Cylindrical seed frying machine

A seed frying machine, cylindrical technology, applied in the direction of fat production, fat oil/fat production, etc., can solve the problems of high labor intensity, low work efficiency, elimination, etc., to improve the working environment, high work efficiency, and improve safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

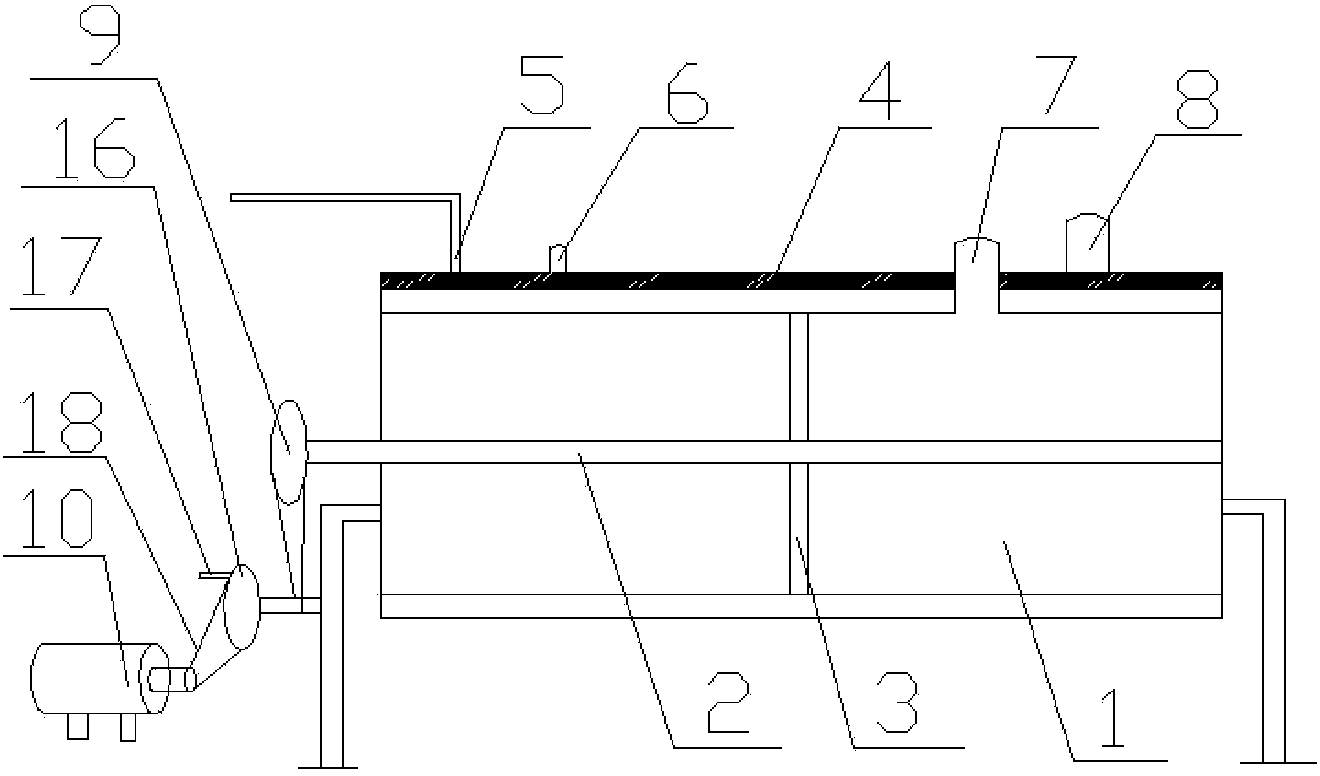

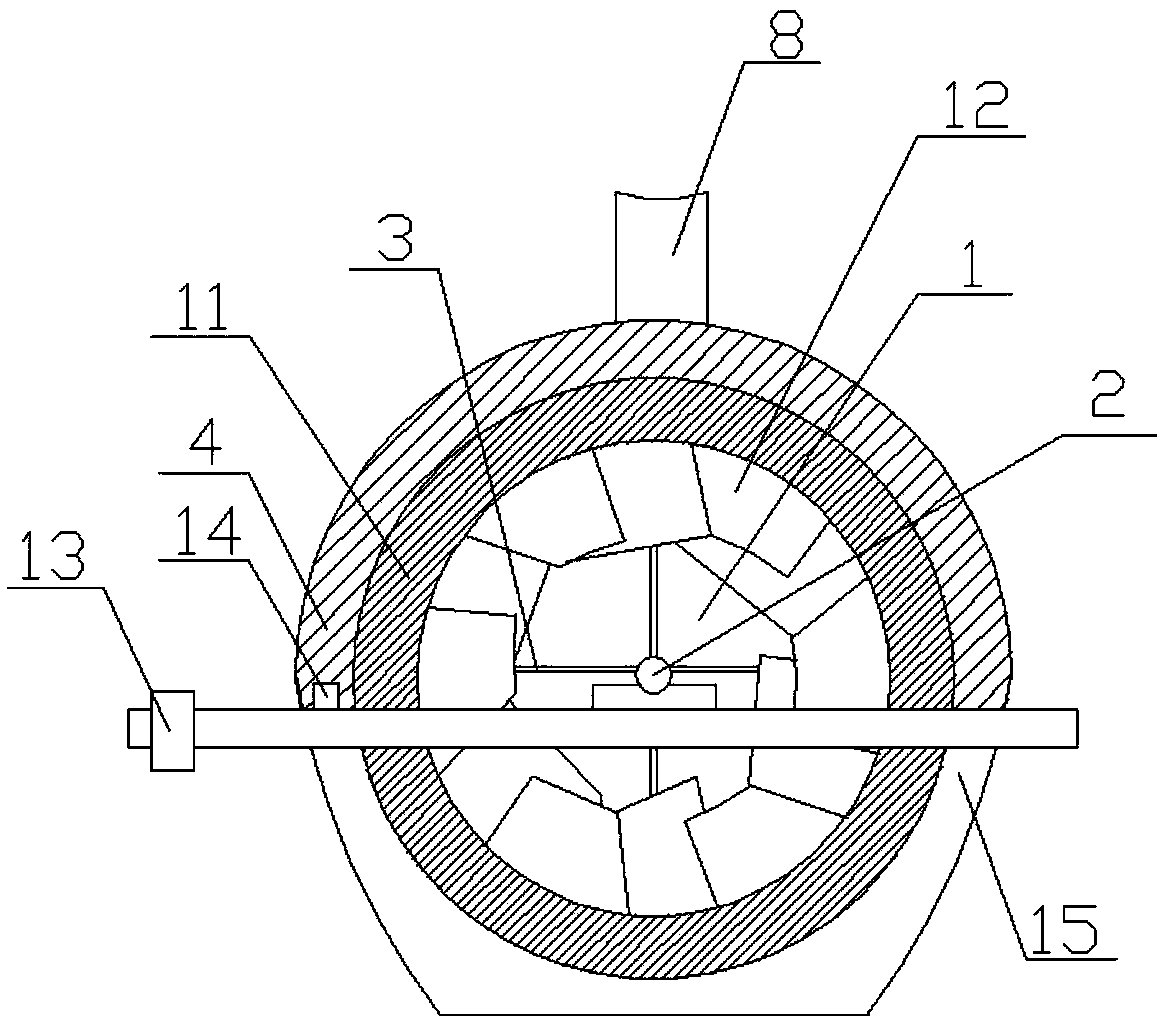

[0019] See Figure 1~2 As shown, the cylindrical seed frying machine includes a cylinder body 1 and a main shaft 2. A converter 11 is arranged inside the cylinder body 1. An interlayer 4 is arranged between the cylinder body 1 and the converter 11. One end of the cylinder body 1 is closed, and the cylinder body 1. The other end is provided with a feed port, and the bottom of the cylinder 1 is also provided with a refractory stove 15. The main shaft 2 penetrates the inside of the cylinder 1. The end of the main shaft 2 passing through the closed end of the cylinder 1 is connected with a transmission device. The inner wall of the converter 11 The supporting part is connected with the main shaft 2 , and the inner wall of the converter 11 is provided with a frying plate 12 , and the frying plate 12 is evenly arranged on the inner wall of the converter 11 in a spiral shape.

[0020] The supporting member is a connecting rod 3 that fixes the main shaft 2 to the inner wall of the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com