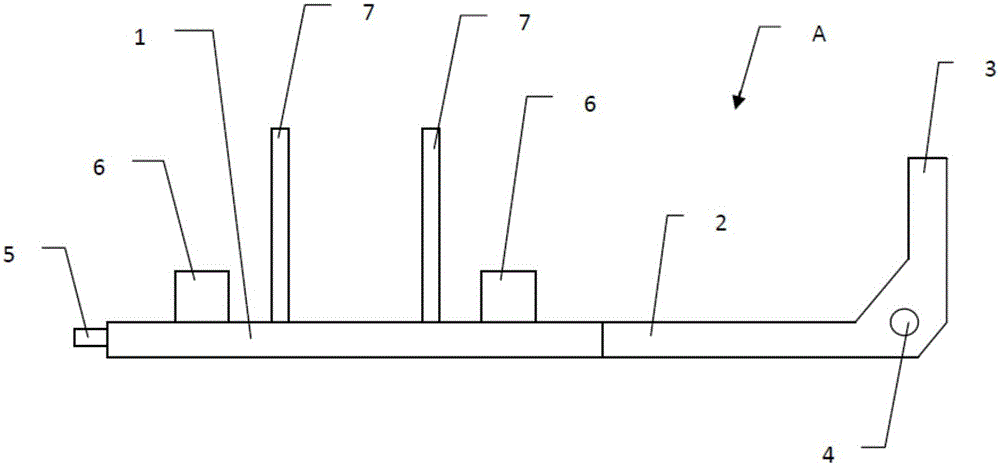

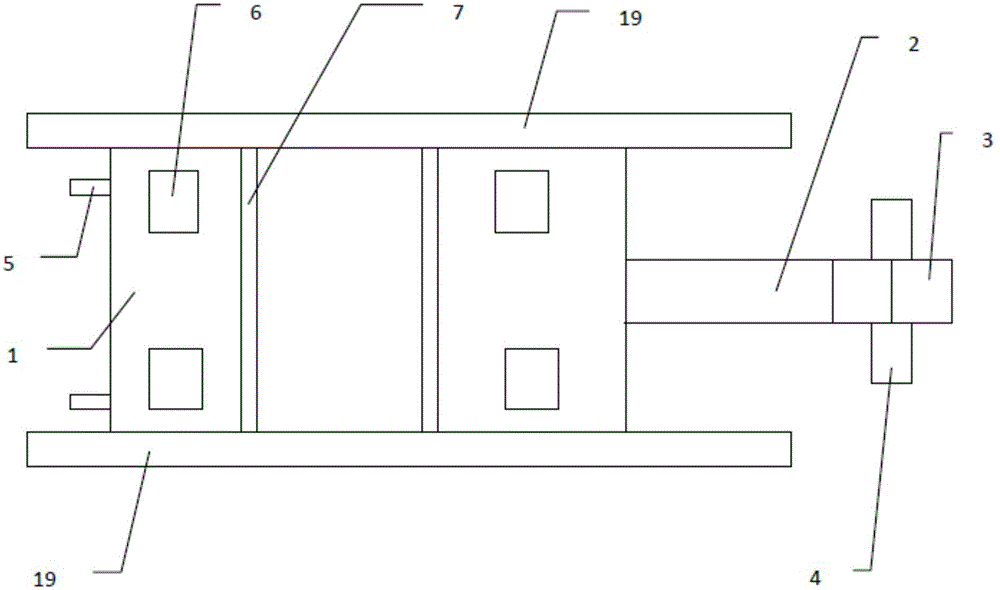

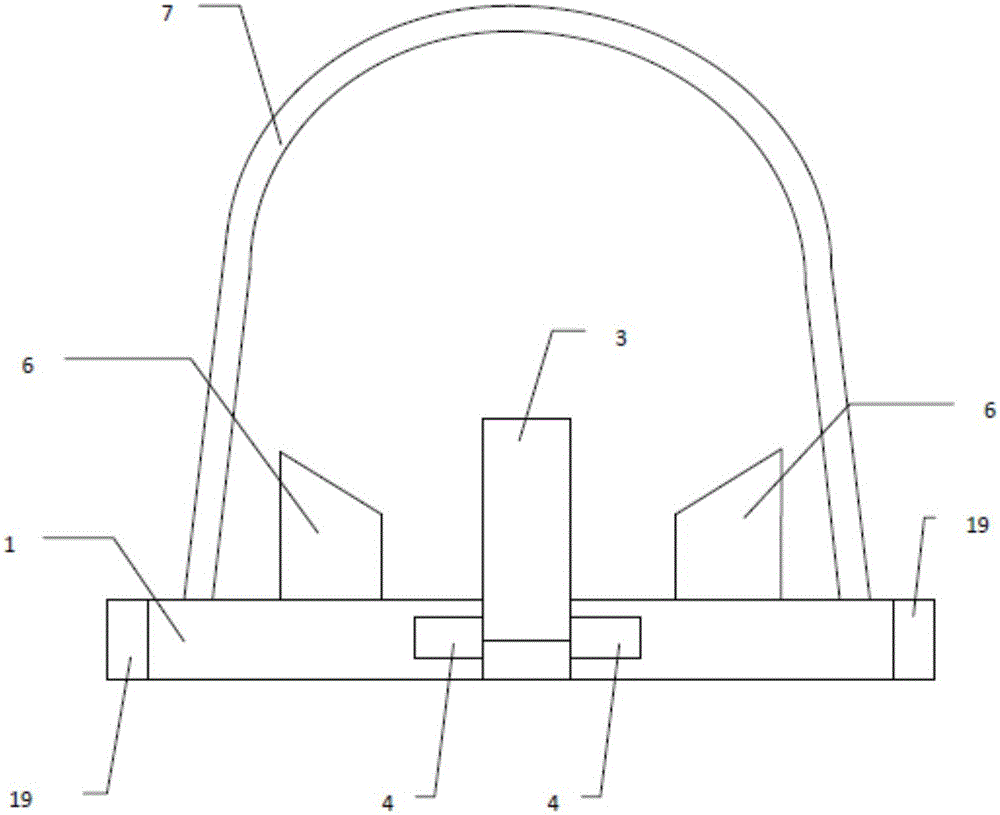

[0098] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0099] The overturning device for heavy equipment in a nuclear power plant provided by the present invention includes a bracket A, an overturning bracket B, a pre-embedded device C and a fastening device D. Through the cooperation of the bracket A and the overturning bracket B, the pre-embedded device C and the fastening device D, Capable of overturning heavy equipment.

[0100] Such as Figures 1a-1d As shown, the bracket A includes a bracket body 1; the bracket body 1 is provided with a belt 7 and a seat bracket 6 for fixing a heavy equipment 16 . Wherein, the belt 7 is provided with an inverted chain lifting point for assembling and dismounting the belt, and the end of the belt 7 can be fixed on the bracket body 1 through an anchor device; one end of the bracket body 1 is provided with a lifting lug for hanging a hoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com