Shock-absorbing automobile manual gear shift manipulator

A technology of variable speed manipulator and car hand, applied in the direction of components with teeth, non-rotational vibration suppression, belt/chain/gear, etc., can solve the problems of manipulating handle shaking, increasing vehicle use cost, and gear loss, etc., to achieve Flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

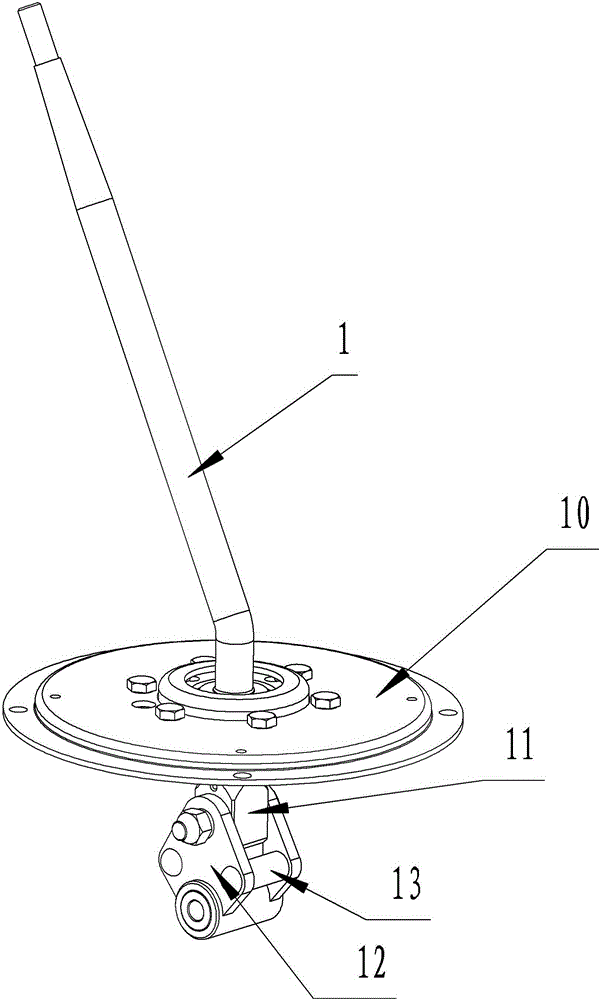

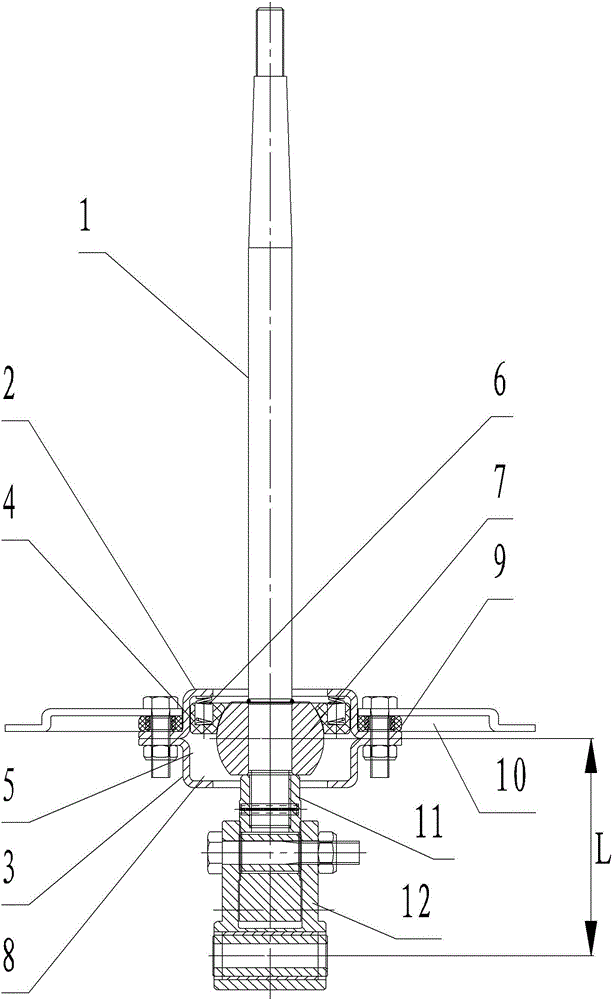

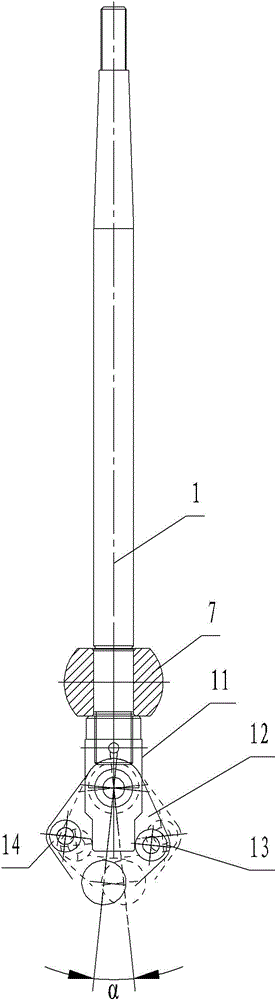

[0013] According to attached Figure 1~3 , a shock-absorbing automobile manual transmission manipulator of the present invention is a combined swing arm composed of a main swing arm and a secondary swing arm. The main swing arm is installed on the center of the disc-shaped base 10, and the secondary swing arm is installed at the lower end of the main swing arm. . The main swing arm includes a joystick 1, a first bearing holder 2, a second bearing holder 3, a first bearing inner sleeve 4, a second bearing inner sleeve 5, a spring 6, a steel ball with a hole 7 and a bearing pad 8, and a bearing pad 8 After the upper end is attached with a buffer sheet 9, it is vertically fixed at the center of the disc-shaped base 10. The lower end of the joystick 1 is connected with the auxiliary swing arm 12 through the connector 11, and the first installation positioning sleeve 13 and the second installation positioning sleeve 14 arranged on both sides of the auxiliary swing arm 12 make the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com