A transmission device for drive shaft of cutter head of farmland ditching machine

A cutter head drive and transmission technology, which is applied to transmission parts, mechanical equipment, earth movers/shovels, etc., can solve the problems of poor adjustment and inconvenient use, and achieve reasonable installation and reduced drive. The consumption of power, the effect of reliable adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

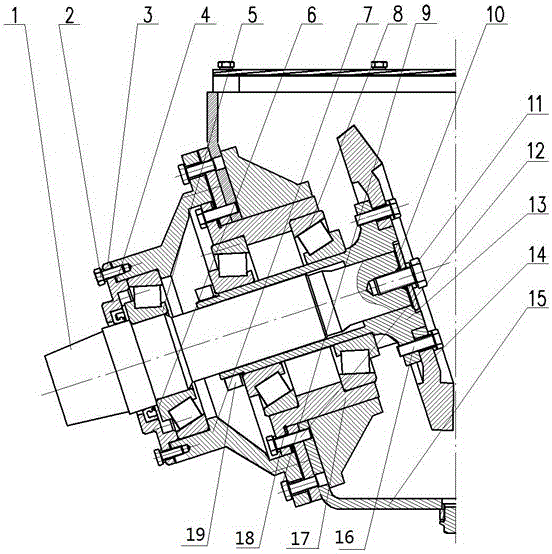

[0012] As shown in the figure, the specific implementation method is as follows:

[0013] A transmission device for the drive shaft of a farmland ditching machine cutter head, including a drive shaft assembly for providing power, a reducer for adjusting and outputting power, and a bearing for installing the drive shaft assembly on the reducer housing 15 Seat assembly, the bearing seat assembly includes a bearing seat 17 and a bearing support sleeve 13, the bearing support sleeve 13 is assembled on the bearing seat 17 through a pair of tapered roller bearings 8, and the bearing seat 17 is fixed on the reducer housing 15 One end of the bearing support sleeve 13 is connected to the spiral bevel gear 14 in the reducer, and the other end is provided with a fastening nut 19 for adjusting the preload of the tapered roller bearing 8. The drive shaft assembly The output end of the middle drive shaft 1 penetrates from the end of the bearing support sleeve 13 provided with a fastening nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com