A similar simulation method for grouting filling in the caving area of broken roof

A similar simulation and broken roof technology, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve the problems of uncontrollability, reducing the movement space of overlying strata, and not being able to simulate the broken roof well with mining and popping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

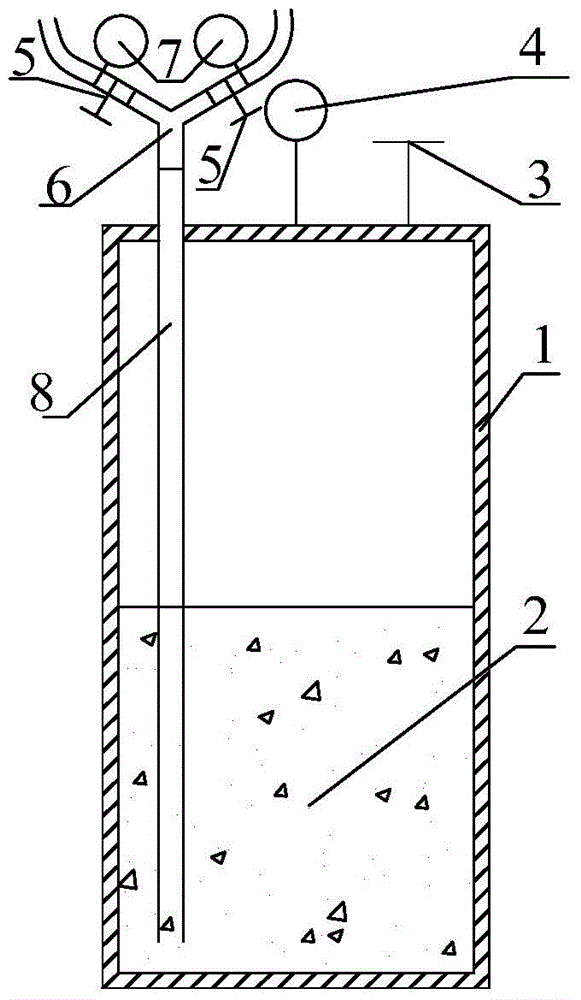

Examples

Embodiment 1

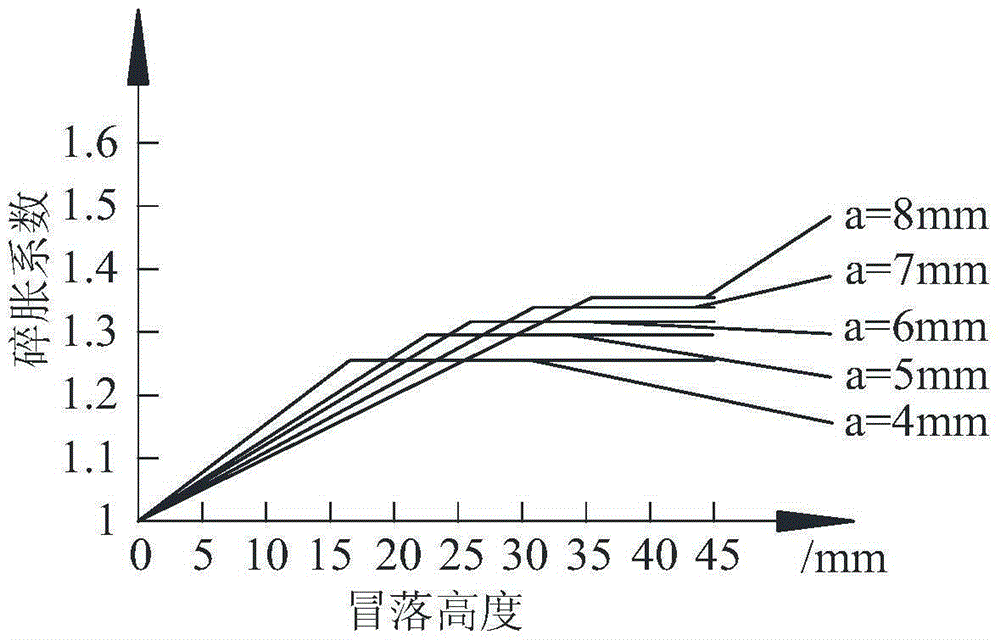

[0045] The coal occurrence conditions of a certain seam in a certain mine are as follows: the thickness of the coal seam is m = 3m, and the thickness of the immediate roof is m z= 4m, direct topping rock breaking expansion coefficient K = 1.3, and the initial pressing step distance of the adjacent working face is c 0 = 40m, the periodic pressure step is c = 12m, the rock beam is relatively stable at the periodic pressure stage b = 8m, and the length of the filling branch in the goaf is 10m.

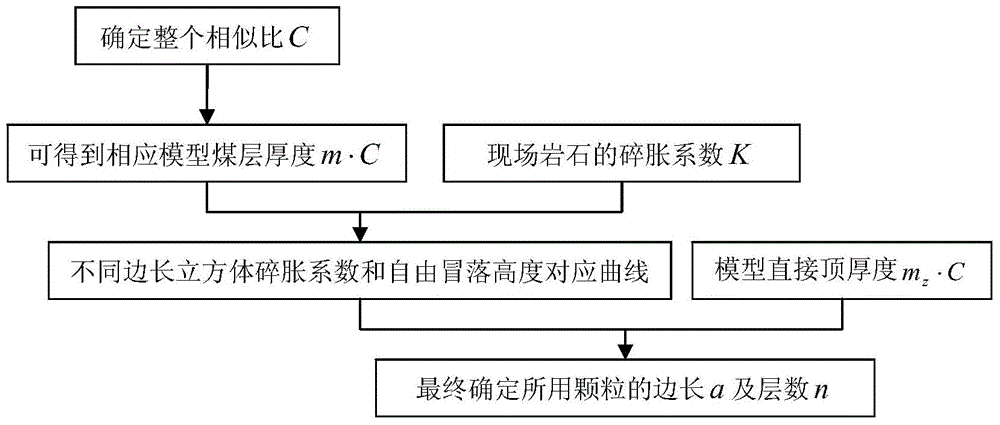

[0046] 1. The design and laying of the model, the process is as follows:

[0047] ①Determine the geometric similarity ratio C=1 / 100 of the similar simulation test model;

[0048] ② Lay the coal seam floor and coal seam according to the similar material ratio and laying plan;

[0049] ③ It is used to simulate the determination and laying of the side length a and the number of layers n of the direct roof cube. The process is as follows:

[0050] A. Coal seam thickness m=3m, direct roof t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com