Sludge drying machine

A sludge drying and drying technology, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of high water content of sludge on the sludge inlet side, rail gnawing, and low resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

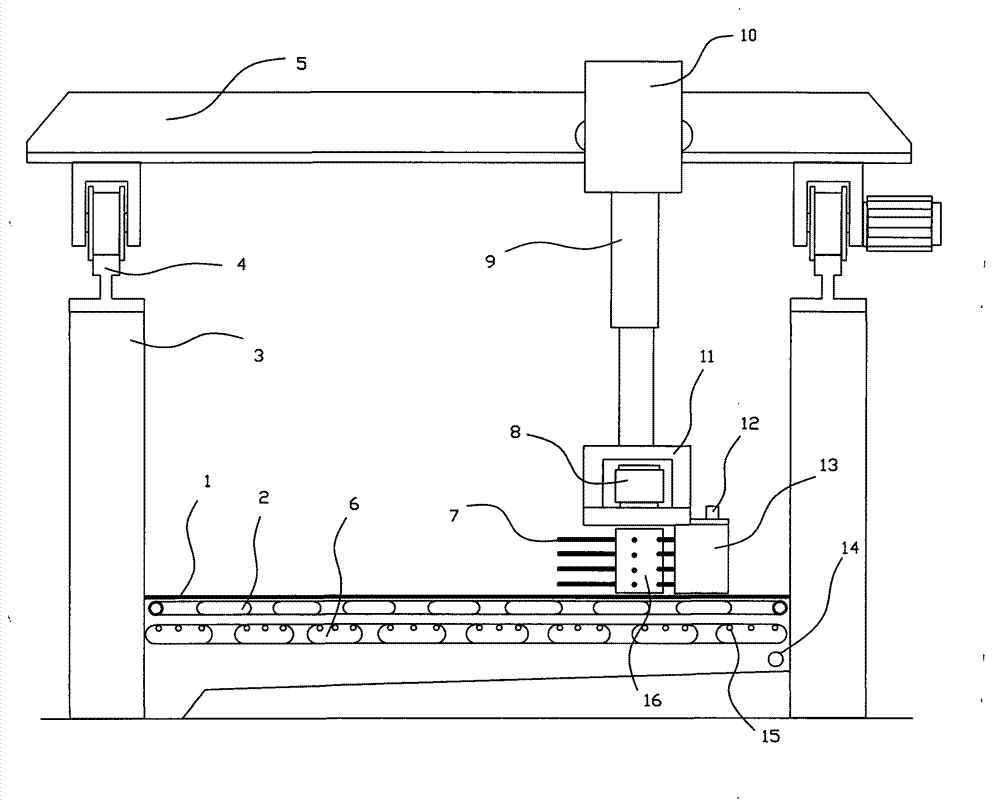

[0008] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0009] It can be seen from the accompanying drawings that the sludge drying machine of this program has two vertical vertical walls 3, a drying bed is arranged between the two vertical walls 3, and a vertical guide rail 4 is respectively arranged on the upper top surface of the two vertical walls 3 , on two vertical guide rails 4, longitudinal driving 5 is housed, and the drying bed described in this program is that the top surface is made of the bed board 1 that is densely covered with through holes and the heating pipe 2 and the ventilation pipe 6 under the bed board 1. The bed board 1 described in the specific implementation mode of this program adopts a steel plate with densely distributed tiny through holes. The heating pipe 2 described in the specific implementation mode of thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com